Description

Ww are professeional manufacturer of Forging forging Steel Mandrel Segment for Cold Rolling Mill Uncoiler Coiler,Forged forging steel Mandrel Segment for Hot Strip Mill Down-Coilers. forging Mandrel Segment for Coiling and rolling mill equipment ,forged Mandrel Segment for ROlling Mill coiling and uncoiling

Following is material grade that used in forging steel Mandrel Segment

AISI 1045,AISI 4140,AISI 4340,,42CrMo4,1.4923 X22CrMoV12-1,25CrMo4,34CrNiMo6,17CrNiMo6-4, 20NiCrMo22,34CrMo4,30CrNiMo8,36CrNiMo4,16CrNiMo12,40NiCrMo7,41CrALMo7,30NiCrMo12,12CrMo9-10,,18CrNiMo7-6,17CrNiMo6,,50CrMo4,39NiCrMo3

Melting methods of forged steel Mandrel Segment :Electrical Furnace Melting+Full Vacuum Degassed

Forged Mandrel Segment of Forging ratio min. 4 : 1

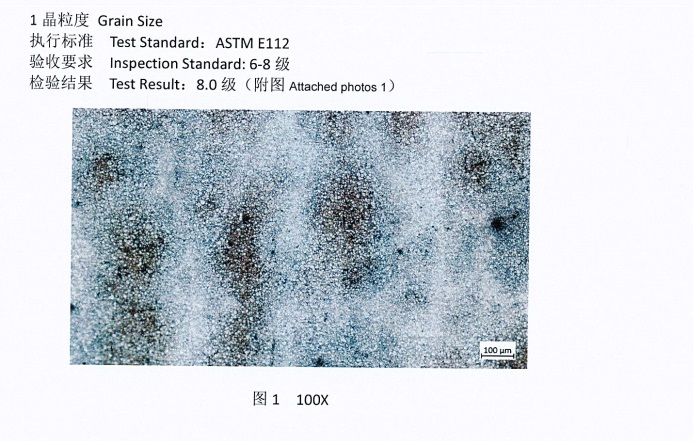

Forged Mandrel Segment Grain size is 6-8 ASTM

All our forged Forged Mandrel Segment will do Oil hardened & tempered to meeting following mechnical property

Yield: 700 N/mm² min.

U.T.S.: 850-950 N/mm²

Elongation: 15%

Impact value: min. 34J at room temp.

Hardness: 240-290 BHN

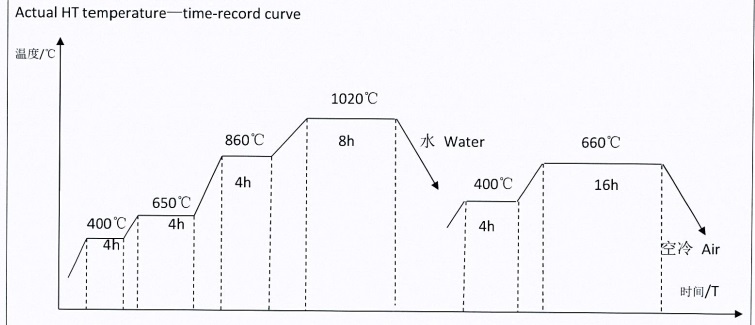

FOllowing is heat treatment chart of forged steel mandrel segment

All our forged mandrel segment will be done 100% Ultrasonically tested to ASTM A388

All our forged mandrel segment will be done Magnetic Particle Examination to ASTM A275

We could forged, heat treatment , final machined mandrel segment as per clients drawing