Description

Jiangsu Liangyi is professional manufacturer of 1.4404,X2CrNiMo17-12-2,X2CrNiMo17122,X2CrNiMo17.12.2 open die forging parts and seamless rolled steel forged rings from china

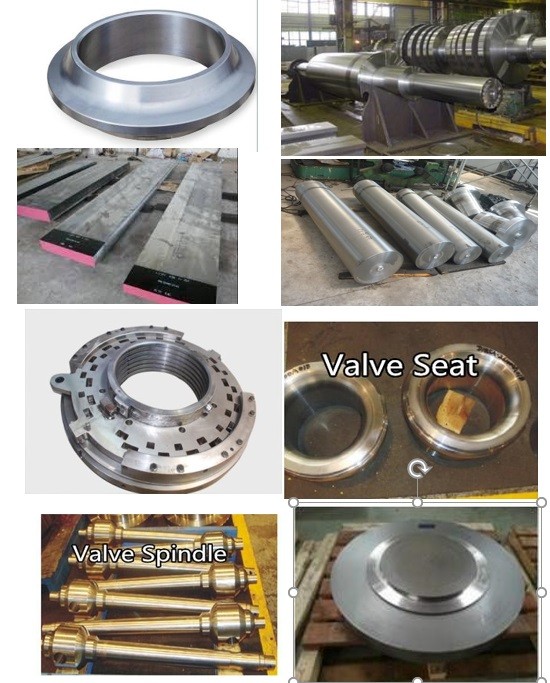

Following is the shape of 1.4404,X2CrNiMo17-12-2,X2CrNiMo17122,X2CrNiMo17.12.2 forging steel material that we could do is:X2CrNiMo17-12-2 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,X2CrNiMo17.12.2 Forged forging steel rings seamless rolled rings,1.4404 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,1.4404 Forged Forging Steel Discs Disks Blocks plates,X2CrNiMo17-12-2 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 1.4404,X2CrNiMo17-12-2,X2CrNiMo17122,X2CrNiMo17.12.2 material that is used in following industry

X2CrNiMo17-12-2 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

X2CrNiMo17.12.2 Forged Forging Steel Butterfly Valve Main Shafts Spindles

1.4404 Forged Forging Swept branches outlets steel fittings swept saddles

X2CrNiMo17-12-2 Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

X2CrNiMo17.12.2 Forged Forging Steels Christmas Trees wellhead Spool Body Bodies cylinder

1.4404 Forged Forging venturi cone meter Body Bodies Blocks

1.4404 Forged Forging Steel gate valves Body Bodies bespoke flat bars

X2CrNiMo17-12-2 forged steel Flowseal cryogenic High Performance BV Butterfly Valves HPBV shaft

X2CrNiMo17-12-2 forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

X2CrNiMo17.12.2 Forged Forging Steel double studded adapter flange

X2CrNiMo17.12.2 Forged Forging Steel integral Mud Flange Flanged outlet Studded crosses

1.4404 Forged Forging Steel Casing Heads,Tubing Heads,Casing Hangers,Tubing Hangers,Tubing Spools,Casing Spools,Spacer Spools

X2CrNiMo17.12.2 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

X2CrNiMo17.12.2 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

X2CrNiMo17.12.2 Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

X2CrNiMo17.12.2 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

1.4404 Forged Forging forge Steel transition Cone

1.4404 Forged Forging Steel Pressure Vessel Reactor Nozzles

X2CrNiMo17-12-2 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

1.4404 is 1.4404 is a low-carbon, austenitic chromium-nickel-molybdenum steel. Due to the addition of 2 - 2.5% molybdenum, the corrosion resistance of the 1.4404 is significantly better than that of the standard austenitic grades 1.4301 and 1.4307.

