Description

Jiangsu Liangyi is professional manufacturer of Maraging 250,VASCOMAX 250,UNS K92890,Maraging C-250 C250 open die forging parts and seamless rolled steel forged rings from china

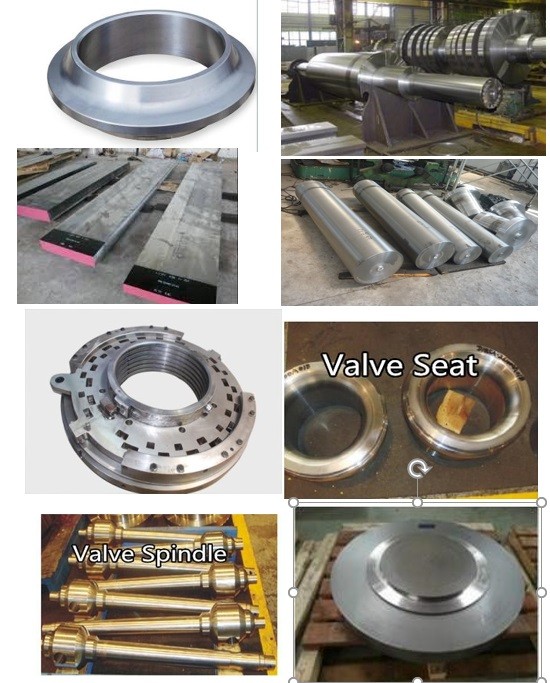

Following is the shape of Maraging 250,VASCOMAX 250,UNS K92890,Maraging C-250 C250 forging steel material that we could do is: Maraging 250 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Maraging 250 Forged forging steel rings seamless rolled rings,Maraging 250 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,Maraging 250 Forged Forging Steel Discs Disks Blocks plates,Maraging 250 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of Maraging 250,VASCOMAX 250,UNS K92890,Maraging C-250 C250 material that is used in following industry

VASCOMAX 250 Forged Forging Turbine and Compressor Labyrinth Shaft Seals

Maraging 250 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

VASCOMAX 250 Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

Maraging C-250 Forged Forging Steel Butterfly Valve Main Shafts Spindles

Maraging 250 Forged Forging Gas Air Compressor Rotor

VASCOMAX 250 Forged Forging venturi cone meter Body Bodies Blocks

Maraging 250 Forged Forging Steel gate valves Body Bodies bespoke flat bars

Maraging 250 forged steel Flowseal cryogenic High Performance BV Butterfly Valves HPBV shaft

Maraging 250 forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

Maraging C-250 Forged Forging Steel double studded adapter flange

Maraging C-250 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

Maraging C-250 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

Maraging C-250 Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

Maraging C-250 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

VASCOMAX 250 Forged Forging forge Steel transition Cone

Maraging 250 Forged Forging Steel Pressure Vessel Reactor Nozzles

VASCOMAX 250 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

VASCOMAX 250 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs,turbine wheel discs

Maraging C-250 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

Maraging C-250 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

Maraging C-250 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

Maraging 250 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

Maraging 250 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

Maraging 250 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

Maraging 250 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

Maraging 250 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

Maraging 250 is an age-hardenable iron-nickel steel. Alloy 250 combines ultra-high strength (1800MPa), good toughness, readily machinable in pre-aged condition, excellent transverse properties and resistance to crack propagation. Maraging C250 is used for missile and ejector systems, slat tracks and drive shafts.

FOllowing is melting methods of Maraging 250 forged parts

Material shall be produced by a triple melt process consisting of vacuum induction melting (VIM)followed by electroslag consumable electrode remelting (ESR)and vacuum arc consumable electrode remelting VAR).

FOllowing is chemical compostion of Maraging 250,Maraging C-250 forged steel rings

C Carbon 0.03 max

Si Silicon 0.10 max

Mn Manganese 0.10 max

Ni Nickel 18.50

Co Cobalt 7.50

Mo Molybdenum 4.80

Ti Titanium 0.40

Al Aluminum 0.10

Fe Iron Balance

Following of Maraging 250,Maraging C-250 forging parts heat treatment nechanical property Delivery condition :

UTS, MPa 1,860

0.2% PS, MPa 1,725

Elongation on 4D, % 12

Charpy notch impact, J 20

All our finish production of Maraging 250,Maraging C-250 forged steel material should will done in Following NDE shall be performed in delivery condition:

- Visual inspection

Material verification test

- 100% UT- inspection according to EN 10228-3 (table 3). Depending on the forging geometry,

following inspection types are applicable:

- for 1.4545 forging bar shape components; type 1 (inspection may also be carried out as per EN10308 for type 1)

