Description

Jiangsu Liangyi professional manufacturer of 2.4975(2.4662 ,NiFeCr12Mo, NiFeCr 12 Mo) open die forging parts and seamless rolled steel forged rings from china

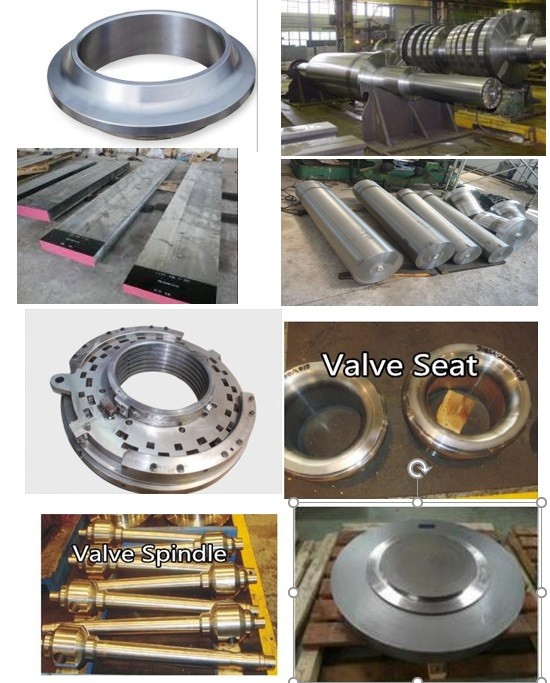

Following is the shape of 2.4975(2.4662 ,NiFeCr12Mo, NiFeCr 12 Mo) forging steel material that we could do is: 2.4975 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,2.4975 Forged forging steel rings seamless rolled rings, 2.4975 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,NiFeCr12Mo Forged Forging Steel Discs Disks Blocks plates,2.4662 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 2.4975(2.4662 ,NiFeCr12Mo, NiFeCr 12 Mo) material that is used in following industry

2.4975 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

2.4662 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

2.4975 forged material for nuclear power such as :Flow limiter Venturi forgings (steam generator),Forged tubes for pressurizer surge line,reactor nozzles and primary pump fly wheels, divider plates for steam generator,Latch housings, rod travel housings and funnel extension,end ring and rotor stack plate forgings,bearing housings and stator end cap and closure ring forgings,Containment plates, rings and closure heads,Waste Flasks and Mounting Skirt,RPV Upper Shell and HSG Shell,Shell Strakes and Transition Cones,Pressure Components,Lifting Pin Tools and Trunnions,Pressuriser Upper Head and Upper Shell,Steam Drumhead and Lifting Pintles

2.4975 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

NiFeCr12Mo Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

NiFeCr12Mo Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

2.4662 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

2.4975 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

2.4975,NiFeCr12Mo Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

2.4975,NiFeCr12Mo Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

2.4975(2.4662 ,NiFeCr12Mo) is is a nickel, iron, chromium super alloy which is hardened by aging with the addition of a considerable amount of molybdenum, titanium and aluminum elements. 2.4975(2.4662 ,NiFeCr12Mo) is a high performance material and the manufacturing route may include combinations of vacuum induction melting, vacuum arc remelting and ESR for the final application. 2.4975(2.4662 ,NiFeCr12Mo)is typically used for gas turbine engine discs, shafts, rings, housings and gaskets with a maximum service temperature of about 600 ° C. These are the areas of usage in general. The material has high yield strength and creep resistance at temperatures of 600 ° C. 2.4975(2.4662 ,NiFeCr12Mo) has a significant iron content, allowing it to combine strength with good forging properties.

Chemical composition of 2.4975(2.4662 ,NiFeCr12Mo, NiFeCr 12 Mo) forging turbine parts is as follows

C≤ 0.10

Si≤ 0.60

Mn≤ 2.00

P≤ 0.02

S≤ 0.01

Cr11.0 - 14.0

Mo5.00 - 7.00

Ni40.0 - 45.0

Ti2.35 - 3.10

Al≤ 0.35

Co≤ 1.00

Fe Rest

Heat treatment methods for 2.4975(2.4662 ,NiFeCr12Mo, NiFeCr 12 Mo) forged parts is as followinmg

it is a three-stage process involving a solution treatment followed by two age-hardening stages. The recommended procedure is 3h/1090°C (1994°F)/WQ +

4h/775°C (1427°F)/AC + 24h/705-720°C (1301-1328°F)/AC.

mechanical property of for 2.4975(2.4662 ,NiFeCr12Mo, NiFeCr 12 Mo) forged round bars is as follow

Mechanical properties of steel NiFeCr12Mo (2.4975)

Rm - Tensile strength (MPa) MIn 1180

Rp0.2 0.2% proof strength (MPa) Min 835

A - Min. elongation at fracture Min 15

Removal of test samples of 2.4975(2.4662 ,NiFeCr12Mo, NiFeCr 12 Mo) forged round bars

Unless otherwise indicated on the drawing or in the specification for the part , removal is to be effected as follows :

- longitudinal if the section can be inscribed in a circle with diameter < 1 0 0 mm

- transverse if the section can be inscribed in a circle with diameter ≥ 1 0 0 mm

- tangential for 2.4975(2.4662 ,NiFeCr12Mo) forged rings or disks

Number of tests of 2.4975(2.4662 ,NiFeCr12Mo, NiFeCr 12 Mo) forged parts. The following tests have to be carried out:

Chemical analysis: 1 for heat

HB hardness: 2 for bar, one on each end

Macrographic examination: 2 for bar, one on each end

Grain size: both ends of 1 bar from each lot

H.T. tensile strength: 1 for lot .

H.T. tensile strength: 1 for each temperature and lot, on mixed specimens (un-notched andnotched)

Welcome your inquiry of 2.4975(2.4662 ,NiFeCr12Mo, NiFeCr 12 Mo) forged parts