Description

Jiangsu Liangyi is professional manufacturer of Alloy 24,UNS S34565 open die forging parts and seamless rolled steel forged rings from china

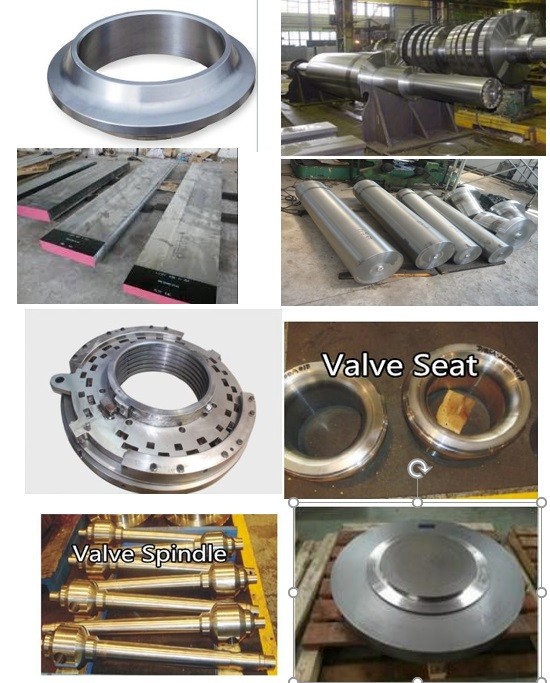

Following is the shape of Alloy 24,UNS S34565 forging steel material that we could do is:UNS S34565 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,UNS S34565 Forged forging steel rings seamless rolled rings,Alloy 24 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,Alloy 24 Forged Forging Steel Discs Disks Blocks plates,UNS S34565 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of Alloy 24,UNS S34565 material that is used in following industry

UNS S34565 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

UNS S34565 forging forged steel turbine rotor shafts

UNS S34565 Forged Forging Steel Butterfly Valve Main Shafts Spindles

Alloy 24 Forged Forging ship boat Marine Propulsion Shafts Propeller Shaft

UNS S34565 Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

Alloy 24 Forged Forging venturi cone meter Body Bodies Blocks

Alloy 24 Forged Forging Steel gate valves Body Bodies bespoke flat bars

UNS S34565 forged steel Flowseal cryogenic High Performance BV Butterfly Valves HPBV shaft

UNS S34565 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

UNS S34565 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

UNS S34565 Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

UNS S34565 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

Alloy 24 Forged Forging forge Steel transition Cone

Alloy 24 Forged Forging Steel Pressure Vessel Reactor Nozzles

UNS S34565 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

Alloy 24 is a nitrogen and molybdenum alloyed austenitic stainless steel, resistant to intergranular corrosion and excellent resistance to pitting, crevice corrosion and stress corrosion cracking in sea water and other corrosive media.

Alloy 24 are widely used in Chemical Process Industry (CPI),Flue gas desulphurisation (FGD) in power plants as well as on large sea going vessels,Seawater desalination and other seawater applications.Food industry,Pharmaceutical industry,Heat exchangers

The stainless steel Alloy 24 forged parts shall be melted by one of the following processes:electric furnace with separate degassing and refining optional or electric furnace followed by electroslag-consumable remelting.

Alloy 24 forged parts will be supplied to this specification that complies with the definitions given in ASTM A788.

UNS S34565 forging material shall be sufficient to develop a wrought structure throughout the part.A forging ratio of 3:1 minimum shall be achieved.

FOllowing is chemical compostion of UNS S34565 forged steel rings

Iron (Fe) 43.2 to 51.6

Chromium (Cr) 23 to 25

Nickel (Ni) 16 to 18

Manganese (Mn) 5.0 to 7.0

Molybdenum (Mo) 4.0 to 5.0

Silicon (Si) 0 to 1.0

Nitrogen (N) 0.4 to 0.6

Niobium (Nb) 0 to 0.1

Carbon (C) 0 to 0.030

Phosphorus (P) 0 to 0.030

Sulfur (S) 0 to 0.010

Following of UNS S34565 forging parts heat treatment mechanical property Delivery condition :

ISO-V charpy 120J (longitudinal))/ 90J (transverse) >10mm material at RT

Elongation Rp0,2 420N/mm² (240N/mm² bei 400°C)

