Description

Jiangsu Liangyi professional manufacturer of 07Х16Н4Д4Б - 07Х16Н4ДБ- 07Ch16N4D4B - 07Ch16N4DB open die forging parts and seamless rolled steel forged rings. 07Х16Н4Д4Б forged steel steam gas turbine blade steel, 07Х16Н4ДБ forging steel turbine pump impeller from china

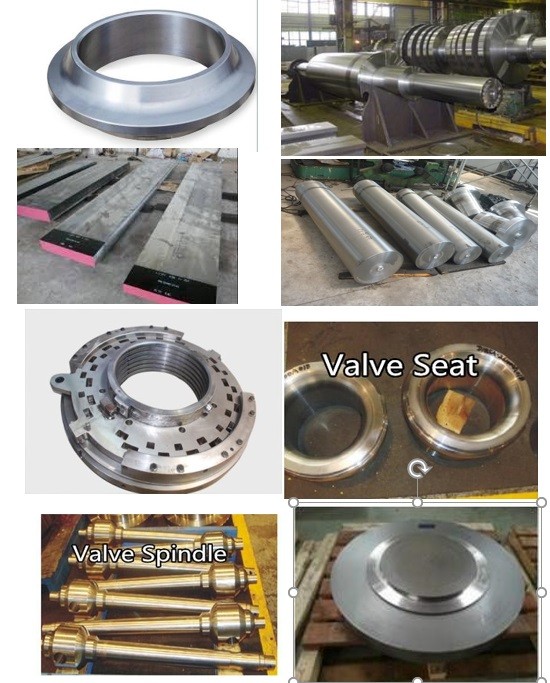

Following is the shape of 07Х16Н4Д4Б - 07Х16Н4ДБ- 07Ch16N4D4B - 07Ch16N4DB forging steel material that we could do is:07Х16Н4Д4Б Forged Steel round bars square bars Flat bars Rectangles Bars Rods,07Ch16N4DB Forged forging steel rings seamless rolled rings,07Х16Н4ДБ Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,07Х16Н4ДБ Forged Forging Steel Discs Disks Blocks plates,07Ch16N4D4B Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 07Х16Н4Д4Б - 07Х16Н4ДБ- 07Ch16N4D4B - 07Ch16N4DB material that is used in following industry

07Х16Н4Д4Б Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

07Х16Н4ДБ Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

07Ch16N4D4B Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

07Х16Н4Д4Б Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

07Ch16N4DB forged forging steel pump case, pump impeller, pump wear rings, pump shafts

07Х16Н4ДБ forged forging steel valve bonnet, valve body, valve closure, valve stems, valve seat rings, valve core, valve discs

07Ch16N4D4B forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

The melting methods of 07Х16Н4Д4Б - 07Х16Н4ДБ- 07Ch16N4D4B - 07Ch16N4DB forged steam turbine blade steel is as follows: The Steel shall be made using the basic electric furnace process with either the Electro-Slag Re-Melt (ESR) or Vacuum- Arc-Re-Melt(VAR) process. Alloy melting requirements shall be compatible with AMS5773E.

07Х16Н4Д4Б - 07Х16Н4ДБ is a martensitic precipitation-hardening stainless steel that provides high strength, good

corrosion resistance, good mechanical properties at temperatures up to 600°F(316°C) and good toughness in both the

longitudinal and transverse directions in both base metal and welds. Short-time,low-temperature heat treatments minimize distortion and scaling.

FOllowing is chemical compostion of 07Х16Н4Д4Б - 07Х16Н4ДБ forged steel flat bars

C 0.05 - 0.1

Si 0.6 max

Mn 0.2 - 0.5

Ni 3.5 - 4.5

S 0.02 max

P 0.025 max

Cr 15 - 16.5

Nb 0.2 - 0.4

07Х16Н4Д4Б - 07Х16Н4ДБ forging steel turbine blade flat bars heat treat way is as follows:

07Х16Н4Д4Б - 07Х16Н4ДБ forged material is in the solution annealed condition is heated for one hour at 482 °C ± 8 °C (900 °F ± 15 °F)*and air cooled to room temperature. , it must be solution annealed after such working and before hardening. Likewise, material age hardened at one temperature cannot be rehardened at a lower

temperature without re-solution heat treating.

All surfaces of finished 07Х16Н4Д4Б - 07Х16Н4ДБ forged parts should be free of cutting lubricants, paint, adhesives, labels,and other foreign matter before any heat-treating operation is performed.

Where ductility in the hardened condition is especially important, better toughness can be obtained by raising the temperature of the hardening heat treatment. Unlike regular hardenable materials which require a

hardening plus a tempering or stress-relieving treatment, solution treatment of 07Х16Н4Д4Б - 07Х16Н4ДБ forging materual can be hardenedto the final desired properties in one operation. By heat treating at

temperatures from 482 – 621 °C (900 – 1150 °F), a wide range of properties can be attained. A heat treatment of four hours is generally used for all hardening heat treatments except 482 °C (900 °F), forwhich a one-hour treatment is used.

Mechanical properties of 07Х16Н4Д4Б - 07Х16Н4ДБ forged round bars shall be tested at room temperature (23 ± 5degree),

Ultimate tensile strength, Rm, MPa 882

l yield strength, Rp0.2,MPa, min 690

Elongation A,%, min 11

Reudction % min 55

For melting 07Х16Н4Д4Б - 07Х16Н4ДБ forging steel material, we have following melting equipment

60 t Electric Arc Furnace (EAF) / Power 40 MVA

2 Ladle Furnace (LF)

2 Tank Degassing VD - VOD type

Pits for bottom pouring

ESR Plant (max weight 32 t)

In order to make forging and make heat treatment 07Х16Н4Д4Б - 07Х16Н4ДБ forging RIngs, we have following production equipment

Forging Process:3200/4200/6000 t Open die presses

Manipulators, Lifting Capacity up to 60 t

Heating Forging Furnaces, Max Capacity 150 t

Furnaces for Hydrogen Bake-Out Up to 14 m

Heat Treatment Semi-automatic Heat Treatment System Quality Heat Treatment

Furnaces Max lenght 18 m Quenching tanks up to 16 m

Welcome your inquiry of 07Х16Н4Д4Б - 07Х16Н4ДБ forging forged steel parts