Description

Jiangsu Liangyi professional manufacturer of Nimonic ALloy 80A, Nimonic 80A, ALloy 80A,UNS N07080 open die forging parts and seamless rolled steel forged rings from china

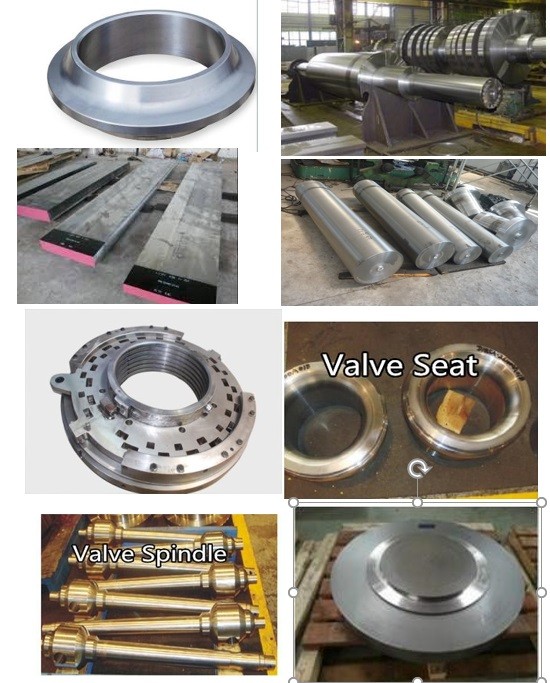

Following is the shape of Nimonic ALloy 80A, Nimonic 80A, ALloy 80A,UNS N07080,nimonic80A forging steel material that we could do is:Nimonic 80A Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Nimonic ALloy 80A Forged forging steel rings seamless rolled rings,Nimonic 80A Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,UNS N07080 Forged Forging Steel Discs Disks Blocks plates,ALloy 80A Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of Nimonic ALloy 80A, Nimonic 80A, ALloy 80A,UNS N07080,nimonic80A material that is used in following industry

Nimonic ALloy 80A Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

Nimonic 80A Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

ALloy 80A Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

UNS N07080 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

ALloy 80A Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

Nimonic 80A Engine exhaust valves and spindles

Nimonic 80A Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

Nimonic 80A Forged Forging Steel power plant steam turbine control reheat valve disc Disk

ALloy 80A Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

ALloy 80A Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

Nimonic 80A forged steel die casting inserts and cores

NIMONIC Alloy 80A is Nickel-Chromium alloy which is precipitation hardenable. It has largely been superseded by Nimonic 90 and Inconel X-750, but because of the low Cobalt content, it is still specified for nuclear applications. Nimonic 80A performs well in applications where high temperature and continuous stress is a significant consideration. Beyond nuclear applications, it is traditionally used in applications such as gas turbines, as well as for exhaust valves in racing engines and spindles and fasteners for the motorsport sector, it is used for gas turbine components (blades, rings and discs), bolts, nuclear boiler tube supports, die casting inserts and cores, and for automobile exhaust valves

Forgings nimonic 80A maeterial shall be manufactured from steel produced by vacuum induction melting 1 electro-slag re-melting {VIM/ESR) or by vacuum induction melting 1 vacuum are re-melting (VIM/VAR) process.

The hot working shall be done in such a way that a uniform fine grained microstructure is achieved.

The NIMONIC 80A forged material shall undergo the following heat treatment:

Solution annealing temperature shall be between 1050 - 1080C for 8 hours followed by air cooling.Stabilization treatment shall be carried out at 850 t 10'C for 24 hours (air cooling) followed by precipitation hardening at 700 t 10'C for 16 hours (air cooling).

The forgings nimonic 80A forged parts shall be free from defects such as cracks, flakes, seams, segregation, non-metallic inclusionsand other defects which may affect the utility of the forgings.

Chemical composition of Nimonic ALloy 80A, Nimonic 80A, ALloy 80A,UNS N07080,nimonic80A forging turbine parts is as Carbon........................................................................0.10 max.

Chromium....................................................................18.0-21.0

Silicon ............................................................................1.0 max

Copper..........................................................................0.2 max.

Iron................................................................................3.0 max.

Manganese ...................................................................1.0 max.

Titanium...........................................................................1.8-2.7

Aluminum ........................................................................1.0-1.8

Cobalt ...........................................................................2.0 max.

Boron ........................................................................0.008 max.

Zirconium....................................................................0.15 max.

Lead........................................................................0.0025 max.

Sulfur ........................................................................0.015 max.

Nickel............................................................................Balance*

mechanical property of for Nimonic ALloy 80A, Nimonic 80A, ALloy 80A,UNS N07080,nimonic80A forged round bars is as follow

0.2% Proof strength (N/mm'):Minimum 600MPA

Tensile Strength(N/mm'):Minimum 1000-1300MPA

Elongation(lo= 5d) (96):Minimum 12%

Reduction In area (%):Minimum 12%

Impact Energy (J)':20J

Hardness in HB:305-405

TEST SAMPLES of finished alloy 80A forged rings

A hardness test shail be performed on all rings at two diametrically opposite positions. At least threehardness indents per position are to be made.

The mechanical properties of nimonic 80A forged rings are to be determined at one forging per melt and heat treatment batch. The specimens are to be taken out of a test sample that has undergone an analogous forming process as the ring. The test sample shall be placed by the rings during the whole heat treatment.

Following NDE shall be performed in delivery condition of nimonic 80A forged turbine blade steel:

100% UT- inspection in simple shaped condition according to EN 10228-4 type 3b and 3c (table 2).100% surface crack inspection in delivery condition according to EN 571-1 or to a similar procedure.

Regarding_ the UT- inspection quality class 3 (table 4) according to EN10228-4 shall be applied. The decision limit for loss of back wall echo is 3 dB and for the real reflector length 10mm.

Defects that will be cut during final machining shall be evaluated individually.

Surface crack inspection - All indications shall be recorded and evaluated individually.

The following details shall be furnished in the test certificate of finished nimonic 80A forged steel:

Heat No. , and melting type.

Dimensional inspection

Details of heat treatment cycle followed.

Results of chemical analysis including tramp elements.

Results of mechanical tests, including hardness test. All individual values shall be reported.Results of ultrasonic tests

Results of surface crack examination

Confirmation of the visual inspection

Confirmation of the verification inspection

Results of additional tests called for in the drawing/order.

Welcome your inquiry of Nimonic ALloy 80A, Nimonic 80A, ALloy 80A,UNS N07080,nimonic80A forging parts