Description

Jiangsu Liangyi is professional manufacturer of AISI 316LN,UNS S31653,Grade 316LN,SUS 316LN,TP 316LN,AISI 316 LN open die forging parts and seamless rolled steel forged rings from china

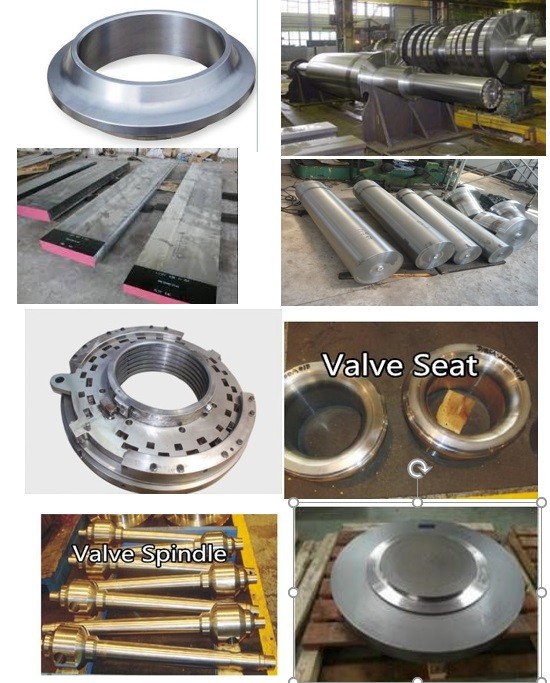

Following is the shape of AISI 316LN,UNS S31653,Grade 316LN,SUS 316LN,TP 316LN,AISI 316 LN forging steel material that we could do is: AISI 316LN Forged Steel round bars square bars Flat bars Rectangles Bars Rods,AISI 316LN Forged forging steel rings seamless rolled rings,UNS S31653 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,UNS S31653 Forged Forging Steel Discs Disks Blocks plates,AISI 316LN Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of AISI 316LN,UNS S31653,Grade 316LN,SUS 316LN,TP 316LN,AISI 316 LN material that is used in following industry

Grade 316LN Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

UNS S31653 Forged Forging Steel nuclear Power

Grade 316LN Forged Forging Steel Butterfly Valve Main Shafts Spindles

UNS S31653 Forged Forging Swept branches outlets steel fittings swept saddles

AISI 316LN Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

AISI 316LN Forged Forging Steels Christmas Trees wellhead Spool Body Bodies cylinder

Grade 316LN Forged Forging venturi cone meter Body Bodies Blocks

UNS S31653 Forged Forging Steel gate valves Body Bodies bespoke flat bars

AISI 316LN forged steel Flowseal cryogenic High Performance BV Butterfly Valves HPBV shaft

Grade 316LN forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

AISI 316LN Forged Forging Steel double studded adapter flange

AISI 316LN Forged Forging Steel integral Mud Flange Flanged outlet Studded crosses

UNS S31653 Forged Forging Steel Casing Heads,Tubing Heads,Casing Hangers,Tubing Hangers,Tubing Spools,Casing Spools,Spacer Spools

AISI 316LN Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

Grade 316LN Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

Duplex Stainless Steel 2205 Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

AISI 316LN Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

UNS S31653 Forged Forging forge Steel transition Cone

UNS S31653 Forged Forging Steel Pressure Vessel Reactor Nozzles

AISI 316LN forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

AISI 316LN is a type of stainless steel that is similar to 316L but has nitrogen added to it. The nitrogen content in 316LN is typically between 0.1-0.2%, which increases the strength of the steel without significantly affecting its corrosion resistance properties.

Compared to standard 316L, 316LN has a slightly higher yield strength, tensile strength, and hardness. 316LN is strong and can be used in high-stress applications like pressure vessels, heat exchangers, and boilers. The steel is resistant to corrosion in hot places because it has nitrogen in its chemical makeup.

FOllowing is chemical compostion of AISI 316LN,Grade 316LN forged steel rings

Iron (Fe): balance

Chromium (Cr): 16-18%

Nickel (Ni): 11-14%

Molybdenum (Mo): 2-3%

Nitrogen (N): 0.1-0.2%

Carbon (C): 0.03% max

Manganese (Mn): 2% max

Silicon (Si): 1% max

Phosphorus (P): 0.045% max

Sulfur (S): 0.03% max

RAW MATERIAL INSPECTION of AISI 316LN forging material

The AISI 316LN forging billet shall be inspected to ensure that material is uniform in structure and chemistry and free from piping,injurious segregation,discontinuities and other foreign materials.Analysis shall be performed by the billet Producer on material representing at least the top and bottom of each ingot

MICRO EXAMINATION of AISI 316LN forged parts

Micrographic examination shall be performed on specimens taken in the mid-radius and center of the section used for macrographic examination to evaluate carbide distribution,delta phase distribution,grain and banding.The micrographic samples shall be mounted and polished in the longitudinal direction with respect to the billet.Dedicated additional micrographic inspection shall be performed in case of anomalies are observed at the macrographic inspection.

Following of AISI 316LN,Grade 316LN forging parts heat treatment nechanical property Delivery condition :

Temper Annealed

Tensile Rm 75 ksi (min)

Tensile Rm 515 MPa (min)

R.p. 0.2% Yield 30 ksi (min)

R.p. 0.2% Yield 205 MPa (min)

Elongation (2” or 4D gl) 35 % (min)

Qualification of manufacturing procedure of AISI 316LN,UNS S31653 forging parts

The Manufacturing Process Plan (MPP) shall be submitted to the approval of clients Material

& Process Engineering dept. clients before qualification procedure begins. It shall detail at least

the following:

• type of ingot (supplier, manufacturing process, dimensions, and tests to beperformed);

• forging process;

• heat treatment process;

• tests on component.

