Description

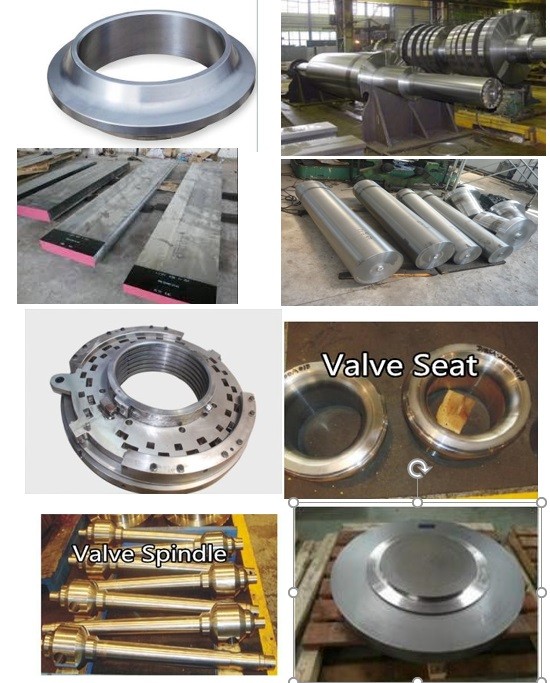

Jiangsu Liangyi professional manufacturer of Waspalloy, AISI 685,UNS N07001 open die forging parts and seamless rolled steel forged rings from china

Following is the shape of Waspalloy, AISI 685,UNS N07001 forging steel material that we could do is:Waspalloy Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Waspalloy Forged forging steel rings seamless rolled rings,Waspalloy Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,UNS N07001 Forged Forging Steel Discs Disks Blocks plates,AISI 685 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of Waspalloy, AISI 685,UNS N07001 material that is used in following industry

Waspalloy Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

Waspalloy Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

AISI 685 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

UNS N07001 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

AISI 685 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

Waspalloy Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

Waspalloy Forged Forging Steel power plant steam turbine control reheat valve disc Disk

AISI 685 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

AISI 685 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

Waspalloy forged material for nuclear power such as :Flow limiter Venturi forgings (steam generator),Forged tubes for pressurizer surge line,reactor nozzles and primary pump fly wheels, divider plates for steam generator,Latch housings, rod travel housings and funnel extension,end ring and rotor stack plate forgings,bearing housings and stator end cap and closure ring forgings,Containment plates, rings and closure heads,Waste Flasks and Mounting Skirt,RPV Upper Shell and HSG Shell,Shell Strakes and Transition Cones,Pressure Components,Lifting Pin Tools and Trunnions,Pressuriser Upper Head and Upper Shell,Steam Drumhead and Lifting Pintles

Waspalloy is a nickel based age hardenable alloy that possesses high temperature strength while still having a good corrosion resistance, especially to oxidation. WASPALOY can be used at temperatures up to 650°C (1200°F) which is critical rotating applications. WASPALOY is used in gas turbine engine components, missile systems, shafts, spacers, seals, rings, casings, fasteners and many other uses in engine hardware, airframe assemblies.

The production standard of The Waspalloy forged material is as follows:

ASTM B 637, ISO 9723, ISO 9724, ISO 9725, AMS 5704, AMS 5706, AMS 5707, AMS 5708, AMS 5709, AMS 5828, MAM 5706, AECMA PrEN 2193, AECMA PrEN 2194, AECMA PrEN 2406, AECMA PrEN 2958, AECMA PrEN 2959, AECMA PrEN 2960, AECMA PrEN 3220

The Waspalloy forged parts shall be free from defects such as cracks, flakes, seams, segregation, non-metallic inclusionsand other defects which may affect the utility of the forgings.

Waspalloy forgeed parts shall be produced by multiple melting using consumable electrode practice in the remelt cycle or shall be induction melted under vacuum,unless otherwise permitted by purchaser.

