Description

Jiangsu Liangyi professional manufacturer of 1.4594,X5CrNiMoCuNb14-5,X5CrNiMoCuNb145,X5CrNiMoCuNb14.5 open die forging parts and seamless rolled steel forged rings from china

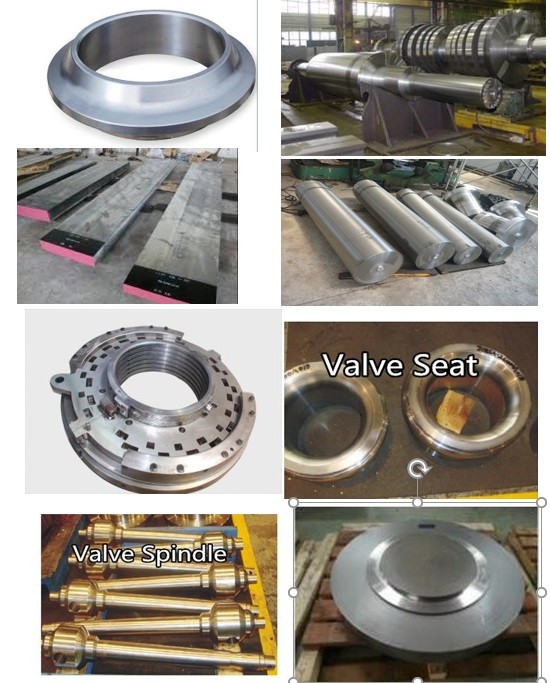

Following is the shape of 1.4594,X5CrNiMoCuNb14-5,X5CrNiMoCuNb145,X5CrNiMoCuNb14.5 forging steel material that we could do is:1.4594 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,X5CrNiMoCuNb14-5 Forged forging steel rings seamless rolled rings,X5CrNiMoCuNb145 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,X5CrNiMoCuNb14.5 Forged Forging Steel Discs Disks Blocks plates,1.4594 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of X5CrNiMoCuNb14-5 material that is used in following industry

1.4594 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

X5CrNiMoCuNb14-5 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

X5CrNiMoCuNb14.5 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

X5CrNiMoCuNb145 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

X5CrNiMoCuNb14.5 forged forging steel pump case, pump impeller, pump wear rings, pump shafts

X5CrNiMoCuNb14-5 forged forging steel valve bonnet, valve body, valve closure, valve stems, valve seat rings, valve core, valve discs

1.4594 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

The melting methods of 1.4594,X5CrNiMoCuNb14-5 forged steam turbine blade steel is as follows: The Steel shall be made using the basic electric furnace process with either the Electro-Slag Re-Melt (ESR) or Vacuum- Arc-Re-Melt(VAR) process. Alloy melting requirements shall be compatible with AMS5773E.

X5CrNiMoCuNb14-5 is a specialized age-hardenable martensitic stainless steel that provides moderate strength and enhanced corrosion resistance. 1.4594 stainless steel alloy is also easily fabricated and maintains good ductility and toughness in a wide range of applications.

FOllowing is chemical compostion of Custom 450 forged steel flat bars

Nitrogen, max 0.03Iron (Fe) 72.6 to 79.5

Chromium (Cr) 13 to 15

Nickel (Ni) 5.0 to 6.0

Molybdenum (Mo) 1.2 to 2.0

Copper (Cu) 1.2 to 2.0

Manganese (Mn) 0 to 1.0

Niobium (Nb) 0.15 to 0.6

Silicon (Si) 0 to 0.7

Carbon (C) 0 to 0.070

Phosphorus (P) 0 to 0.040

Sulfur (S) 0 to 0.015

Fe Balance

Mechanical properties of steel X5CrNiMoCuNb14-5 (1.4594) forged steel bars

Rm - Tensile strength (MPa) : 1000-1200MPA

Rp0.2 0.2% proof strength (MPa) :Min 860MPA

KV - Impact energy (J) longitud., +20° Min 40J

A - Min. elongation at fracture (%) 10-15

Brinell hardness (HB): (+AT) 360

FOllowing is testing standard of our X5CrNiMoCuNb14-5 forged steel turbine blade flat bats

ASTM E10-12: Standard Test Method for Brinell hardness of Metallic Materials;

ASTM A370-12: Standard Test Methods and Definitions for Mechanical Testing of Steel Products;

ASTM E23-07a: Standard Test Methods for Notched Bar Impact Testing of Metallic Materials;

AMS 2315G: Determination of Delta Ferrite Content,

ASTM E45-05: Standard Test Methods for Determining the Inclusion Content of Steel,

ASTM E112-10: Standard Test Methods for Determining Average Grain Size,

ASTM E837: Standard Test Method for Determining Residual Stresses by the Hole-Drilling Strain-Gage Method,

For our finished production of X5CrNiMoCuNb14-5 forged steel bars should have following inspection report

Identification number, material number and designation, order number, drawing number,

Specification Number;

- Heat number, heat chemical analysis, melting method and product chemical analysis;

- Certificate of heat treatment including method of cooling, actual part temperature, holding

time, cooling condition and all re-heat-treatments by complete graphic temperature time;

- Nondestructive testing records,

- Results of all Mechanical Tests,

-Results of residual stress measurements (for process qualification),

- All probable deviation reports,

- Certification of NDT inspector,

- Dimensional and visual inspection report,

- Cleaning Verified