Description

Jiangsu Liangyi professional manufacturer of 1.4911,X8CrCoNiMo10-6,Z10CKD10,X8CrCoNiMo10.6,X8CrCoNiMo106 open die forging parts and seamless rolled steel forged rings,forging steel gas steam turbine blade steel flat bars from china

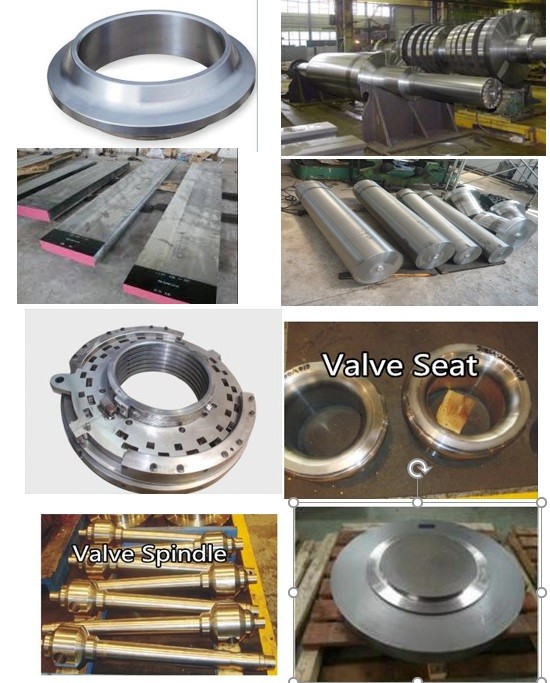

Following is the shape of 1.4911,Z10CKD10.X8CrCoNiMo10-6,X8CrCoNiMo10.6,X8CrCoNiMo106 forging steel material that we could do is:1.4911,X8CrCoNiMo10-6,X8CrCoNiMo10.6,X8CrCoNiMo106 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,X8CrCoNiMo10-6 Forged forging steel rings seamless rolled rings,1.4911 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,Z10CKD10 Forged Forging Steel Discs Disks Blocks plates,X8CrCoNiMo106 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 1.4911,Z10CKD10 that is used in gas steam turbine

1.4911,X8CrCoNiMo10-6 Forged Forging Steel Gas Steam Turbine blade steel

Z10CKD10 forged forging steel gas steam turbine rotor shafts

1.4911,X8CrCoNiMo10-6 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

X8CrCoNiMo10-6 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

X8CrCoNiMo106 Forged Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings/Blade Fitting Rings

X8CrCoNiMo10.6 Forging Forged Steel Gas Turbine Wheels Discs turbine impeller turbine blisks

1.4911 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

Z10CKD10 Forged Forging Rolled Steel Gas Turbine LPT 1st & 2st 2nd Stg Stage Steam Turbine shrouds turbines journal and thrust bearing

X8CrCoNiMo10.6 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

X8CrCoNiMo10-6 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

1.4911 Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

X8CrCoNiMo10-6 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

X8CrCoNiMo106 Forged Forging Steel Gas Steam Turbine Oil Guards nozzle Bearing Gland Seal Sealing Rings,

X8CrCoNiMo10.6 forging Steam Gas Turbine Inlet Guide Vane IGV Control Ring Lower Upper Half,Outer Inner Transition Ducts,

X8CrCoNiMo106 forged Forged Forging Rolled Gas Steam Turbine Inner Outer Heat Shields,

1.4911,X8CrCoNiMo10-6,Z10CKD10 is special martensitic creep-resisting steel and is widely use in Aerospace and energy industry: turbine parts, compressor parts and various parts

FOllowing is production standard of 1.4911,X8CrCoNiMo10-6,Z10CKD10 forging steam turbine blade steel

EN 10302: 2008 Creep resisting steels, nickel and cobalt alloys

EN 10088-1: 2005 Stainless steels. List of stainless steels

FOllowing is melting methods of 1.4911,X8CrCoNiMo10-6,Z10CKD10 forged steel turbine parts:EAF + VD + LF / BEF + ESR

Jiangsu Liangyi has the complete production line at its disposal – from melting, forging and heat treatment through tomachining on CNC-controlled equipment for our all 1.4911,X8CrCoNiMo10-6 forging steel material

Our current integrated management system (IMS) of our 1.4911 forging turbine parts is certified by independent external bodies, which regularly review and confirm our compliance with the standards ISO 9001, ISO 14001 and ISO 50001. Furthermore, there are customer and industry-specific approvals, confirming the conformity of our IMS with the relevant requirements

Following is production process of 1.4911,X8CrCoNiMo10-6,Z10CKD10 forging steel parts

Forging process flow quality control: Raw material steel ingot into warehouse(test the chemical content) → Cutting→ Forged process→ Post forging heat treatment(N+T)→ UT→ Rough Machining→ UT → QT→ Inspection(UT, mechanical properties, hardness, grain size)→ Grooving→ Stress relieve Tempering → Machining holding postion for rotor when HST→ HST→ Inspection (dimension)→ Packing and Marking(steel stamp, mark)→ Storage Shipment

Chemical composition % of steel X8CrCoNiMo10-6 forged steel round bars is as following

C:0.05~0.12

Si:0.10~0.80

Mn:0.20~1.35

P:≤0.025

S:≤0.020

Co:5.0~7.0

Cr:9.80~11.5

Mo:0.50~1.00

Ni:0.20~1.20

V:0.10~0.60

Rm - Tensile strength (MPa) (+QT) 1000-1140

Rp0.2 0.2% proof strength (MPa) (+QT) Minimum 850

A - Min. elongation at fracture (%) (+QT) Minimum 10