FOllowing is inspection standard of Waspalloy Forgd parts

AMS 2261 -Tolerances,Nickel,Nickel Base,and Cobalt Base Alloy Bars and Forging Stock AMS 2269 -Chemical Check Analysis Limits,Wrought Nickel Alloys and Cobalt Alloys

AMS 2350 -Standards and Test Methods

AMS 2371 -Quality Assurance Sampling of Corrosion and Heat Resistant Steels and Alloys Wrought Products Except Forgings and Forging Stock

AMS 2374 -Quality Assurance Sampling of Corrosion and Heat Resistant Steels and Alloys Forgings and Forging Stock

AMS 2375 -Control of Forgings Requiring First Article Approval

AMS 2806-Identification,Bars,Wire,Mechanical Tubing,and Extrusions,Carbon and Alloy Steels and Heat and Corrosion Resistant Steels and Alloys

AMS 2808-Identification,Forgings

AMS 7490 -Rings,Flash Welded,Corrosion and Heat Resistant,Austenitic Steels and Austenitic-Type Alloys

ASTM E8 - Tension Testing of Metallic Materials

ASTM E10 - Brinell Hardness of Metallic Materials

ASTM E112 - Estimating the Average Grain Size of Metals

ASTM E139 - Conducting Creep,Creep-Rupture,and Stress-Rupture Tests of Metallic Materials

ASTM E292 - Conducting Time-For-Rupture Notch Tension Tests of Materials

ASTM E354 - Chemical Analysis of High-Temperature,Electrical,Magnetic,and Other Similar Iron,Nickel,and Cobalt Alloys

Chemical compostion of Waspalloy forged parts

| min max | ||||||||||||||||||||

| Carbon | 0.02 - 0.10 | |||||||||||||||||||

| Manganese | 0.10 | |||||||||||||||||||

| Silicon | 0.15 | |||||||||||||||||||

| Phosphorus | 0.015 | |||||||||||||||||||

| Sulphur | 0.015 | |||||||||||||||||||

| Chromium | 18.00 - 21.00 | |||||||||||||||||||

| Cobalt | 12.00 - 15.00 | |||||||||||||||||||

| Molybdenum | 3.50 - 5.00 | |||||||||||||||||||

| Titanium | 2.75 - 3.25 | |||||||||||||||||||

| Aluminum | 1.20 - 1.60 | |||||||||||||||||||

| Zirconium | 0.02 - 0.08 | |||||||||||||||||||

| Boron | 0.003- 0.010 | |||||||||||||||||||

| Iron | 2.00 | |||||||||||||||||||

| Copper | 0.10 | |||||||||||||||||||

| Nickel | remainder | |||||||||||||||||||

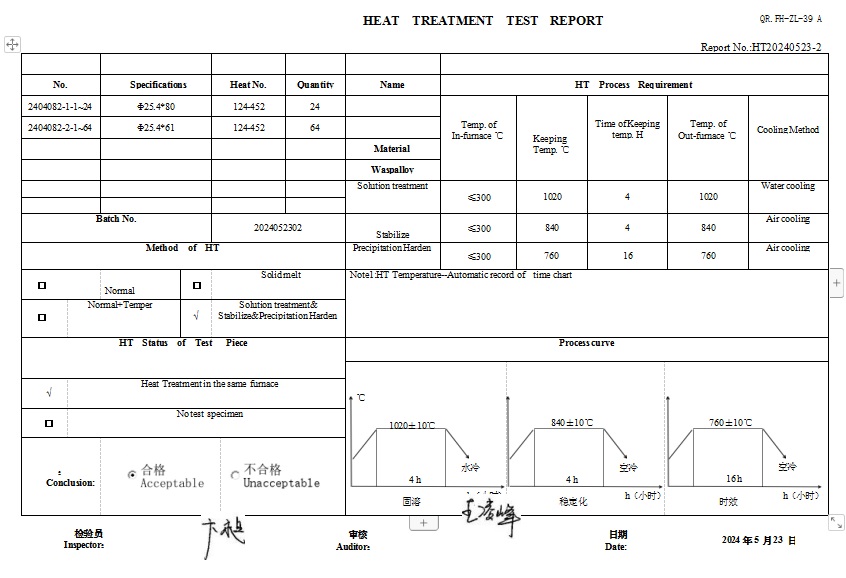

Stabilization Heat Treatment: Heat to 1550°F±15°(845℃±89,hold at heat for 4 hr±0.5,and cool in air.

