Description

Jiangsu Liangyi professional manufacturer of Refractaloy 26(R26,R-26,AISI 690,Z6NKCDT38,AMS 5760) open die forging parts and seamless rolled steel forged rings ,Refractaloy 26(R26,R-26) forged forging steam gas turbine blade vane bolts from china

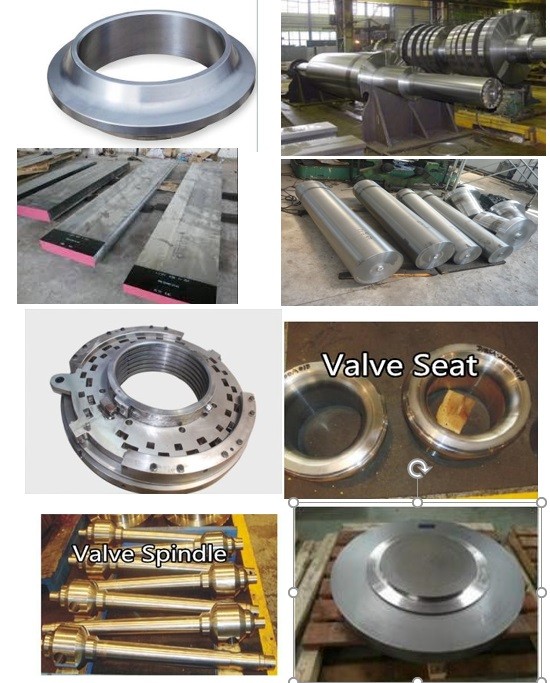

Following is the shape of Refractaloy 26(R26,R-26,AISI 690,Z6NKCDT38,AMS 5760)forging steel material that we could do is:Refractaloy 26 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,R-26 Forged forging steel rings seamless rolled rings,AMS 5760 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,Z6NKCDT38Forged Forging Steel Discs Disks Blocks plates,AISI 690 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of Refractaloy 26(R26,R-26,AISI 690,Z6NKCDT38,AMS 5760) material that is used in following industry

Refractaloy 26 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

R-26 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

R-26 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

Refractaloy 26 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

Refractaloy 26 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

Refractaloy 26 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

Z6NKCDT38 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

Refractaloy 26 is high heat resistant alloy of nickel, chromium, cobalt and iron, possessing high creep and endurance strengths along with high ductility at elevated temperatures. It responds to precipitation-hardening heat treatment. This datasheet provides information on composition, physical properties, hardness, and tensile properties as well as creep and fatigue.

The Refractaloy 26 forged material shall undergo the following heat treatment:

a)- SOLUTION TREATMENT of R26 forging parts

Holding temperature: 1025C - Holding tolerance: 2t 100C - Hoiding time (*): 12 h minimum Cooling means: oil or water

(*) Hoiding time shall be sufficient to insure complete recrystallization and the grain size specified

b)- 1st ageing at 815"C * 8C for 20 h minimum with cooling in fumace down to 730"C, followed by second ageing at 7300C t 8C for 20 h minimum and air cooling.

Chemicai composition of Refractaloy 26(R26,R-26,AISI 690,Z6NKCDT38,AMS 5760) forging turbine bolts steel

Ni=35,00- 39,00 %

Co=18,00 - 22,00 %

Cr=16,00- 20,00 %

Ti=2,50- 3,00 %

Mo =2,50 - 3,50 %0,001 -0,01 %

Si=1,50 % max

Mn =1,00%max

Al=0,25 % max

C=0,08 % max0,030 % max

S=0,030 % max

Fe=Balance

Chemical composition of R26 forging parts may be checked at our laboratory on residual crop ends from mechanical tests,that will be taken by our clients

Test specimen locations of R26 forging parts. All specimens shall be selected in mid-radius longitudinal direction or in thesemi-diagonal.

