Description

Jiangsu Liangyi professional manufacturer of 27NiCrMoV11-6,27NiCrMoV116,27NiCrMoV11.6,27 NiCrMoV116 open die forging parts and forged steel gas steam turbine generator rotor shafts factory from china

27NiCrMoV11-6 is Creep resisting steel, hardened and tempered as per standard of SEW 555 (1984) Steels for larger forgings for components in turbine and generator production, such as turbine bolts, turbine rotor shafts, turbine blades and so on

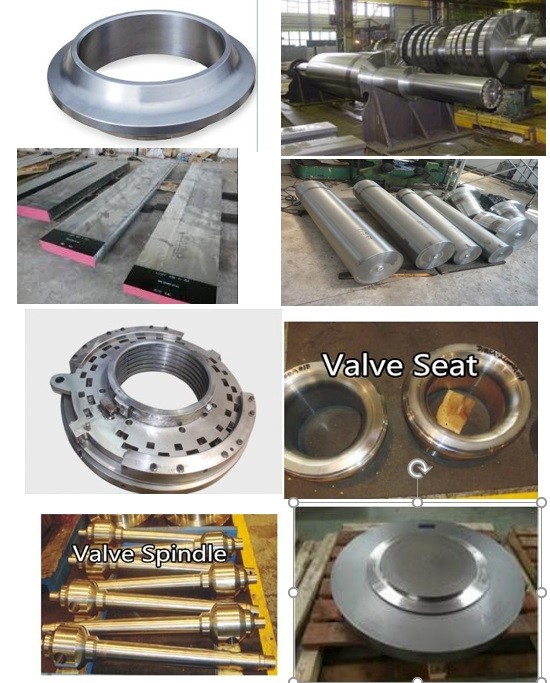

Following is the shape of 27NiCrMoV11-6,27NiCrMoV116,27NiCrMoV11.6,27 NiCrMoV116 forging steel material that we could do is:27NiCrMoV116 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,27NiCrMoV11-6 Forged forging steel rings seamless rolled rings, 27NiCrMoV11.6 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,27NiCrMoV11-6 Forged Forging Steel Discs Disks Blocks plates, 27NiCrMoV116 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.27NiCrMoV11-6 Forged Forging Steel Gas Steam Turbine Rotors Shafts,27 NiCrMoV 11-6 Forged Forging Gas Compressor Turbine Blades turbine Vane steel Flat Rectangles Bars,27NiCrMoV11-6 Forged Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings,,27NiCrMoV11.6 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,27NiCrMoV116 Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

The chemical compostion of 27NiCrMoV11.6 forging parts is as follow

Carbon (C%)Min: 0,22 Max: 0,32

Manganese (Mn%) Min: 0,15 Max: 0,40

Silicon (Si%) ≤ 0,15

Phosphorus (P%)≤0,01

Sulfur (S%)≤0,007

Chrome (Cr%) Min: 1,20 Max: 1,80

Nickel (Ni%) Min: 2,40 Max: 3,10

Molybdenum (Mo%)Min: 0,25 Max: 0,45

Vanadium (V%) Min: 0,05 Max: 0,15

The mechanical property of SEW 26 NiCrMoV 11 5 forging turbine rotor shafts is as follow

YieldRp0.2 (MPa)≥700

Tensile Rm (MPa)≥900-1050

Impact KV/Ku (J)≥55

Elongation A ≥(%)14

We have following melting equipment for our 27NiCrMoV11-6 forged turbine shafts raw material:

• 40 tonne capacity Electric Arc Furnace (EAF)

• 50 tonne Vacuum Arc Degasser (VAD)

• Ladle Furnace (LF)

• 50tonne Vacuum Oxygen Decarburisation unit (VOD)

• Lifting capacity 80 tons

8000 tonne Open Die Hydraulic Forging Press,Capable of complex 27NiCrMoV11-6 forgings up to 80 tonnes.Max Dias - forged Discs – Ø3080mm,forging Tubes – 2050mmOD x 1900mmID,forged Rings 4560mmOD x 3000mmID, forging Shafts Ø2100mm |,forged Collars Ø3048mm,Max Length - 15800mm

4500 tonne Open Die Hydraulic Forging Press Typical weights from 6 up to 40 tonnes. Min Dia - Ø270mm,Max Length - 12000mm

Our wide range of traditional and vertical heat treatment facilities are designed to produce our 27NiCrMoV11-6 forged gas turbine rotor shafts,capacity is 7,600 x 5,000 x 17,500mm(w x h x l)

Our workshop also include a vast array of milling, turning, boring and finishing machinery Vertical Turning Lathe and Horizontal Floor Borer, to final machined of 27NiCrMoV11-6 forged turbine shafts as per clients drawing

For NDT test for all our 27NiCrMoV11-6 forging parts, All Our NDT personnel are PCN and SNT-TC-1A qualified and certified in Non-Destructive Testing to level 2 or 3.All Our Level III and Level II industry certified NDT engineering team is trained inconventional and advanced techniques including radiography, ultrasonic, dye penetrant &magnetic particle to evaluate the material properties of a 27NiCrMoV11-6 forging material without damage.

All our 27NiCrMoV11-6 forging turbine rotor shafts will have following testing procedure

Visual inspections – Direct and Indirect

Magnetic particle

Dye penetrant – Visible and Fluorescent

Ultra-sonic testing

Radiograph

Metallurgical Testing

Macro & micro

Grain size determination

Charpy Impact testing

V notch Charpy

Hardness testing including micro and

macro Vickers tests

Tensile testing

Microscope imaging