Precipitation Heat Treatment:Heat to 1400°F±15°(760°C±8²),hold at heat for 16 hr±1,and cool in air.

Properties:The product shall conform to the following requirements:

Tensile Properties of Waspalloy forged bars:Shall be as follows on product 3.25 in.(82.5 mm)and under in nominal cross-section dimension,determined in accordance with ASTM E8.Tensile property requirements for product over 3.25 (82.5 mm)in nominal cross-section dimension shall be as agreed upon by purchaser and vendor.

Tensile Strength,min 160,000 psi (1103 MPa)

Yield Strength at 0.2%Offset,min 110,000 psi(758 MPa)

Elongation in 2 in.(50 mm)or 4D,min 15%

Reduction of Area,min 18%

Tensile property requirements of apply to both the longitudinal and transverse directions except that transverse tests are not required on product from which a test speci-men not less than 2.50 in.(63.5 mm)in length can be obtained.Specific orientation and location of specimens from Waspalloy forgings rings shall be as agreed upon by purchaser and vendor.Longitudinal tensile properties need not be determined on product tested in the transverse direction,unless otherwise specified by purchaser.

Hardness:Should be 321-403 HB or equivalent,determined in accordance with ASTM E10,but the product shall not be rejected on the basis of hardness if the tensile property requirements are met.

Stress-Rupture Properties of Waspalloy forged parts :Shall be as follows;testing of notched specimens and of combination smooth-and-notched specimens shall be performed in accordance with ASTM E292 and of smooth specimens in accordance with ASTM E139:

At 1350°F(732°C):A combination smooth-and-notched test specimen machined to the dimensions shown in Fig.1 and Table I,maintained at 1350°F±3(732°C±2°)while a load sufficient to produce an initial axial stress of 75,000 psi(517 MPa)is applied continuously,shall not rupture in less than 23 hours.The test shall be continued to rupture without change of load.After the 23 hr,if rupture occurs in the notch,the smooth section shall,by suitable means,be continued to rupture or a separate smooth specimen shall be tested to rupture in not less than 23 hours. Elongation of the smooth section after rupture,measured at room temperature,shall be not less than 8%in 4D.

As an alternate procedure,separate smooth and notched specimens,machined from adjacent sections of the same piece,with gage sections conforming to the respective dimensions of Table I may be tested individually under the above conditions.The smooth specimen shall not rupture in less 23 hr and elongation after rupture,measured at room temperature,shall be not less than 8%in 4D.The notched specimen shall not rupture in less than 23 hr but need not be tested to rupture.

The tests may be conducted using a load higher than required to produce an initial axial stress of 75,000 psi(517 MPa)but load shall not be changed while test is in progress.Time to rupture,rupture location,and elongation requirements shall be as specified

When permitted by purchaser,the tests may be conducted using incremental loading.In such case,the load required to produce an initial axial stress of 75,000 psi(517 MPa)shall be used to rupture or for 23 hr,whichever occurs first.After the 23 hr and at intervals of 8-16 hr,preferably 8-10 hr,thereafter,the stress shall be increased in increments of 5000 psi(34.5 MPa).Time to rupture,rupture location,and elongation requirements shall be as specified

At 1500°F(815°C):A tensile specimen,maintained at 1500°F±3°(815³C±2°)while a load sufficient to produce an initial axial stress of 40,000 psi (276 MPa)is applied continuously,shall not rupture in less than 23 hours.The test shall be continued to rupture without chauge of load.Elongation after rupture,measured at room temperature,shall be not less than 5%in 4D.