Lot definition. A lot is intended as being a group of bars from the same meit, having the same crosssection area, which have undergone together the same heat treatment, not exceeding 1.200 kg,

Number of tests of AISI 690 forged parts. The following tests have to be carried out:

Chemical analysis: 1 for heat

HB hardness: 2 for bar, one on each end

Macrographic examination: 2 for bar, one on each end

Grain size: both ends of 1 bar from each lot

H.T. tensile strength: 1 for lot .

H.T. tensile strength: 1 for each temperature and lot, on mixed specimens (un-notched andnotched)

Hardness test requirements:HB= 262- 331 HRC= 26- 35,5

Recuirements for R.T. tensile strength test for Refractaloy 26(R26,R-26) forged round bars :

Yield strength Min 550MPA

Tensile strength Min 1005

Elongation min 13%

Reduction Min 20

Requirements for H.I. tensile strength test for Refractaloy 26(R26,R-26) forged flat bars:

Test temperature at 565 drgree in stress of 610MM, minimum 100hours

Test temperature at 650 drgree in stress of 610MM, minimum 100hours

The elongation after rupture shall not be less than 5% when measured at room temperature.

Macrographic examination for Refractaloy 26(R26,R-26) forged rings

Two disks cutfrom the ends of each bar shall be etched for approximately 45 minutes with the following solution

- 80% HC1 (31%)

13% HF (52%)

7% HNO3 (69%)

After etching, the disks shall show a uniform structure and be free from non-metallic inclusions or other imperfections.

Grain size of Refractaloy 26(R26,R-26) forging turbine material

Following is the shape of Refractaloy 26(R26,R-26,AISI 690,Z6NKCDT38,AMS 5760)forging steel material that we could do is:Refractaloy 26 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,R-26 Forged forging steel rings seamless rolled rings,AMS 5760 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,Z6NKCDT38Forged Forging Steel Discs Disks Blocks plates,AISI 690 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of Refractaloy 26(R26,R-26,AISI 690,Z6NKCDT38,AMS 5760) material that is used in following industry

Refractaloy 26 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

R-26 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

R-26 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

Refractaloy 26 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

Refractaloy 26 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

AMS 5760 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case CasingsRefractaloy 26 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

Refractaloy 26 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

Z6NKCDT38 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

Refractaloy 26 is high heat resistant alloy of nickel, chromium, cobalt and iron, possessing high creep and endurance strengths along with high ductility at elevated temperatures. It responds to precipitation-hardening heat treatment. This datasheet provides information on composition, physical properties, hardness, and tensile properties as well as creep and fatigue.

