Description

Jiangsu Liangyi professional manufacturer of 1.4532(1.4574,X8CrNiMoAl15-7-2,X 8 CrNiMoAl 15-7-2,X8CrNiMoAl1572,X8CrNiMoAl15.7.2)open die forging parts and seamless rolled steel forged rings from china

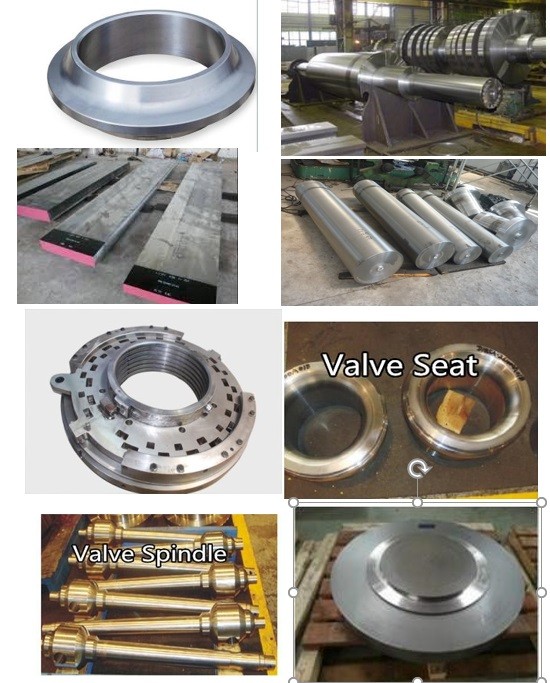

Following is the shape of 1.4532(1.4574,X8CrNiMoAl15-7-2,X 8 CrNiMoAl 15-7-2,X8CrNiMoAl1572,X8CrNiMoAl15.7.2) forging steel material that we could do is:1.4532 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,X 8 CrNiMoAl 15-7-2,Forged forging steel rings seamless rolled rings,X8CrNiMoAl15-7-2 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,X8CrNiMoAl1572 Forged Forging Steel Discs Disks Blocks plates,X8CrNiMoAl15.7.2 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 1.4532(1.4574,X8CrNiMoAl15-7-2,X 8 CrNiMoAl 15-7-2,X8CrNiMoAl1572,X8CrNiMoAl15.7.2) material that is used in following industry

1.4532 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

X8CrNiMoAl15-7-2 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

X8CrNiMoAl15.7.2 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

1.4574 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

1.4532 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

X8CrNiMoAl1572 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate pump

X8CrNiMoAl15.7.2Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

X8CrNiMoAl1572 Forged Forging Marine Ship Boat Propeller Shafts

1.4532 Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

1.4532 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

X8CrNiMoAl15.7.2 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

1.4574Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings

1.4532(1.4574,X8CrNiMoAl15-7-2) is a precipitation hardenening stainless steel used for applications requiring high strength and moderate corrosion resistance. It is similar to 17-7 with the substitution of 2% Molybdenum for 2% Chromium resulting in higher room and elevated temperature strength for 1.4532. X8CrNiMoAl15-7-2 stainless steel may be formed in a soft austenitic condition and then hardened to high strength levels by low temperature heat treatments. This allows miminum distortion compared to other quench and temper hardening processes. For maximum strength requirements,

1.4532(1.4574,X8CrNiMoAl15-7-2) forged Steel is used for valve parts, tanks, CNC parts and tooling in aerospace industry. Resistant to acids and chlorides commonly occuring in river water. Sufficiently resistant to ammonia and nitrogen tetroxide in mild temperature. Rust may occure in a marine atmosphere.The steel has better stress corrosion cracking resistance and resistance to reducing acids and chloride containing pleas than 1.4568 steel. It also has limited resistance to crevice corrosion and pitting.

FOllowing is chemical compostion of 1.4532(1.4574,X8CrNiMoAl15-7-2) forged steel sleeves

Iron, Fe 69.58 – 76.75

Chromium, Cr 14.0 – 16.0

Nickel, Ni 6.5 – 7.75

Molybdemum, Mo 2.0 – 3.0

Manganese, Mn ≤ 1.0

Silicon, Si ≤ 1.0

Aluminum, Al 0.75 – 1.5

Carbon, C ≤ 0.09

Sulfur, S 0.04

Phosphorus, P ≤ 0.04

Following of 1.4532(1.4574,X8CrNiMoAl15-7-2) forging parts mechnical property :

Properties Metric English

Hardness, Rockwell B 88 88

Tensile Strength, Ultimate 896 MPa 130000 psi

Tensile Strength, Yield 372 MPa 54000 psi

Elongation at Break 35% 35%

Modulus of Elasticity 200 GPa 29000 ksi

Elastic Modulus 190 – 210 GPa 27557 – 30458 ksi

Poisson’s Ratio 0.27 – 0.30 0.27 – 0.30

Heat Treatment 1.4532(1.4574,X8CrNiMoAl15-7-2) forging material is as follows

1) austenite conditioning, 2) cooling to transform the austenite to martensite and 3) precipitation hardening.

The material normally is supplied from the mill in Condition A. After fabrication, an austenite conditioning treatment is followed by a transformation treatment to either Condition T or Condition R100. Then the material is precipitation hardened to either Condition TH 1050 or Condition RH 950 to develop fully useable properties.

To obtain the highest mechanical properties in this alloy, Condition A is transformed to martensite at the mill by cold reduction to Condition C. After fabrication by the user, hardening to Condition CH 900 is accomplished with a single low temperature heat treatment.

FOllowing is testing standard of our 1.4532(1.4574,X8CrNiMoAl15-7-2) forged steel parts

ASTM E10-12: Standard Test Method for Brinell hardness of Metallic Materials;

ASTM A370-12: Standard Test Methods and Definitions for Mechanical Testing of Steel Products;

ASTM E23-07a: Standard Test Methods for Notched Bar Impact Testing of Metallic Materials;

AMS 2315G: Determination of Delta Ferrite Content,

ASTM E45-05: Standard Test Methods for Determining the Inclusion Content of Steel,

ASTM E112-10: Standard Test Methods for Determining Average Grain Size,

ASTM E837: Standard Test Method for Determining Residual Stresses by the Hole-Drilling Strain-Gage Meth

Welcome your inquiry of 1.4532(1.4574,X8CrNiMoAl15-7-2) forging forged steel parts