In general, dissection of the first piece within the terms detailed in the part specification is required.

This activity may be omitted, upon decision of clients, if the supplier has already proven to be able to successfully produce components of similar shape, dimensions and manufacturing

process.

Welcome your inquiry of AISI 316LN,UNS S31653,Grade 316LN,SUS 316LN,TP 316LN,AISI 316 LN forging forged steel parts

Following is the shape of AISI 316LN,UNS S31653,Grade 316LN,SUS 316LN,TP 316LN,AISI 316 LN forging steel material that we could do is: AISI 316LN Forged Steel round bars square bars Flat bars Rectangles Bars Rods,AISI 316LN Forged forging steel rings seamless rolled rings,UNS S31653 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,UNS S31653 Forged Forging Steel Discs Disks Blocks plates,AISI 316LN Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of AISI 316LN,UNS S31653,Grade 316LN,SUS 316LN,TP 316LN,AISI 316 LN material that is used in following industry

Grade 316LN Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

UNS S31653 Forged Forging Steel nuclear Power

Grade 316LN Forged Forging Steel Butterfly Valve Main Shafts Spindles

UNS S31653 Forged Forging Swept branches outlets steel fittings swept saddles

AISI 316LN Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

AISI 316LN Forged Forging Steels Christmas Trees wellhead Spool Body Bodies cylinder

Grade 316LN Forged Forging venturi cone meter Body Bodies Blocks

UNS S31653 Forged Forging Steel gate valves Body Bodies bespoke flat bars

AISI 316LN forged steel Flowseal cryogenic High Performance BV Butterfly Valves HPBV shaft

Grade 316LN forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

AISI 316LN Forged Forging Steel double studded adapter flange

AISI 316LN Forged Forging Steel integral Mud Flange Flanged outlet Studded crosses

UNS S31653 Forged Forging Steel Casing Heads,Tubing Heads,Casing Hangers,Tubing Hangers,Tubing Spools,Casing Spools,Spacer Spools

AISI 316LN Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

Grade 316LN Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

Duplex Stainless Steel 2205 Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

AISI 316LN Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

UNS S31653 Forged Forging forge Steel transition Cone

UNS S31653 Forged Forging Steel Pressure Vessel Reactor Nozzles

AISI 316LN forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

AISI 316LN is a type of stainless steel that is similar to 316L but has nitrogen added to it. The nitrogen content in 316LN is typically between 0.1-0.2%, which increases the strength of the steel without significantly affecting its corrosion resistance properties.

Compared to standard 316L, 316LN has a slightly higher yield strength, tensile strength, and hardness. 316LN is strong and can be used in high-stress applications like pressure vessels, heat exchangers, and boilers. The steel is resistant to corrosion in hot places because it has nitrogen in its chemical makeup.

FOllowing is chemical compostion of AISI 316LN,Grade 316LN forged steel rings

Iron (Fe): balance

Chromium (Cr): 16-18%

Nickel (Ni): 11-14%

Molybdenum (Mo): 2-3%

Nitrogen (N): 0.1-0.2%

Carbon (C): 0.03% max

Manganese (Mn): 2% max

Silicon (Si): 1% max

Phosphorus (P): 0.045% max

Sulfur (S): 0.03% max

RAW MATERIAL INSPECTION of AISI 316LN forging material

The AISI 316LN forging billet shall be inspected to ensure that material is uniform in structure and chemistry and free from piping,injurious segregation,discontinuities and other foreign materials.Analysis shall be performed by the billet Producer on material representing at least the top and bottom of each ingot

MICRO EXAMINATION of AISI 316LN forged parts

Micrographic examination shall be performed on specimens taken in the mid-radius and center of the section used for macrographic examination to evaluate carbide distribution,delta phase distribution,grain and banding.The micrographic samples shall be mounted and polished in the longitudinal direction with respect to the billet.Dedicated additional micrographic inspection shall be performed in case of anomalies are observed at the macrographic inspection.

Following of AISI 316LN,Grade 316LN forging parts heat treatment nechanical property Delivery condition :

Temper Annealed

Tensile Rm 75 ksi (min)

Tensile Rm 515 MPa (min)

R.p. 0.2% Yield 30 ksi (min)

R.p. 0.2% Yield 205 MPa (min)

Elongation (2” or 4D gl) 35 % (min)

Qualification of manufacturing procedure of AISI 316LN,UNS S31653 forging parts

The Manufacturing Process Plan (MPP) shall be submitted to the approval of clients Material

& Process Engineering dept. clients before qualification procedure begins. It shall detail at least

the following:

• type of ingot (supplier, manufacturing process, dimensions, and tests to beperformed);

• forging process;

• heat treatment process;

• tests on component.

In general, dissection of the first piece within the terms detailed in the part specification is required.

This activity may be omitted, upon decision of clients, if the supplier has already proven to be able to successfully produce components of similar shape, dimensions and manufacturing

process.

Welcome your inquiry of AISI 316LN,UNS S31653,Grade 316LN,SUS 316LN,TP 316LN,AISI 316 LN forging forged steel parts