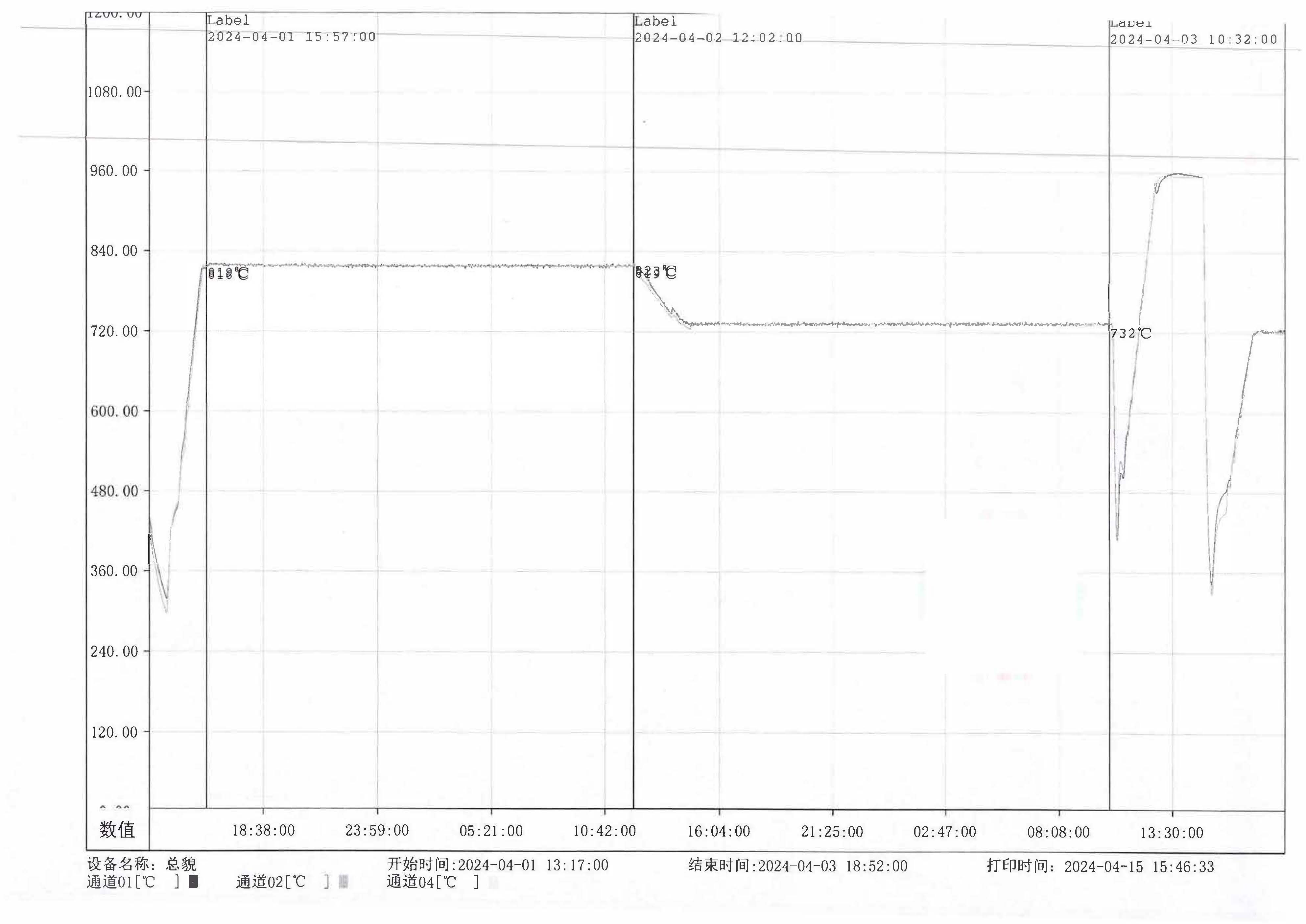

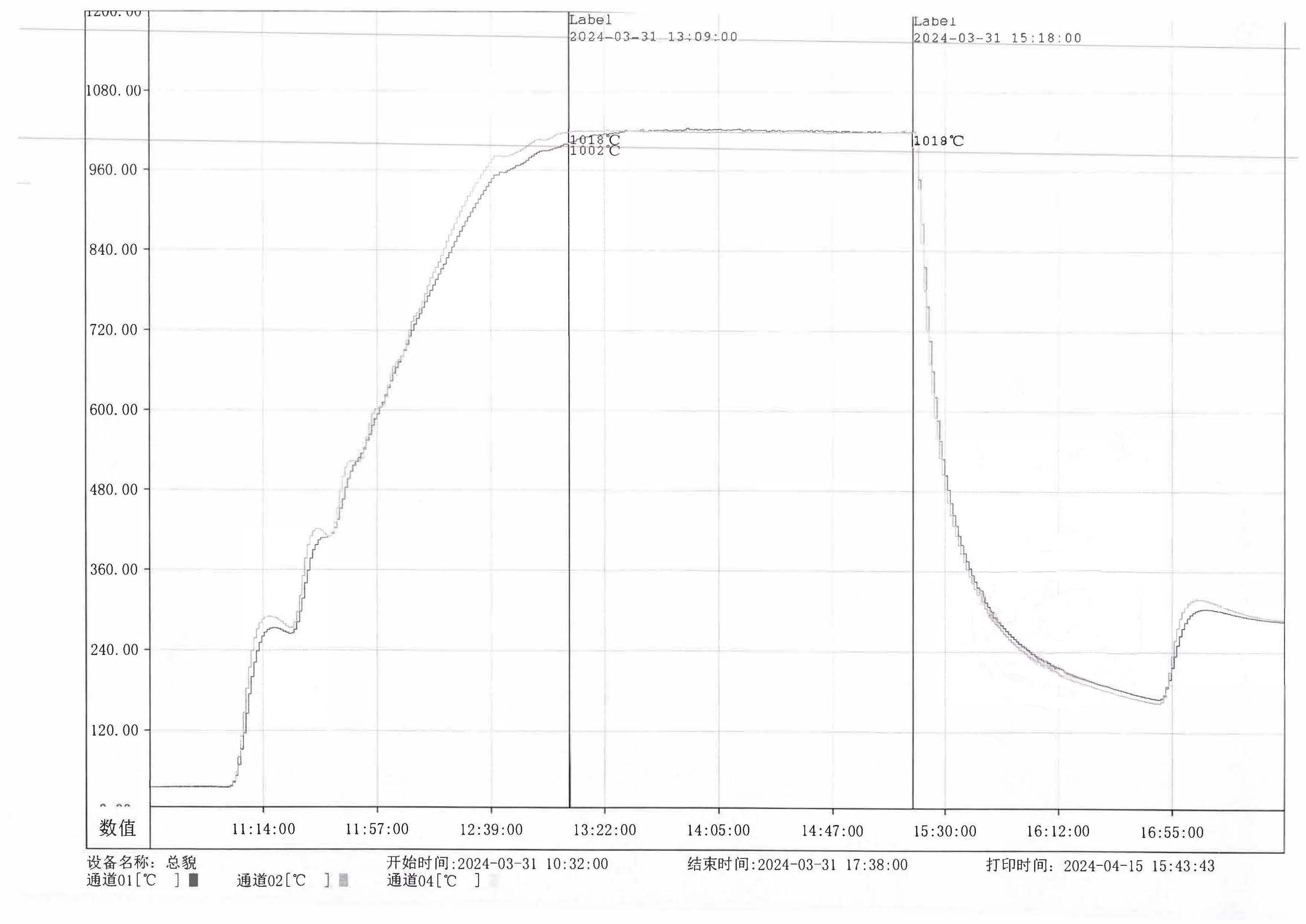

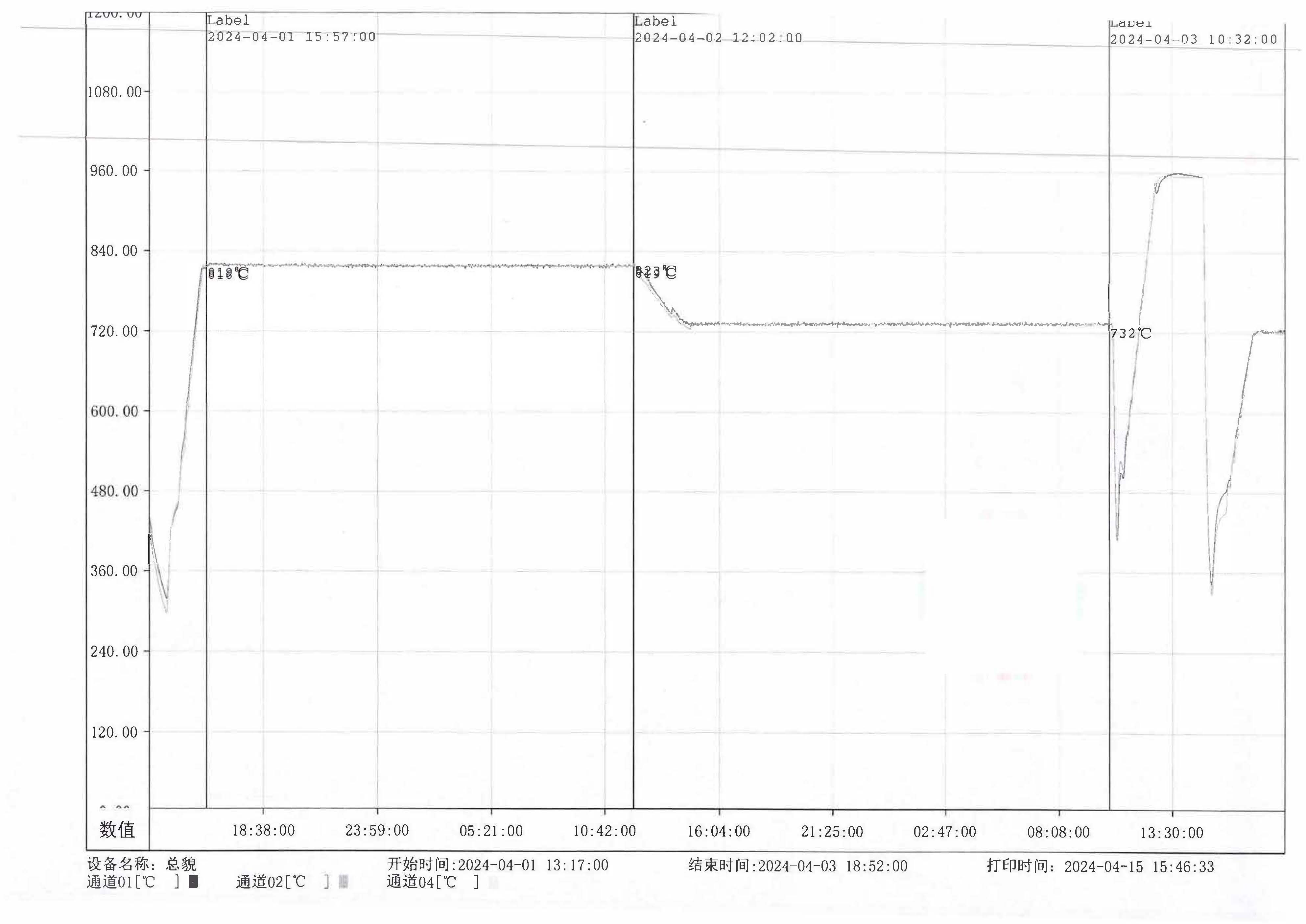

The Refractaloy 26 forged material shall undergo the following heat treatment:

a)- SOLUTION TREATMENT of R26 forging parts

Holding temperature: 1025C - Holding tolerance: 2t 100C - Hoiding time (*): 12 h minimum Cooling means: oil or water

(*) Hoiding time shall be sufficient to insure complete recrystallization and the grain size specified

b)- 1st ageing at 815"C * 8C for 20 h minimum with cooling in fumace down to 730"C, followed by second ageing at 7300C t 8C for 20 h minimum and air cooling.

All requirements specified in the following paragraphs shail be checked by our clients and possibly byour customer' s inspectors at our workshop

Following is heat treatment chart of R26 forging bars

Chemicai composition of Refractaloy 26(R26,R-26,AISI 690,Z6NKCDT38,AMS 5760) forging turbine bolts steel

Ni=35,00- 39,00 %

Co=18,00 - 22,00 %

Cr=16,00- 20,00 %

Ti=2,50- 3,00 %

Mo =2,50 - 3,50 %0,001 -0,01 %

Si=1,50 % max

Mn =1,00%max

Al=0,25 % max

C=0,08 % max0,030 % max

S=0,030 % max

Fe=Balance

Chemical composition of R26 forging parts may be checked at our laboratory on residual crop ends from mechanical tests,that will be taken by our clients

Test specimen locations of R26 forging parts. All specimens shall be selected in mid-radius longitudinal direction or in thesemi-diagonal.