The test of may be conducted using a load higher than required to produce an initial axial stress of 40,000 psi (276 MPa)but load shall not be changed while test is in progress,Time to rupture and elongation requirements shall be as specified

When permitted by purchaser,the test muy be conducted using incremental loading.In such case,the load required to produce an axial stress of 40,000 psi (276 MPa) shall be used to rupture or for 23 hr,whichever occurs first.After the 23 hr and at intervals of 8-16 hr,preferably 8-10 hr,thereafter,the stress shall be increased in increments of 5000 psi(34.5 MPa).Time to rupture and elongation requirements shall be as specified

Grain Size of Waspalloy forged rings :Shall be predominately 3 or finer with occasional grains as large as 1 permissible, determined by comparison of a polished and etched specimen with the chart in ASTM E¹12.

Following is heat treatment report of waspalloy forged bars

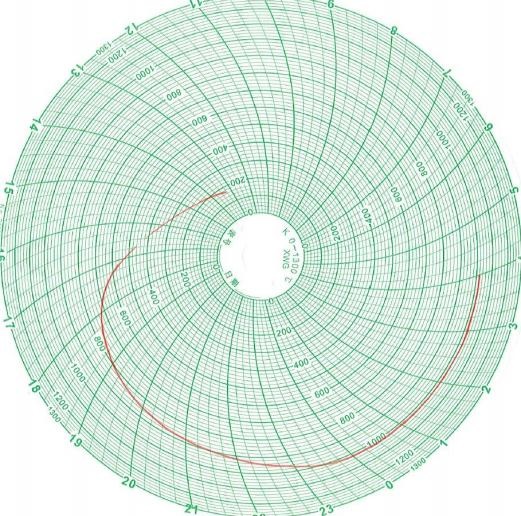

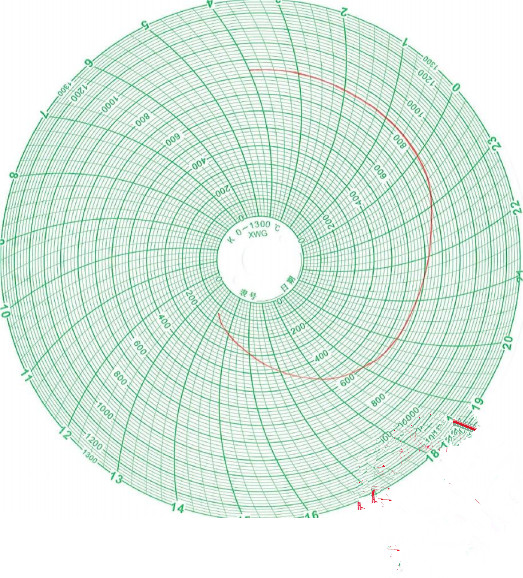

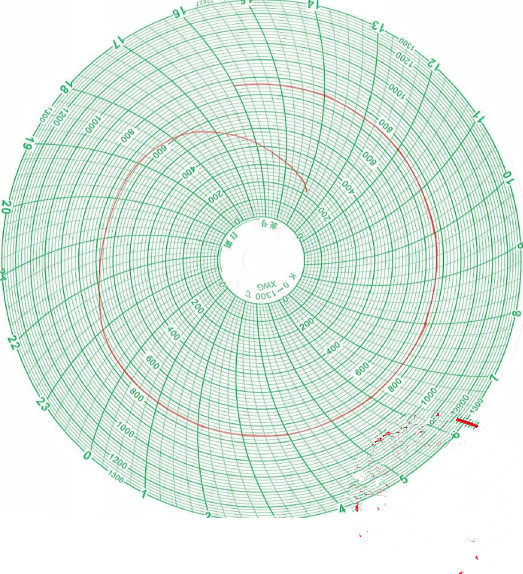

FOllowing is hear treatment chart of waspalloy forged bars

Welcome your inquiry of Waspalloy,AISI 685,UNS N07001 forging parts