Description

Jiangsu Liangyi professional manufacturer of 05Ch16N4D2B - 05Х16Н4Д2Б- 07Ch16N4D4B - 07Х16Н4Д4Б - 07Ch14N4DB - 07Х14Н4ДБ open die forging parts and seamless rolled steel forged rings from china

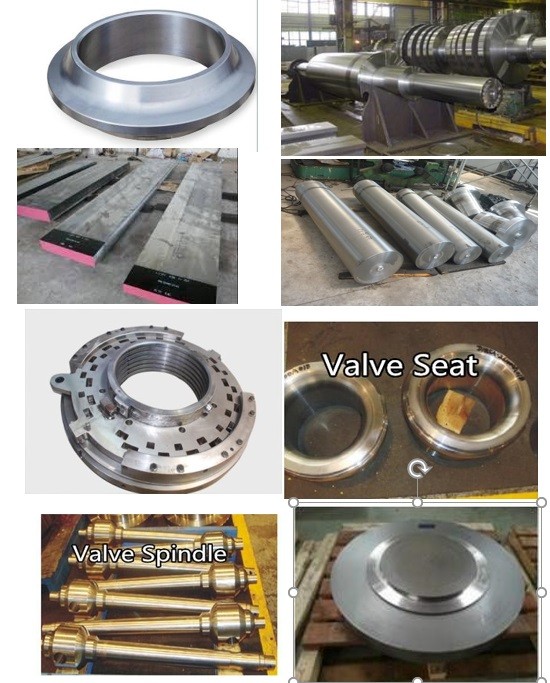

Following is the shape of 05Ch16N4D2B - 05Х16Н4Д2Б- 07Ch16N4D4B - 07Х16Н4Д4Б - 07Ch14N4DB - 07Х14Н4ДБ forging steel material that we could do is:07Ch16N4D4B Forged Steel round bars square bars Flat bars Rectangles Bars Rods,05Ch16N4D2B Forged forging steel rings seamless rolled rings,05Х16Н4Д2Б Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,07Ch14N4DB Forged Forging Steel Discs Disks Blocks plates,,07Х14Н4ДБ Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 05Ch16N4D2B - 05Х16Н4Д2Б- 07Ch16N4D4B - 07Х16Н4Д4Б - 07Ch14N4DB - 07Х14Н4ДБmaterial that is used in following industry

05Ch16N4D2B Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

05Х16Н4Д2Б Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

07Ch16N4D4B Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

07Ch14N4DB Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

07Х16Н4Д4Б forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

07Х16Н4Д4Б Forged Forging ultra high pressure water jet Waterjet cutting Machine Cutter Hydraulic Cylinder,accumulator attenuator

07Х16Н4Д4Б forged steel ultra high pressure water jet Waterjet cutting Machine Cutter intensifier pump Sealing Heads

05Ch16N4D2B Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate pump

07Ch14N4DB Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

07Ch14N4DB forged steel Mechanical Seal Discs

07Х16Н4Д4Б forging steelPost Tensioning Bars

05Ch16N4D2B forging steel Gear Timing Adapter Plates

07Х16Н4Д4Б Forged Forging Marine Ship Boat Propeller Shafts

07Х16Н4Д4Б forged steel Pressure Port Sensor housing

05Х16Н4Д2Б Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

07Ch16N4D4B Forged Forging Gas Air Compressor Rotor

07Ch14N4DB Forged Forging Steels Christmas Trees wellhead Spool Body Bodies cylinder

05Ch16N4D2B Forged Forging Block Adaptor

05Ch16N4D2B Forged Forging venturi cone meter Body Bodies Blocks

05Х16Н4Д2Б Forged Forging Steel frac pumps Fluid End Body Bodies Blocks Modules

07Ch14N4DB Forged Forging Steel gate valves Body Bodies bespoke flat bars

07Ch14N4DB Forged Forging Steel drill head casings,collars,landing bowls

05Ch16N4D2B forging forged steel Couplings

05Ch16N4D2B forged steel Flowseal cryogenic High Performance BV Butterfly Valves HPBV shaft

05Ch16N4D2B forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

05Ch16N4D2B Forged Forging Steel Subsea X Tree high pressure elbow

05Х16Н4Д2Б forged forging Steel wellhead locknut Venturi Bench

05Х16Н4Д2Б Forged Forging Steel double studded adapter flange

05Х16Н4Д2Б Forged Forging Steel integral Mud Flange Flanged outlet Studded crosses

05Х16Н4Д2Б forged steel Downhole drilling tool Mud Motor End Caps

05Х16Н4Д2Б Forged Forging Steel Casing Heads,Tubing Heads,Casing Hangers,Tubing Hangers,Tubing Spools,Casing Spools,Spacer Spools