Lot definition. A lot is intended as being a group of bars from the same meit, having the same crosssection area, which have undergone together the same heat treatment, not exceeding 1.200 kg,

Number of tests of AISI 690 forged parts. The following tests have to be carried out:

Chemical analysis: 1 for heat

HB hardness: 2 for bar, one on each end

Macrographic examination: 2 for bar, one on each end

Grain size: both ends of 1 bar from each lot

H.T. tensile strength: 1 for lot .

H.T. tensile strength: 1 for each temperature and lot, on mixed specimens (un-notched andnotched)

Hardness test requirements:HB= 262- 331 HRC= 26- 35,5

Recuirements for R.T. tensile strength test for Refractaloy 26(R26,R-26) forged round bars :

Yield strength Min 550MPA

Tensile strength Min 1005

Elongation min 13%

Reduction Min 20

Requirements for H.I. tensile strength test for Refractaloy 26(R26,R-26) forged flat bars:

Test temperature at 565 drgree in stress of 610MM, minimum 100hours

Test temperature at 650 drgree in stress of 610MM, minimum 100hours

The elongation after rupture shall not be less than 5% when measured at room temperature.

Macrographic examination for Refractaloy 26(R26,R-26) forged rings

Two disks cutfrom the ends of each bar shall be etched for approximately 45 minutes with the following solution

- 80% HC1 (31%)

13% HF (52%)

7% HNO3 (69%)

After etching, the disks shall show a uniform structure and be free from non-metallic inclusions or other imperfections.

Grain size of Refractaloy 26(R26,R-26) forging turbine material

It shall be at least 3 (in the rod centre, mid. radius and 3 mm from edge) according to UNI EN ISO 2624.

FOllowing is Metallographic Test Report of R26 forged rings

| Metallographic Test Report | |||||||||||||||||||||

| Report No: | JX20240415-4-4 | ||||||||||||||||||||

| R26 | 2221-582 | ||||||||||||||||||||

| Material Name | Heat No | ||||||||||||||||||||

| 15106FD REV-B | 241-091 | ||||||||||||||||||||

| Material Standard | HT No | ||||||||||||||||||||

| ASTM A604 | |||||||||||||||||||||

| Heat Treatment | Solution+Aging | Test Standard | |||||||||||||||||||

| Test data or result | |||||||||||||||||||||

|

|||||||||||||||||||||

| top | bottom | ||||||||||||||||||||

| Test location | Test direction | Etchant | |||||||||||||||||||

| The Cross section | Transverse | 80% volume HCL, 13% volume HF'7% volume HNO3 | |||||||||||||||||||

| Macro display: alloy intact, uniform structure, no harmful non-metallic inclusions and other harmful defects | |||||||||||||||||||||