Tensile Rm 800N/mm²

All our Alloy 24,UNS S34565 forging parts can be release en10204-3.1 certificate, or en10204-3.2 inspection certificate from following third party,3.2 mit TUV ,GL (Germanischer Lloyd),BV (Bureau Veritas),DNV (Det Norske Veritas),ABS (American Bureau of Shipping),Lloyds Register of Shipping, RMRS (Russian Maritime Register of Shipping),RINA (Registro Italiano Navale)

For Every pieces of Alloy 24,UNS S34565 forging round bars, we could do following testing Non destructive tests such as visual, dimensional, ultrasonic testing,dye penetrant testing , Magnetic particle test(MPl), the mirrostructure and technological tests such as tensile, resilience, creep tests, hardness,Metallographic exams,Chemical

Welcome your inquiry of Alloy 24,UNS S34565 forging forged steel parts

Following is the shape of Alloy 24,UNS S34565 forging steel material that we could do is:UNS S34565 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,UNS S34565 Forged forging steel rings seamless rolled rings,Alloy 24 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,Alloy 24 Forged Forging Steel Discs Disks Blocks plates,UNS S34565 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of Alloy 24,UNS S34565 material that is used in following industry

UNS S34565 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

UNS S34565 forging forged steel turbine rotor shafts

UNS S34565 Forged Forging Steel Butterfly Valve Main Shafts Spindles

Alloy 24 Forged Forging ship boat Marine Propulsion Shafts Propeller Shaft

UNS S34565 Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

Alloy 24 Forged Forging venturi cone meter Body Bodies Blocks

Alloy 24 Forged Forging Steel gate valves Body Bodies bespoke flat bars

UNS S34565 forged steel Flowseal cryogenic High Performance BV Butterfly Valves HPBV shaft

UNS S34565 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

UNS S34565 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

UNS S34565 Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

UNS S34565 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

Alloy 24 Forged Forging forge Steel transition Cone

Alloy 24 Forged Forging Steel Pressure Vessel Reactor Nozzles

UNS S34565 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

Alloy 24 is a nitrogen and molybdenum alloyed austenitic stainless steel, resistant to intergranular corrosion and excellent resistance to pitting, crevice corrosion and stress corrosion cracking in sea water and other corrosive media.

Alloy 24 are widely used in Chemical Process Industry (CPI),Flue gas desulphurisation (FGD) in power plants as well as on large sea going vessels,Seawater desalination and other seawater applications.Food industry,Pharmaceutical industry,Heat exchangers

The stainless steel Alloy 24 forged parts shall be melted by one of the following processes:electric furnace with separate degassing and refining optional or electric furnace followed by electroslag-consumable remelting.

Alloy 24 forged parts will be supplied to this specification that complies with the definitions given in ASTM A788.

UNS S34565 forging material shall be sufficient to develop a wrought structure throughout the part.A forging ratio of 3:1 minimum shall be achieved.

FOllowing is chemical compostion of UNS S34565 forged steel rings

Iron (Fe) 43.2 to 51.6

Chromium (Cr) 23 to 25

Nickel (Ni) 16 to 18

Manganese (Mn) 5.0 to 7.0

Molybdenum (Mo) 4.0 to 5.0

Silicon (Si) 0 to 1.0

Nitrogen (N) 0.4 to 0.6

Niobium (Nb) 0 to 0.1

Carbon (C) 0 to 0.030

Phosphorus (P) 0 to 0.030

Sulfur (S) 0 to 0.010

Following of UNS S34565 forging parts heat treatment mechanical property Delivery condition :

ISO-V charpy 120J (longitudinal))/ 90J (transverse) >10mm material at RT

Elongation Rp0,2 420N/mm² (240N/mm² bei 400°C)

Tensile Rm 800N/mm²

All our Alloy 24,UNS S34565 forging parts can be release en10204-3.1 certificate, or en10204-3.2 inspection certificate from following third party,3.2 mit TUV ,GL (Germanischer Lloyd),BV (Bureau Veritas),DNV (Det Norske Veritas),ABS (American Bureau of Shipping),Lloyds Register of Shipping, RMRS (Russian Maritime Register of Shipping),RINA (Registro Italiano Navale)

For Every pieces of Alloy 24,UNS S34565 forging round bars, we could do following testing Non destructive tests such as visual, dimensional, ultrasonic testing,dye penetrant testing , Magnetic particle test(MPl), the mirrostructure and technological tests such as tensile, resilience, creep tests, hardness,Metallographic exams,Chemical

Welcome your inquiry of Alloy 24,UNS S34565 forging forged steel parts