Description

Jiangsu Liangyi is professional manufacturer of ASTM A564 Grade 634,Type 634,AISI 634,Alloy 634 open die forging forged parts forged forging rings and forged forging steel gas steam turbine parts factory from china

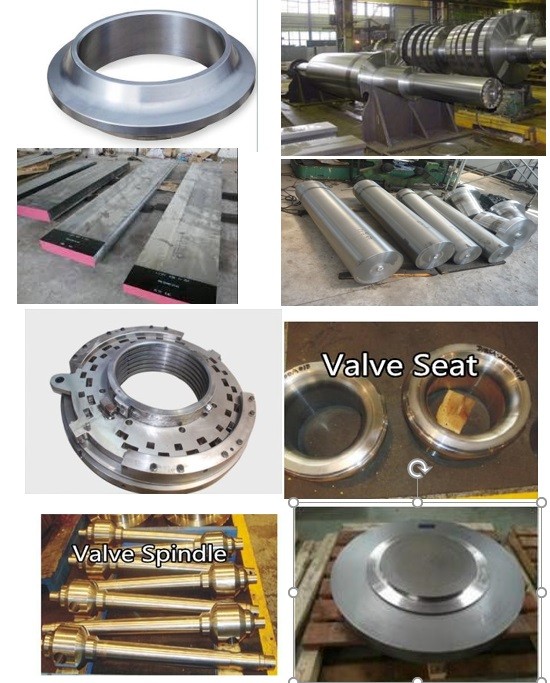

Following is the shape of ASTM A564 Grade 634,Type 634,AISI 634,Alloy 634 forging steel material that we could do is:ASTM A564 Grade 634,Type 634,AISI 634,Alloy 634 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,AISI 634 Forged forging steel rings seamless rolled rings,ASTM A564 Grade 634 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,Type 634Forged Forging Steel Discs Disks Blocks plates,ASTM A564 Grade 634 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of ASTM A564 Grade 634 that is used in gas steam turbine

ASTM A564 Grade 634 Forged Forging Steel Gas Steam Turbine blade steel

ASTM A564 Grade 634 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

AISI 634 Forged Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings/Blade Fitting Rings

AISI 634 Forging Forged Steel Gas Turbine Wheels Discs turbine impeller turbine blisks

Type 634 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

Type 634 Forged Forging Rolled Steel Gas Turbine LPT 1st & 2st 2nd Stg Stage Steam Turbine shrouds turbines journal and thrust bearing

Type 634 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

ASTM A564 Grade 634 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

ASTM A564 Grade 634 Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

ASTM A564 Grade 634 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

ASTM A564 Grade 634 Forged Forging Steel Gas Steam Turbine Oil Guards nozzle Bearing Gland Seal Sealing Rings,

ASTM A564 Grade 634 forging Steam Gas Turbine Inlet Guide Vane IGV Control Ring Lower Upper Half,Outer Inner Transition Ducts,

ASTM A564 Grade 634 forged Forged Forging Rolled Gas Steam Turbine Inner Outer Heat Shields,

The maximum diamter of ASTM A564 Grade 634 forging steel parts in we could produce is 3 meter, the maximum weight of AISI 634 forging steel material that we could produce is 25 tons, the maximum length of Type 634 forging steel products that we could do is 12 meter

Our AISI 634 forged steel raw material is normal melting by Basic Electric Furnace (EAF, AOD, VOD) or + Electroslag remelting. (ESR) AS PER CLIENTS NEEDS

AISI 634, ASTM A564 Grade 634 is chromium nickel molybdenum stainless steel. AM 355 is a heat treatable austentic/ martensitic alloy (depending on the heat treatment). The properties of AM355 are that of strength of a heat treatable martensitic grades with the corrosion resistance of some of the chromium nickel austenitic grades. AISI 634, ASTM A564 Grade 634 is used for blades, knives, industrial cutters, discs, rotors, shafts and in similar parts where high strength is required at intermediate elevated temperatures.