It is widely used in Construction encasement, doors, windows and armatures, offshore modules, cisterns and pipes for chemical tankers, production, warehousing and overland transportation of chemicals, food and beverages, pharmacy, synthetic fibre, paper and textile plants and pressure vessels

Our X2CrNiMo17.12.2 forged steel raw material is normal melting by Basic Electric Furnace (EAF, AOD, VOD) or + Electroslag remelting. (ESR) AS PER CLIENTS NEEDS

FOllowing is chemical compostion of X2CrNiMo17.12.2 forged steel rings

Carbon (C) 0.03

Silicon (Si) 1.00

Manganese (Mn) 2.00

Phosphorous (P) 0.045

Sulfur (S) 0.0151)

Chromium (Cr) 16.50 - 18.50

Nickel (Ni) 10.00 - 13.00

Nitrogen (N) 0.10

Molybdenum (Mo) 2.00 - 2.50

Iron (Fe) Balance

Heat treatment of 1.4404 forged material is as follows

Optimal material properties are realised after solution annealing in the temperature range 1000 °C –1100 °C followed by rapid cooling in air or water. During operation and fabrication, the time spent in the temperature range 450 °C – 850 °C must be minimised to avoid embrittlement. In the solution annealed condition, the following mechanical properties may be attained:

Following of X2CrNiMo17-12-2 forging parts heat treatment mechanical property Delivery condition :

Tensile strength, Rm 500 - 700 MPa

Yield strength, Re: >200 MPa

Hardness, HB: <215 Elongation,

A: >30%

Impact strength, KV: >60J

In order to make forging and make heat treatment 1.4404,X2CrNiMo17-12-2 forging steel parts, we have following production equipment

Forging Process:3200/4200/6000 t Open die presses

Manipulators, Lifting Capacity up to 60 t

Heating Forging Furnaces, Max Capacity 150 t

Furnaces for Hydrogen Bake-Out Up to 14 m

Heat Treatment Semi-automatic Heat Treatment System Quality Heat Treatment

Furnaces Max lenght 18 m Quenching tanks up to 16 m

Following is inspection standard of 1.4404,X2CrNiMo17-12-2 forging material

ASTM E8 Tension Testing of Metallic Materials

ASTM E38 Chemical Analysis of Nickel-Chromium and Nickei-Chromium Iron Alloys

ASTM E112 Estimating the Average Grain Size of Metals

ASTM E139 Coaducting Creep,Creep-Rupture and Stress Rupture Tests oi Metaliic Materials

ASTM A370 mechanical Testing of Steel Products

The following requirements of 1.4404,X2CrNiMo17-12-2 forged parts are acceptance tests and shall be performed on each heat or lot as applicable.

Composition of each heat.

Hardness and average grain size of each lot of bars, forgings, and forged rings as solution heat treated.

Room-temperature tensile properties , hardness , and stress-rupture properties (of each lot of bars, forgings, and forged rings after precipitation heat

treatment.

Microstructure of each lot.

Periodic Tests: The following requirements are periodic tests and shall be performed at a frequency selected by the vendor unless frequency of testing is specified by purchaser:

Tensile Properties

hardness and stress-rupture properties of 1.4404 forged parts after resolution and precipitation heat treatment

Grain flow of X2CrNiMo17-12-2 forgings

Welcome your inquiry of 1.4404,X2CrNiMo17-12-2,X2CrNiMo17122,X2CrNiMo17.12.2 forging forged steel parts

Following is the shape of 1.4404,X2CrNiMo17-12-2,X2CrNiMo17122,X2CrNiMo17.12.2 forging steel material that we could do is:X2CrNiMo17-12-2 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,X2CrNiMo17.12.2 Forged forging steel rings seamless rolled rings,1.4404 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,1.4404 Forged Forging Steel Discs Disks Blocks plates,X2CrNiMo17-12-2 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 1.4404,X2CrNiMo17-12-2,X2CrNiMo17122,X2CrNiMo17.12.2 material that is used in following industry

X2CrNiMo17-12-2 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

X2CrNiMo17.12.2 Forged Forging Steel Butterfly Valve Main Shafts Spindles

1.4404 Forged Forging Swept branches outlets steel fittings swept saddles

X2CrNiMo17-12-2 Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

X2CrNiMo17.12.2 Forged Forging Steels Christmas Trees wellhead Spool Body Bodies cylinder

1.4404 Forged Forging venturi cone meter Body Bodies Blocks

1.4404 Forged Forging Steel gate valves Body Bodies bespoke flat bars

X2CrNiMo17-12-2 forged steel Flowseal cryogenic High Performance BV Butterfly Valves HPBV shaft

X2CrNiMo17-12-2 forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

X2CrNiMo17.12.2 Forged Forging Steel double studded adapter flange

X2CrNiMo17.12.2 Forged Forging Steel integral Mud Flange Flanged outlet Studded crosses

