Description

Jiangsu Liangyi professional manufacturer of 1.7335,13CrMo4-5,13CrMo45,13CrMo4.5 open die forging parts and seamless rolled steel forged rings from china

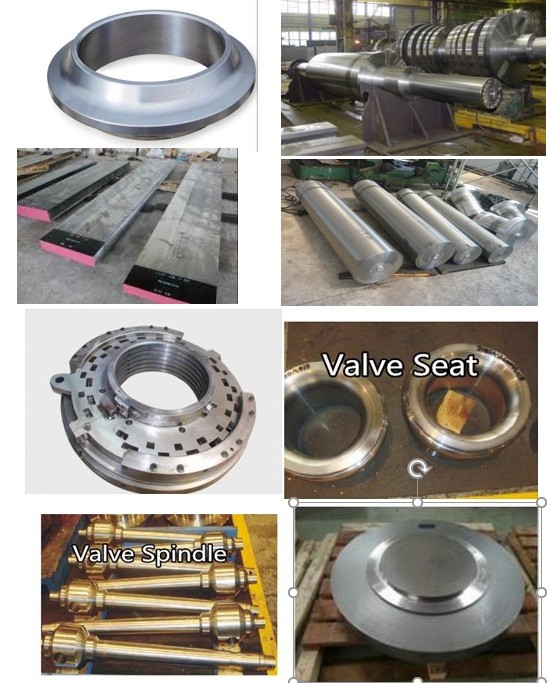

Following is the shape of 1.7335,13CrMo4-5,13CrMo45,13CrMo4.5 forging steel material that we could do is: 1.7335 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,13CrMo4-5 Forged forging steel rings seamless rolled rings,13CrMo4.5 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,1.7335 Forged Forging Steel Discs Disks Blocks plates,13CrMo45 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 1.7335,13CrMo4-5,13CrMo45,13CrMo4.5 material that is used in following industry

1.7335 Forged Forging Swivel Ring Flanges

13CrMo4-5 Forging/Forged Forge Steel Wye Piece/Piggable Wyes

13CrMo4-5 Forged Forging Swept branches outlets steel fittings swept saddles

13CrMo4-5 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

13CrMo45 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate pump

13CrMo45 Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

1.7335 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings

13CrMo4.5 Forged Forging forge Steel transition Cone

1.7335 Forged Forging Blowout Preventer RAM Annular dual Bops Body Bodies Block

1.7335 is characterised by good weldability. These types of steel are used above all for manufacturing boilers, pressure vessels and pipes for the transportation of hot liquids. They also offer good properties at high and low temperatures. The product is always supplied in the normalised and tempered condition.

FOllowing is production standard of 1.7335 forged steel material, :

EN 10028-2: 2009 Flat products made of steels for pressure purposes. Non-alloy and alloy steels with specified elevated temperature properties

EN 10222-2: 2000 Steel forgings for pressure purposes. Ferritic and martensitic steels with specified elevated temperature properties

EN 10216-2: 2014 Seamless steel tubes for pressure purposes. Technical delivery conditions. Non-alloy and alloy steel tubes with specified elevated temperature properties

EN 10253-2: 2007 Butt-welding pipe fittings. Non alloy and ferritic alloy steels with specific inspection requirements

EN 10273: 2007 Hot rolled weldable steel bars for pressure purposes with specified elevated temperature properties

For melting 13CrMo4-5 forging steel material, we have following melting equipment

60 t Electric Arc Furnace (EAF) / Power 40 MVA

2 Ladle Furnace (LF)

2 Tank Degassing VD - VOD type

Pits for bottom pouring

ESR Plant (max weight 32 t)

FOllowing is chemical compostion of 1.7335, 13CrMo4-5,13CrMo4-5, 13CrMo45 forged steel rings

C 0.08 - 0.18

Si max 0.35

Mn 0.4 - 1

P max 0.025

S max 0.01

Cr 0.7 - 1.15

Mo 0.4 - 0.6

N max 0.012

Cu max 0.3

Following of 1.7335 forging parts mechanical property :

Nom. thick. e Yield strength ReH

≤16 mm ≥ 300 MPa

>16 mm ≥ 290 MPa

Nom. thick. e Tensile stength Rm

≤ 25 mm 450 – 600 MPa

Nom. thick. e Total elongation A5

3< e ≤ 25 mm ≥ 19 %

Yield point at elevated temperature

Test Yield point at elev. temp. Rp0,2

temperature e ≤ 16 mm e > 16 mm

50°C ≥ 294 MPa ≥ 285 MPa

100°C ≥ 285 MPa ≥ 275 MPa

150°C ≥ 269 MPa ≥ 260 MPa

200°C ≥ 252 MPa ≥ 243 MPa

250°C ≥ 234 MPa ≥ 226 MPa

300°C ≥ 216 MPa ≥ 209 MPa

350°C ≥ 200 MPa ≥ 194 MPa

400°C ≥ 186 MPa ≥ 180 MPa

450°C ≥ 175 MPa ≥ 169 MPa

500°C ≥ 164 MPa ≥ 159 MPa

Heat treatment wat of 1.7335 forged parts is as following

Softening annealing at the temperature of 600 - 700℃

Normalizing with cooling in calm air at the temperature of 910 - 940℃

Relief annealing with calm air cooling at the temperatures of 660 - 710℃

Hardening with cooling in water at the temperature of 890 - 910 ℃,

when cooling in oil - 900 - 930 ℃ Tempering in calm air at temperatures of 650 - 720 °C

FOllowing is inspection standard of 1.7335 Forged steel material

ASTM E 8 Tension Testing of Metallic Materials

ASTM E 8M Tension Testing of Metallic Materials (Metric)

ASTM E 10 Brinell Hardness of Metallic Materials

ASTME 139 Conducting Creep, Creep-Rupture, and Stress-Rupture Tests of Metallic Materials

ASTM E 292 Conducting Time-for-Rupture Notch Tension Tests of Materials

The following result will be reported to clients along with the supply of finished 1.7335 forged parts . On all the reports the heat number, forge serial number, order number and material designation shall be marked.

· Heat number and heat analysis including trace elements and melting process.

· Weight of ingot stating L/D ratio.

· Degree of forging reduction (Amax/Afinal at greatest body dia)

· Percentage of top and bottom discards.

· Heat treatment temperature actually measured, holding times, method of cooling and cooling conditions (cooling rates) including all reheat treatments are to be quoted as a complete temperature time sequence.

· Results of residual stress measurement if performed.

· Results of Ultrasonic examination giving details of probe type and size, frequency, sensitivity, sketch showing the areas covered etc.

· Results of Magnetic Particle Inspection.

· Hardness variation throughout the surface depicting the locations.

· Results of Metallographic test along with photo-micrographs.

Welcome your inquiry of 1.7335, 13CrMo4-5,13CrMo4-5, 13CrMo45 forging forged steel parts