- for X5CrNiCuNb15-5 forged discs and plate- like components: type 2

- for X5CrNiCuNb155 forging ring or bushing- like components: type 3b and 3

Following is inspection standard of Maraging 250,Maraging C-250 forging material

ASTM E8 Tension Testing of Metallic Materials

ASTM E38 Chemical Analysis of Nickel-Chromium and Nickei-Chromium Iron Alloys

ASTM E112 Estimating the Average Grain Size of Metals

ASTM E139 Coaducting Creep,Creep-Rupture and Stress Rupture Tests oi Metaliic Materials

ASTM A370 mechanical Testing of Steel Products

Welcome your inquiry of Maraging 250,VASCOMAX 250,UNS K92890,Maraging C-250 C250 forging forged steel parts

Following is the shape of Maraging 250,VASCOMAX 250,UNS K92890,Maraging C-250 C250 forging steel material that we could do is: Maraging 250 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Maraging 250 Forged forging steel rings seamless rolled rings,Maraging 250 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,Maraging 250 Forged Forging Steel Discs Disks Blocks plates,Maraging 250 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of Maraging 250,VASCOMAX 250,UNS K92890,Maraging C-250 C250 material that is used in following industry

VASCOMAX 250 Forged Forging Turbine and Compressor Labyrinth Shaft Seals

Maraging 250 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

VASCOMAX 250 Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

Maraging C-250 Forged Forging Steel Butterfly Valve Main Shafts Spindles

Maraging 250 Forged Forging Gas Air Compressor Rotor

VASCOMAX 250 Forged Forging venturi cone meter Body Bodies Blocks

Maraging 250 Forged Forging Steel gate valves Body Bodies bespoke flat bars

Maraging 250 forged steel Flowseal cryogenic High Performance BV Butterfly Valves HPBV shaft

Maraging 250 forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

Maraging C-250 Forged Forging Steel double studded adapter flange

Maraging C-250 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

Maraging C-250 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

Maraging C-250 Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

Maraging C-250 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

VASCOMAX 250 Forged Forging forge Steel transition Cone

Maraging 250 Forged Forging Steel Pressure Vessel Reactor Nozzles

VASCOMAX 250 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

VASCOMAX 250 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs,turbine wheel discs

Maraging C-250 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

Maraging C-250 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

Maraging C-250 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

Maraging 250 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

Maraging 250 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

Maraging 250 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

Maraging 250 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

Maraging 250 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

Maraging 250 is an age-hardenable iron-nickel steel. Alloy 250 combines ultra-high strength (1800MPa), good toughness, readily machinable in pre-aged condition, excellent transverse properties and resistance to crack propagation. Maraging C250 is used for missile and ejector systems, slat tracks and drive shafts.

FOllowing is melting methods of Maraging 250 forged parts

Material shall be produced by a triple melt process consisting of vacuum induction melting (VIM)followed by electroslag consumable electrode remelting (ESR)and vacuum arc consumable electrode remelting VAR).

FOllowing is chemical compostion of Maraging 250,Maraging C-250 forged steel rings

C Carbon 0.03 max

Si Silicon 0.10 max

Mn Manganese 0.10 max

Ni Nickel 18.50

Co Cobalt 7.50

Mo Molybdenum 4.80

Ti Titanium 0.40

Al Aluminum 0.10

Fe Iron Balance

Following of Maraging 250,Maraging C-250 forging parts heat treatment nechanical property Delivery condition :

UTS, MPa 1,860

0.2% PS, MPa 1,725

Elongation on 4D, % 12

Charpy notch impact, J 20

All our finish production of Maraging 250,Maraging C-250 forged steel material should will done in Following NDE shall be performed in delivery condition:

- Visual inspection

Material verification test

- 100% UT- inspection according to EN 10228-3 (table 3). Depending on the forging geometry,

following inspection types are applicable:

- for 1.4545 forging bar shape components; type 1 (inspection may also be carried out as per EN10308 for type 1)

- for X5CrNiCuNb15-5 forged discs and plate- like components: type 2

- for X5CrNiCuNb155 forging ring or bushing- like components: type 3b and 3

Following is inspection standard of Maraging 250,Maraging C-250 forging material

ASTM E8 Tension Testing of Metallic Materials

ASTM E38 Chemical Analysis of Nickel-Chromium and Nickei-Chromium Iron Alloys

ASTM E112 Estimating the Average Grain Size of Metals

ASTM E139 Coaducting Creep,Creep-Rupture and Stress Rupture Tests oi Metaliic Materials

ASTM A370 mechanical Testing of Steel Products

Welcome your inquiry of Maraging 250,VASCOMAX 250,UNS K92890,Maraging C-250 C250 forging forged steel parts