The chemical compostion of ASTM A564 Grade 634 forging parts that we could produce is as followings

Iron (Fe) 73.2 to 77.7

Chromium (Cr) 15 to 16

Nickel (Ni) 4.0 to 5.0

Molybdenum (Mo) 2.5 to 3.2

Manganese (Mn) 0.5 to 1.3

Niobium (Nb) 0.1 to 0.5

Silicon (Si) 0 to 0.5

Carbon (C) 0.1 to 0.15

Nitrogen (N) 0.070 to 0.13

Phosphorus (P) 0 to 0.040

Sulfur (S) 0 to 0.030

FOllowing is heat treatment mechanical property of ASTM A564 Grade 634,Type 634,AISI 634,Alloy 634 forging steel turbine parts

Reduction of area MIn 25 %

Tensile strength MIn 1170 MPa

Yield strength Rp0.2 MIn 1070 MPa

Following is heat treatment way of ASTM A564 Grade 634 forged parts

Annealing

Heat to 1850/1900 °F(1024/1038 °C) and cool rapidly

Hardening

The alloy can be hardened by either sub-zero cooling or by a double-aging treatment. Hardening by sub-zero cooling will result in higher strength than that attained by double aging. "Condition" of the alloy by rapid cooling from 1710/1750 °F(932/954 °C) is required before either hardening treatnment.

After conditioning, the alloy is held at -100 Deg F for a minimum of 3 hours and then tempered at 850 °F for the best combination of strength and ductility. If, however, applications required better finish machining characteristics, higher impact strengths, or higher ductilities than are provided by an 850 °F temper, tempering temperatures up to 1000 °F may be employed. Optimum stress-corrosion-cracking resistance is provided by the 1000 °F temper.

1350/1400 °F(732/760 °C) for 3-4 hours, rapid cool; 825/875 °F (440/468 °C) for 2-3 hours , air cool. The 1350/1400 °F treatment results in carbide precipitation so that the material will completely transform to martensite when rapidly cooled to room temperature. The treatment at 825/875 °F after transformation provides further increases in strength and hardness.

All our finish production of ASTM A564 Grade 634,Type 634,AISI 634,Alloy 634 forged steel material should will done in Following NDE shall be performed in delivery condition:

- Visual inspection

Material verification test

- 100% UT- inspection according to EN 10228-3 (table 3). Depending on the forging geometry,

following inspection types are applicable:

- for ASTM A564 Grade 634 forging bar shape components; type 1 (inspection may also be carried out as per EN10308 for type 1)

- for Type 634 forged discs and plate- like components: type 2

- for Alloy 634 forging ring or bushing- like components: type 3b and 3

Welcome your inquiry of ASTM A564 Grade 634,Type 634,AISI 634,Alloy 634 forging forged steel parts

Following is the shape of ASTM A564 Grade 634,Type 634,AISI 634,Alloy 634 forging steel material that we could do is:ASTM A564 Grade 634,Type 634,AISI 634,Alloy 634 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,AISI 634 Forged forging steel rings seamless rolled rings,ASTM A564 Grade 634 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,Type 634Forged Forging Steel Discs Disks Blocks plates,ASTM A564 Grade 634 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of ASTM A564 Grade 634 that is used in gas steam turbine

ASTM A564 Grade 634 Forged Forging Steel Gas Steam Turbine blade steel

ASTM A564 Grade 634 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

AISI 634 Forged Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings/Blade Fitting Rings

AISI 634 Forging Forged Steel Gas Turbine Wheels Discs turbine impeller turbine blisks

Type 634 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

Type 634 Forged Forging Rolled Steel Gas Turbine LPT 1st & 2st 2nd Stg Stage Steam Turbine shrouds turbines journal and thrust bearing

Type 634 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

ASTM A564 Grade 634 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

ASTM A564 Grade 634 Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

ASTM A564 Grade 634 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

ASTM A564 Grade 634 Forged Forging Steel Gas Steam Turbine Oil Guards nozzle Bearing Gland Seal Sealing Rings,

