Description

Jiangsu Liangyi professional manufacturer of 1.4568,X7CrNiAl17-7,X7CrNiAl17.7,X7CrNiAl177 open die forging parts and seamless rolled steel forged rings from china

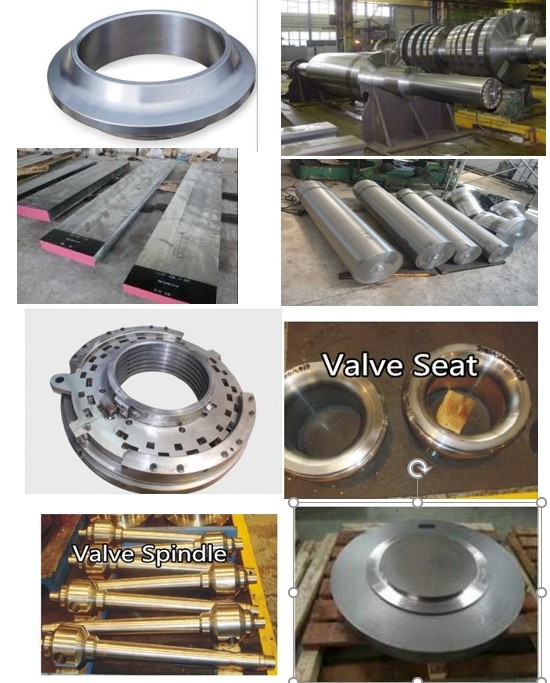

Following is the shape of 1.4568,X7CrNiAl17-7,X7CrNiAl17.7,X7CrNiAl177 forging steel material that we could do is:1.4568 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,X7CrNiAl177,Forged forging steel rings seamless rolled rings,X7CrNiAl17-7 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,X7CrNiAl177 Forged Forging Steel Discs Disks Blocks plates,X7CrNiAl17.7 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 1.4568,X7CrNiAl17-7,X7CrNiAl17.7,X7CrNiAl177 material that is used in following industry

1.4568 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

X7CrNiAl17-7 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

X7CrNiAl17.7 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

X7CrNiAl177 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

1.4568 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

X7CrNiAl177 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate pump

X7CrNiAl17.7Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

X7CrNiAl177 Forged Forging Marine Ship Boat Propeller Shafts

1.4568 Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

1.4568 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps con

X7CrNiAl17.7 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

X7CrNiAl17.7 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings

FOllowing is production standard of 1.4568(X7CrNiAl17-7) forging steel parts

EN 10088-3: 2005 Stainless steels. Technical delivery conditions for semi-finished products, bars, rods, wire, sections and bright products of corrosion resisting steels for general purposes

EN 10088-1: 2005 Stainless steels. List of stainless steels

EN 10088-5: 2009 Stainless steels. Technical delivery conditions for bars, rods, wire, sections and bright products of corrosion resisting steels for construction purposes

1.4568(X7CrNiAl17-7) is s a semi-austenitic precipitation hardening steel with high levels of Chromium and Nickel. It is characterized by high strength and hardness, excellent fatigue properties, minimal distortion upon heat treatment, good formability in the annealed condition, and good corrosion resistance.due to its exceptional mechanical properties, this steel is often used in aerospace applications. It is also used for manufacturing of flat springs, conical springs, washers, eyelets, and strain gauges. 1.4568(X7CrNiAl17-7) Stainless Steel can be used in industrial atmospheres and fresh water due to its good corrosion resistance, but it is not the best choice for use in salt water or reducing environments.

FOllowing is chemical compostion of 1.4568(X7CrNiAl17-7) forged steel sleeves

Iron (Fe) 70.9 to 76.8

Chromium (Cr) 16 to 18

Nickel (Ni) 6.5 to 7.8

Aluminum (Al) 0.7 to 1.5

Manganese (Mn) 0 to 1.0

Silicon (Si) 0 to 0.7

Carbon (C) 0 to 0.090

Phosphorus (P) 0 to 0.040

Sulfur (S) 0 to 0.015

Following of 1.4568(X7CrNiAl17-7) forging parts mechnical property :

Rm - Tensile strength (MPa) (+AT) 850-1030

A - Min. elongation at fracture (%) (+AT) 19

Brinell hardness (HB): (+AT) 255

Heat treatment of 1.4568 / X7CrNiAl17-7 forged steel parts is followings

Annealing

Annealing of stainless steel grade 1.4568 / X7CrNiAl17-7is performed at 1066°C (1950°F) for 3 min for every 0.1 inch (2.5 mm) of thickness, and then air cooled.

Aging

Stainless steel grade 1.4568 / X7CrNiAl17-7is solution annealed at 1177°C (2150°F) for 4 h and air cooled. Same step is performed at 1079°C (1975°F) for 4h and air cooled, then at 843°C (1550°F) for 24h and air cooled, and at 760°C (1400°F) for 16h and air cooled. This completed the precipitation hardening process. For excellent results and performance, the material should be clean and free from scale and impurities.

FOllowing is testing standard of our 1.4568 / X7CrNiAl17-7 forged steel parts

ASTM E10-12: Standard Test Method for Brinell hardness of Metallic Materials;

ASTM A370-12: Standard Test Methods and Definitions for Mechanical Testing of Steel Products;

ASTM E23-07a: Standard Test Methods for Notched Bar Impact Testing of Metallic Materials;

AMS 2315G: Determination of Delta Ferrite Content,

ASTM E45-05: Standard Test Methods for Determining the Inclusion Content of Steel,

ASTM E112-10: Standard Test Methods for Determining Average Grain Size,

ASTM E837: Standard Test Method for Determining Residual Stresses by the Hole-Drilling Strain-Gage Meth

All our finish production of 1.4568 / X7CrNiAl17-7 forged steel material should will done in Following NDE shall be performed in delivery condition:

- Visual inspection

Material verification test

- 100% UT- inspection according to EN 10228-3 (table 3). Depending on the forging geometry,

following inspection types are applicable:

- for 1.4568 forging bar shape components; type 1 (inspection may also be carried out as per EN10308 for type 1)

- for X7CrNiAl17-7 forged discs and plate- like components: type 2

- for X7CrNiAl177 forging ring or bushing- like components: type 3b and 3

Welcome your inquiry of 1.4568 / X7CrNiAl17-7 forging forged steel parts