Description

Jiangsu Liangyi professional manufacturer of 1.7366,X16CrMo5-1,X16CrMo51,X16CrMo5.1 open die forging parts and seamless rolled steel forged rings from china

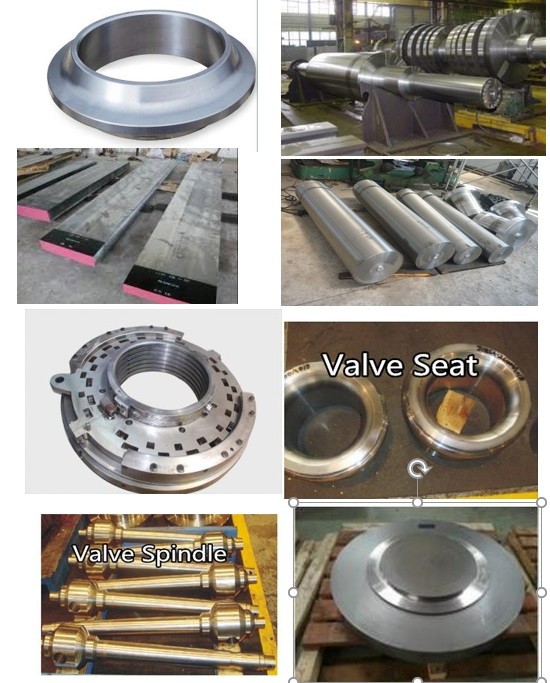

Following is the shape of 1.7366,X16CrMo5-1,X16CrMo51,X16CrMo5.1 forging steel material that we could do is: 1.7366 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,

X16CrMo5-1 Forged forging steel rings seamless rolled rings,X16CrMo5.1 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,1.7366 Forged Forging Steel Discs Disks Blocks plates,X16CrMo51 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 1.7366,X16CrMo5-1,X16CrMo51,X16CrMo5.1 material that is used in following industry

1.7366 Forged Forging Swivel Ring Flanges

X16CrMo5-1 Forging/Forged Forge Steel Wye Piece/Piggable Wyes

X16CrMo5-1 Forged Forging Swept branches outlets steel fittings swept saddles

X16CrMo5-1 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

X16CrMo51 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate pump

X16CrMo51 Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

1.7366 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings

X16CrMo5.1 Forged Forging forge Steel transition Cone

1.7366 Forged Forging Blowout Preventer RAM Annular dual Bops Body Bodies Block

FOllowing is production standard of 1.7366 forged steel material, :

EN 10222-2: 2000 Steel forgings for pressure purposes. Ferritic and martensitic steels with specified elevated temperature properties

FOllowing is melting methods of 1.7366 forged parts

1. Step 1- Basic EF

Step 2- Either Argon Oxygen Decarburization (AOD) or Vacuum Oxygen Decarburization (VOD) or Vacuum Degrassing.

Step 3- Either Electroslag Remelting (ESR) or Electroflux Remelting (EFR) or Vacuum Arc Remelting (VAR).

Optional Step 4- Vacuum Arc Remelting (VAR)

OR

2. Step 1- Vacuum Induction Melting (VIM)

Step 2- Either Electroslag Remelting (ESR) or Electroflux Remelting (EFR) or Vacuum Arc Remelting (VAR).

Optional Step 3- Vacuum Are Remelting (VAR).

FOllowing is chemical compostion of 1.7366, X16CrMo5-1,X16CrMo5-1, X16CrMo51 forged steel rings

Iron (Fe) 91.9 to 95.3

Chromium (Cr) 4.0 to 6.0

Manganese (Mn) 0.3 to 0.8

Molybdenum (Mo) 0.45 to 0.65

Silicon (Si) 0 to 0.4

Carbon (C) 0 to 0.18

Phosphorus (P) 0 to 0.025

Sulfur (S) 0 to 0.015

Following of 1.7366 forging parts mechanical property :

Rm - Tensile strength (MPa) (+A) 410-510

Rm - Tensile strength (MPa) (+NT) 640-780

ReH - Minimum yield strength (MPa) (+A) 205

ReH - Minimum yield strength (MPa) (+NT) 420

KV - Impact energy (J) longitud., +20°40

KV - Impact energy (J) transverse, +20°27

A - Min. elongation at fracture (%) longitud., (+A) 18

A - Min. elongation at fracture (%) longitud., (+NT) 16

We conduct a rigorous and wide range of test and inspection to ensure safe and superior quality products of all our X16CrMo5-1 forging parts

Chemical analysis by ASTM, ASME

Mechanical analysis

Tensile test by ASTM A370, E8/E8M

High temperature tensile test by ASTM E21

Impact test by ASTM A370, E23

Stress rupture test by ASTM E139

Micro structure test by ASTM E407

Macro structure test by ASTM E340, E381

Corrosion test by ASTM A262, A923, G48

NDE (UT, PT, MT) by ASTM A388, A745, MIL-STD-2154

3D Dimensional check

Material certification to EN10204 Type 3.1 of finish 1.7366 forged material should be issued as per following

Material certificate,per batch,referred to this specification are issued by the manufacturershall include as minimum:

Order No.

Grade of material

Cast no.and heat treatment no.

Melting and refining process.

Certified chemical analysis.

Certified record of mechanical properties including impact test.

Certificate of Ultrasonic Test

Welcome your inquiry of 1.7366, X16CrMo5-1,X16CrMo5-1, X16CrMo51 forging forged steel parts