Description

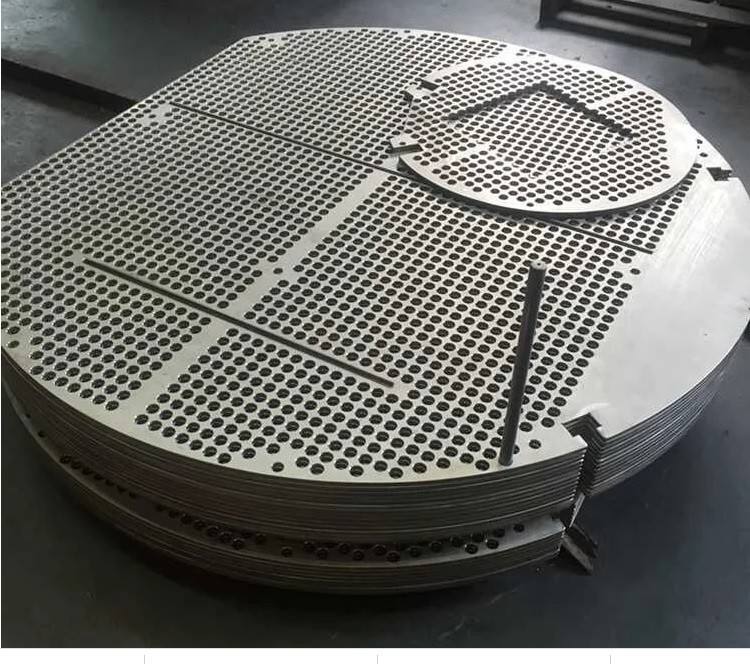

We are professional baffle plates for heat exchangers Manufacture from china, the maximum diameter of baffle plates that we could produce is up to 4000MM diameter, The maximum thickness of baffle plates that we could produce is up to 800MM

Baffles are components of shell and tube heat exchangers which are used to support and fix the tubes in a defined position. There are different types of baffle configurations. The most popular type is the perforated plate in the form of a segmented circle. The segmental baffles are arranged so that the segmented section faces are disposed opposite to each other along a bundle of tubes at specified interval. No Tube in Window (NTIW) baffles, Helically-shaped baffles, full support baffle are other types that can be fabricated in our company.

Also we could produce Composite baffle plates : Composite Explosion baffle plates , Cladding baffle plates , cladded baffle plates ,Overlay Welding with weld overlay with duplex, titanium and nickel alloys for baffle plates

baffle plates is widely used in Shell and tube heat exchangers in forms of Stationary Tube Sheet and Floating Tube Sheets, boilers,Evaporator,Nuclear Power, pressure vessels, steam turbines, large central air-conditioning industry. Mainly used on chemical containers, such as column-tube heat exchangers, pressures vessels, boilers, condensers, central air conditioning, evaporator, desalination,

We could final machine baffle plates as per drawing of clients,including: Drilling, Lathe, Milling, Machining, Pull Groove Machining, Reaming and so on.

In order to delivery quality of baffle plates ,our workshop have following inspection equipment,Mechanical Property Testing Equipment,Chemical Compostion Testing Equipment,Hardness Tester,Dye Penetration Testing Equipment,Corrosion tester,Clad Strength Tester,Ultrasonic flaw detector,Gauges, Roughness tester, groove gauge, Calipers etc.

Hole Size Range Of baffle plates that we could priduce: Φ1-Φ300

Hole Finish Accuracy Of baffle plates that we could produce : Positioning Precision Max0.01mm, hole diameter Min Tolerance 0.01mm

Roughness Of baffle plates that we could produce is : Ra0.6

Following is material grade of baffle plates that we could supply:

Carbon steel (A105, A266 CL2/CL4)

Plate material of Baffle plate: A36, SS440, A516 Gr60/70

Low Temp Carbon steel (A350 LF2 CL1/CL2, LF3)

High Yield Carbon steel (A694 F52/F60/F65/F70)

Stainless steel (A182 F304/L, F304H, F310, F316/L, F317/L, F321/H, F347/H, F44)

Low alloy steel (A182 F1, F5, F9, F11 CL1/CL2/CL3, F12 CL1/CL2, F22 CL1/CL3, F23, F91, F92)

Duplex stainless steel ( A182 F51, F53, F60)

Alloy steel (Alloy 20, Alloy625/825/800)

• Alloy 20 UNS No. 08020 –

• Nickel 200 UNS No. 02200 Wnr 2.4066

• Nickel 201 UNS No. 02201 Wnr 2.4068

• Alloy 400 UNS No. 04400 Wnr 2.4360

• Alloy C276 UNS No. 10276 Wnr 2.4819

• Alloy B2 UNS No. 10665 Wnr 2.4617

• Alloy C4 UNS No. 06455 Wnr 2.4610

• Alloy G30 UNS No. 06030 –

• Alloy 600 UNS No. 06600 Wnr 2.4816

• Alloy 625 UNS No. 00625 Wnr 2.4856

• Alloy 800 UNS No. 08800 Wnr 1.4876

• Alloy 800H UNS No. 08810 Wnr 1.4958

• Alloy 800HT UNS No. 08811 Wnr 1.4959

• Alloy 825 UNS No. 08825 Wnr 2.4858

All our finished Baffle plates will have following testing

Mechanical Analysis

Universal Tensile Testing

Brinell and Rockwell Hardness Testing

Impact test

Microscope for microstructure analysis of raw material.

Corrosion Test- (IGC Test)

Non Destructive Tests

Liquid Penetrant Testing (PT)

Magnetic Particle Testing (MT)

UT(ultrasonic testing)

Portable hardness test

Dye Penetration Test (DP)

Size inspection