1.4404 Forged Forging Steel Casing Heads,Tubing Heads,Casing Hangers,Tubing Hangers,Tubing Spools,Casing Spools,Spacer Spools

X2CrNiMo17.12.2 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

X2CrNiMo17.12.2 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

X2CrNiMo17.12.2 Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

X2CrNiMo17.12.2 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

1.4404 Forged Forging forge Steel transition Cone

1.4404 Forged Forging Steel Pressure Vessel Reactor Nozzles

X2CrNiMo17-12-2 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

1.4404 is 1.4404 is a low-carbon, austenitic chromium-nickel-molybdenum steel. Due to the addition of 2 - 2.5% molybdenum, the corrosion resistance of the 1.4404 is significantly better than that of the standard austenitic grades 1.4301 and 1.4307.

It is widely used in Construction encasement, doors, windows and armatures, offshore modules, cisterns and pipes for chemical tankers, production, warehousing and overland transportation of chemicals, food and beverages, pharmacy, synthetic fibre, paper and textile plants and pressure vessels

Our X2CrNiMo17.12.2 forged steel raw material is normal melting by Basic Electric Furnace (EAF, AOD, VOD) or + Electroslag remelting. (ESR) AS PER CLIENTS NEEDS

FOllowing is chemical compostion of X2CrNiMo17.12.2 forged steel rings

Carbon (C) 0.03

Silicon (Si) 1.00

Manganese (Mn) 2.00

Phosphorous (P) 0.045

Sulfur (S) 0.0151)

Chromium (Cr) 16.50 - 18.50

Nickel (Ni) 10.00 - 13.00

Nitrogen (N) 0.10

Molybdenum (Mo) 2.00 - 2.50

Iron (Fe) Balance

Heat treatment of 1.4404 forged material is as follows

Optimal material properties are realised after solution annealing in the temperature range 1000 °C –1100 °C followed by rapid cooling in air or water. During operation and fabrication, the time spent in the temperature range 450 °C – 850 °C must be minimised to avoid embrittlement. In the solution annealed condition, the following mechanical properties may be attained:

Following of X2CrNiMo17-12-2 forging parts heat treatment mechanical property Delivery condition :

Tensile strength, Rm 500 - 700 MPa

Yield strength, Re: >200 MPa

Hardness, HB: <215 Elongation,

A: >30%

Impact strength, KV: >60J

In order to make forging and make heat treatment 1.4404,X2CrNiMo17-12-2 forging steel parts, we have following production equipment

Forging Process:3200/4200/6000 t Open die presses

Manipulators, Lifting Capacity up to 60 t

Heating Forging Furnaces, Max Capacity 150 t

Furnaces for Hydrogen Bake-Out Up to 14 m

Heat Treatment Semi-automatic Heat Treatment System Quality Heat Treatment

Furnaces Max lenght 18 m Quenching tanks up to 16 m

Following is inspection standard of 1.4404,X2CrNiMo17-12-2 forging material

ASTM E8 Tension Testing of Metallic Materials

ASTM E38 Chemical Analysis of Nickel-Chromium and Nickei-Chromium Iron Alloys

ASTM E112 Estimating the Average Grain Size of Metals

ASTM E139 Coaducting Creep,Creep-Rupture and Stress Rupture Tests oi Metaliic Materials

ASTM A370 mechanical Testing of Steel Products

The following requirements of 1.4404,X2CrNiMo17-12-2 forged parts are acceptance tests and shall be performed on each heat or lot as applicable.

Composition of each heat.

Hardness and average grain size of each lot of bars, forgings, and forged rings as solution heat treated.

Room-temperature tensile properties , hardness , and stress-rupture properties (of each lot of bars, forgings, and forged rings after precipitation heat

treatment.

Microstructure of each lot.

Periodic Tests: The following requirements are periodic tests and shall be performed at a frequency selected by the vendor unless frequency of testing is specified by purchaser:

Tensile Properties

hardness and stress-rupture properties of 1.4404 forged parts after resolution and precipitation heat treatment

Grain flow of X2CrNiMo17-12-2 forgings

Welcome your inquiry of 1.4404,X2CrNiMo17-12-2,X2CrNiMo17122,X2CrNiMo17.12.2 forging forged steel parts