ASTM A564 Grade 634 forging Steam Gas Turbine Inlet Guide Vane IGV Control Ring Lower Upper Half,Outer Inner Transition Ducts,

ASTM A564 Grade 634 forged Forged Forging Rolled Gas Steam Turbine Inner Outer Heat Shields,

The maximum diamter of ASTM A564 Grade 634 forging steel parts in we could produce is 3 meter, the maximum weight of AISI 634 forging steel material that we could produce is 25 tons, the maximum length of Type 634 forging steel products that we could do is 12 meter

Our AISI 634 forged steel raw material is normal melting by Basic Electric Furnace (EAF, AOD, VOD) or + Electroslag remelting. (ESR) AS PER CLIENTS NEEDS

AISI 634, ASTM A564 Grade 634 is chromium nickel molybdenum stainless steel. AM 355 is a heat treatable austentic/ martensitic alloy (depending on the heat treatment). The properties of AM355 are that of strength of a heat treatable martensitic grades with the corrosion resistance of some of the chromium nickel austenitic grades. AISI 634, ASTM A564 Grade 634 is used for blades, knives, industrial cutters, discs, rotors, shafts and in similar parts where high strength is required at intermediate elevated temperatures.

The chemical compostion of ASTM A564 Grade 634 forging parts that we could produce is as followings

Iron (Fe) 73.2 to 77.7

Chromium (Cr) 15 to 16

Nickel (Ni) 4.0 to 5.0

Molybdenum (Mo) 2.5 to 3.2

Manganese (Mn) 0.5 to 1.3

Niobium (Nb) 0.1 to 0.5

Silicon (Si) 0 to 0.5

Carbon (C) 0.1 to 0.15

Nitrogen (N) 0.070 to 0.13

Phosphorus (P) 0 to 0.040

Sulfur (S) 0 to 0.030

FOllowing is heat treatment mechanical property of ASTM A564 Grade 634,Type 634,AISI 634,Alloy 634 forging steel turbine parts

Reduction of area MIn 25 %

Tensile strength MIn 1170 MPa

Yield strength Rp0.2 MIn 1070 MPa

Following is heat treatment way of ASTM A564 Grade 634 forged parts

Annealing

Heat to 1850/1900 °F(1024/1038 °C) and cool rapidly

Hardening

The alloy can be hardened by either sub-zero cooling or by a double-aging treatment. Hardening by sub-zero cooling will result in higher strength than that attained by double aging. "Condition" of the alloy by rapid cooling from 1710/1750 °F(932/954 °C) is required before either hardening treatnment.

After conditioning, the alloy is held at -100 Deg F for a minimum of 3 hours and then tempered at 850 °F for the best combination of strength and ductility. If, however, applications required better finish machining characteristics, higher impact strengths, or higher ductilities than are provided by an 850 °F temper, tempering temperatures up to 1000 °F may be employed. Optimum stress-corrosion-cracking resistance is provided by the 1000 °F temper.

1350/1400 °F(732/760 °C) for 3-4 hours, rapid cool; 825/875 °F (440/468 °C) for 2-3 hours , air cool. The 1350/1400 °F treatment results in carbide precipitation so that the material will completely transform to martensite when rapidly cooled to room temperature. The treatment at 825/875 °F after transformation provides further increases in strength and hardness.

All our finish production of ASTM A564 Grade 634,Type 634,AISI 634,Alloy 634 forged steel material should will done in Following NDE shall be performed in delivery condition:

- Visual inspection

Material verification test

- 100% UT- inspection according to EN 10228-3 (table 3). Depending on the forging geometry,

following inspection types are applicable:

- for ASTM A564 Grade 634 forging bar shape components; type 1 (inspection may also be carried out as per EN10308 for type 1)

- for Type 634 forged discs and plate- like components: type 2

- for Alloy 634 forging ring or bushing- like components: type 3b and 3

Welcome your inquiry of ASTM A564 Grade 634,Type 634,AISI 634,Alloy 634 forging forged steel parts