| Metallographic Test Report | |||||||||||||||||||||

| Report No: | JX20240415-4-3 | ||||||||||||||||||||

| R26 | 2221-582 | ||||||||||||||||||||

| Material Name | Heat No | ||||||||||||||||||||

| 15106FD REV-B | 241-091 | ||||||||||||||||||||

| Material Standard | HT No | ||||||||||||||||||||

| ASTM E112 | |||||||||||||||||||||

| Heat Treatment | Solution+Aging | Test Standard | |||||||||||||||||||

| Test data or result | |||||||||||||||||||||

|

|||||||||||||||||||||

| 100X | 500X | ||||||||||||||||||||

| Test location | Test direction | Etchant | |||||||||||||||||||

| Center | 200ml Methanol,200mlHCL'10g | ||||||||||||||||||||

| Oriented longitudinally to the grain flow | CUCL2 | ||||||||||||||||||||

| 1.Grain Size: | Grade3.0 | ||||||||||||||||||||

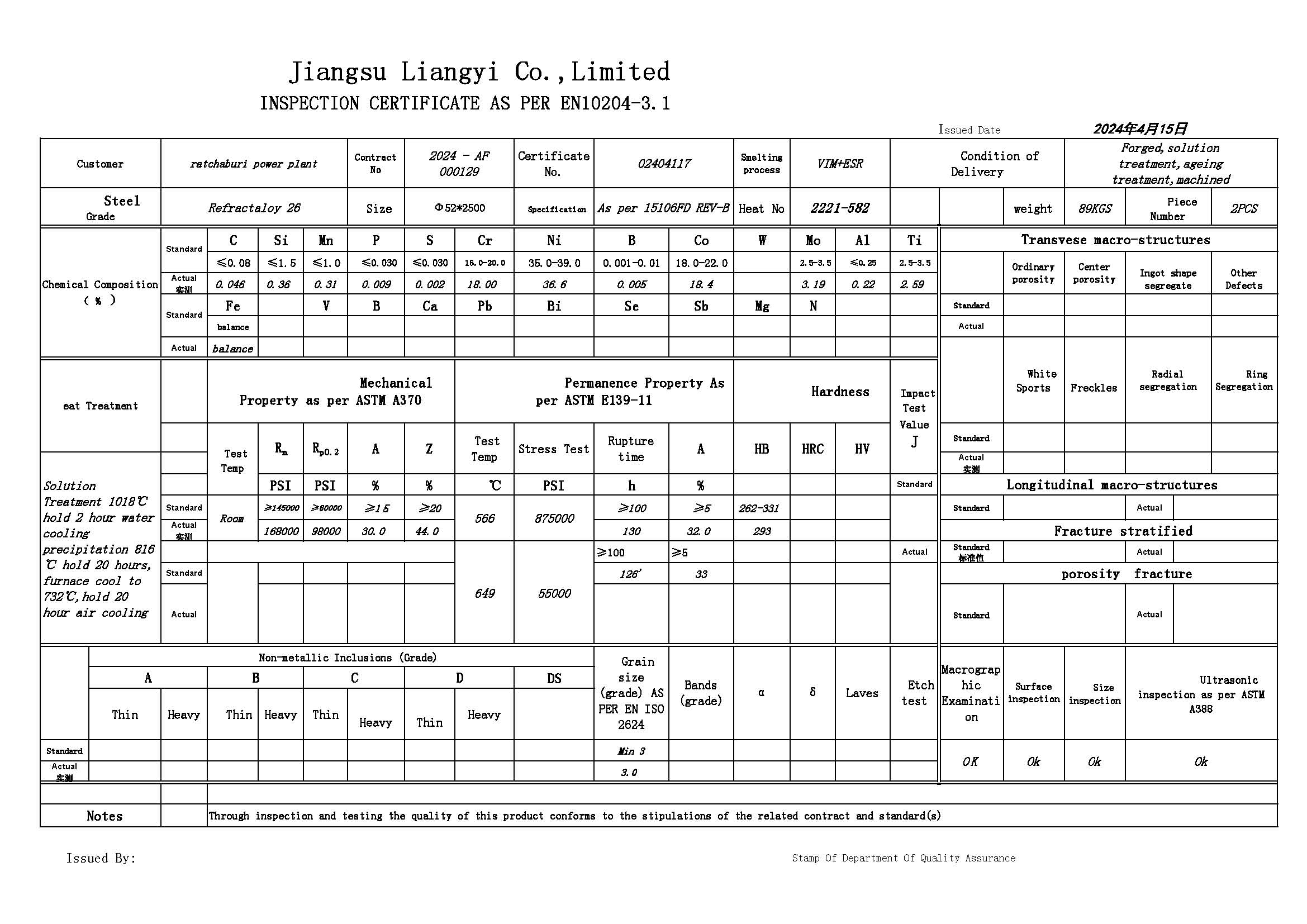

Following is one inspection certificate of Refractaloy 26 forged bars that we produce for our clients

Welcome your inquiry of Refractaloy 26(R26,R-26) forging parts