05Х16Н4Д2Б Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

05Х16Н4Д2Б forging Stainless Steel Intake Gate Hoist Cylinder Piston Rods

07Ch16N4D4B Forged Forging Steel Pressure Vessel STUDDING OUTLET

07Ch14N4DB Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

07Ch16N4D4B forging Forging/Forged Steel Wellhead Christmas Tree Frac Head (Fracturing Head)

05Ch16N4D2B Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

05Х16Н4Д2Б Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings

07Ch16N4D4B Forged Forging forge Steel transition Cone

07Ch14N4DB Forged Forging Blowout Preventer RAM Annular dual Bops Body Bodies Block

05Ch16N4D2B forged forging steel Load Cell

07Х16Н4Д4Б forging steel Homogeniser Homogenising Pumping pistons Plunger

07Х16Н4Д4Б forged Steel Culvert Valve Piston Rods for Miter Gate

05Ch16N4D2B forging steel Hydraulic Cylinder Piston Rod For Miter Gate Machinery

07Х16Н4Д4Б forged forging steel Tainter Valve Main Rod and Piston Rod

05Ch16N4D2B Forged Forging Duplex Stainless Steel Subsea Manifolds

05Ch16N4D2B - 05Х16Н4Д2Б- 07Ch16N4D4B - 07Х16Н4Д4Б - 07Ch14N4DB - 07Х14Н4ДБ is a chromium-nickel-copper precipitation-hardening martensitic stainless steel with an addition of niobium. 05Ch16N4D2B - 05Х16Н4Д2Б- 07Ch16N4D4B - 07Х16Н4Д4Б - 07Ch14N4DB - 07Х14Н4ДБ combines high strength and hardness with good corrosion resistance.

The alloy is furnished in the solution annealed condition . It should not be used at temperatures above 572°F (300°C) or for cryogenic service. Optimal mechanical properties can be obtained by subjecting the alloy to age hardening heat treatments. Heat treatment in the 900°F (482°C) range produces the highest strength.

FOllowing is chemical compostion of 05Ch16N4D2B - 05Х16Н4Д2Б- 07Ch16N4D4B - 07Х16Н4Д4Б - 07Ch14N4DB - 07Х14Н4ДБ forged steel sleeves

C (Углерод) < 0.07

Si (Кремний) < 0.8

Mn (Марганец) < 1.8

P (Фосфор) < 0.03

S (Сера) < 0.03

Cr (Хром) 15.0 - 17.5

Ni (Никель) 2.0 - 5.0

Nb (Ниобий) 0.05 - 0.50

Cu (Медь) 1.5 - 3.0

Fe (Железо) ОстальноеFollowing of 05Ch16N4D2B - 05Х16Н4Д2Б- 07Ch16N4D4B - 07Х16Н4Д4Б - 07Ch14N4DB - 07Х14Н4ДБ forging parts mechnical property :

Предел текучести: 880 - 1370 МПа Относительное удлинение: 10 - 12 % Ударная вязкость KCU при 20°C: 69.0 - 78.5 Дж/см2 Относительное сужение: 50 - 52 % Диаметр отпечатка: 2.8 - 3.6 мм

Прутки Предел текучести: > 1570 МПа Относительное удлинение: > 9 % Ударная вязкость KCU при 20°C: > 69 Дж/см2 Относительное сужение: > 50 % Диаметр отпечатка: 2.8 - 3.2 мм Твёрдость HBW: 363 -479

For our finished production of 05Ch16N4D2B - 05Х16Н4Д2Б- 07Ch16N4D4B - 07Х16Н4Д4Б - 07Ch14N4DB - 07Х14Н4ДБ forged steel bars should have following inspection report

Identification number, material number and designation, order number, drawing number,

Specification Number;

- Heat number, heat chemical analysis, melting method and product chemical analysis;

- Certificate of heat treatment including method of cooling, actual part temperature, holding

time, cooling condition and all re-heat-treatments by complete graphic temperature time;

- Nondestructive testing records,

- Results of all Mechanical Tests,

-Results of residual stress measurements (for process qualification),

- All probable deviation reports,

- Certification of NDT inspector,

- Dimensional and visual inspection report,

- Cleaning Verified

All our 05Ch16N4D2B - 05Х16Н4Д2Б- 07Ch16N4D4B - 07Х16Н4Д4Б - 07Ch14N4DB - 07Х14Н4ДБ forging patys can be release in 10204-3.2 certificate by following third party DNV-GL BUREAU VERITAS,LLOYD’S REGISTER,ABS, RINA,TÜV

Welcome your inquiry of 05Ch16N4D2B - 05Х16Н4Д2Б- 07Ch16N4D4B - 07Х16Н4Д4Б - 07Ch14N4DB - 07Х14Н4ДБ forging forged steel parts