Description

Jiangsu Liangyi professional manufacturer of Z9CNA17-07,301S81,09KH17N7YU,09Х17Н7Ю,0Х17Н7Ю,Z9CNA17.07 open die forging parts and seamless rolled steel forged rings from china

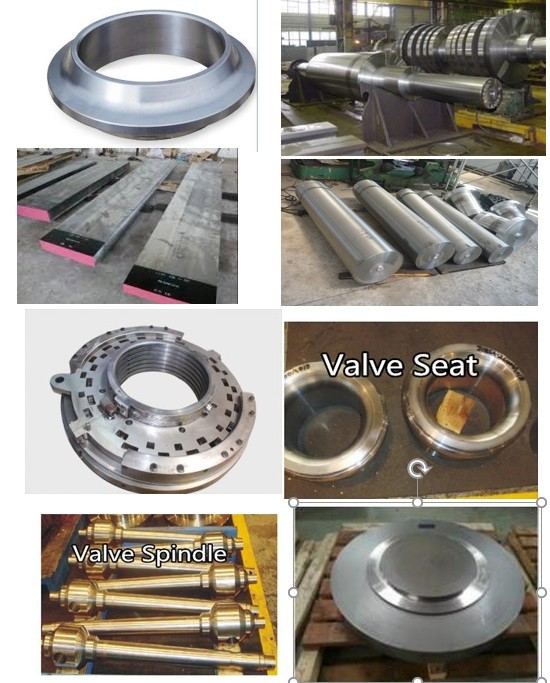

Following is the shape of Z9CNA17-07,301S81,09KH17N7YU,09Х17Н7Ю,0Х17Н7Ю,Z9CNA17.07 forging steel material that we could do is:Z9CNA17-07 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,301S81,Forged forging steel rings seamless rolled rings,09KH17N7YU Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,301S81 Forged Forging Steel Discs Disks Blocks plates,Z9CNA17.07 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of Z9CNA17-07,301S81,09KH17N7YU,09Х17Н7Ю,0Х17Н7Ю,Z9CNA17.07 material that is used in following industry

Z9CNA17-07 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

09KH17N7YU Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

Z9CNA17.07 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

301S81 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

Z9CNA17-07 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

301S81 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate pump

Z9CNA17.07Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

301S81 Forged Forging Marine Ship Boat Propeller Shafts

Z9CNA17-07 Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

Z9CNA17-07 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps con

Z9CNA17.07 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

Z9CNA17.07 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings

Z9CNA17-07(09KH17N7YU) is precipitation hardening stainless steel that provides high strength and hardness, excellent fatigue properties, good corrosion resistance, good formability, and minimum distortion upon heat treatment.

Z9CNA17-07(09KH17N7YU) provides valuable property combinations particularly well suited for aerospace applications. This special alloy also provides benefits for other applications requiring high strength and good corrosion resistance, as well as excellent properties for flat springs at temperatures up to 315°C (600°F ).

Z9CNA17-07(09KH17N7YU) stainless steel provides corrosion resistance is generally superior to that of the standard hardenable chromium types of stainless steels such as Types 410, 420 and 431, but is not quite as good as chromium-nickel Type 304.

FOllowing is chemical compostion of Z9CNA17-07,301S81,09KH17N7YU,09Х17Н7Ю,0Х17Н7Ю,Z9CNA17.07 forged steel sleeves

C max 0.09

Si max 0.8

Mn max 0.08

Ni 7 - 8

S max 0.02

P max 0.03

Cr 16 - 17.5

Al 0.5 - 0.8

Following of Z9CNA17-07(09KH17N7YU) forging parts mechnical property :

Rm - Tensile strength (MPa) (+AT) Min 830

Re-Yield strength (MPa) (+AT) MIn 735

A - Min. elongation at fracture (%) (+AT) 12

For melting Z9CNA17-07,301S81,09KH17N7YU,09Х17Н7Ю,0Х17Н7Ю,Z9CNA17.07 forging steel material, we have following melting equipment

60 t Electric Arc Furnace (EAF) / Power 40 MVA

2 Ladle Furnace (LF)

2 Tank Degassing VD - VOD type

Pits for bottom pouring

ESR Plant (max weight 32 t)

In order to make forging and make heat treatment Z9CNA17-07,301S81,09KH17N7YU,09Х17Н7Ю,0Х17Н7Ю,Z9CNA17.07 forging RIngs, we have following production equipment

Forging Process:3200/4200/6000 t Open die presses

Manipulators, Lifting Capacity up to 60 t

Heating Forging Furnaces, Max Capacity 150 t

Furnaces for Hydrogen Bake-Out Up to 14 m

Heat Treatment Semi-automatic Heat Treatment System Quality Heat Treatment

Furnaces Max lenght 18 m Quenching tanks up to 16 m

Welcome your inquiry of Z9CNA17-07,301S81,09KH17N7YU,09Х17Н7Ю,0Х17Н7Ю,Z9CNA17.07 forging forged steel parts

Following is the shape of Z9CNA17-07,301S81,09KH17N7YU,09Х17Н7Ю,0Х17Н7Ю,Z9CNA17.07 forging steel material that we could do is:Z9CNA17-07 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,301S81,Forged forging steel rings seamless rolled rings,09KH17N7YU Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,301S81 Forged Forging Steel Discs Disks Blocks plates,Z9CNA17.07 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of Z9CNA17-07,301S81,09KH17N7YU,09Х17Н7Ю,0Х17Н7Ю,Z9CNA17.07 material that is used in following industry

Z9CNA17-07 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

09KH17N7YU Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

Z9CNA17.07 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

301S81 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

Z9CNA17-07 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

301S81 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate pump

Z9CNA17.07Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

301S81 Forged Forging Marine Ship Boat Propeller Shafts

Z9CNA17-07 Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

Z9CNA17-07 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps con

Z9CNA17.07 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

Z9CNA17.07 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings

Z9CNA17-07(09KH17N7YU) is precipitation hardening stainless steel that provides high strength and hardness, excellent fatigue properties, good corrosion resistance, good formability, and minimum distortion upon heat treatment.

Z9CNA17-07(09KH17N7YU) provides valuable property combinations particularly well suited for aerospace applications. This special alloy also provides benefits for other applications requiring high strength and good corrosion resistance, as well as excellent properties for flat springs at temperatures up to 315°C (600°F ).

Z9CNA17-07(09KH17N7YU) stainless steel provides corrosion resistance is generally superior to that of the standard hardenable chromium types of stainless steels such as Types 410, 420 and 431, but is not quite as good as chromium-nickel Type 304.

FOllowing is chemical compostion of Z9CNA17-07,301S81,09KH17N7YU,09Х17Н7Ю,0Х17Н7Ю,Z9CNA17.07 forged steel sleeves

C max 0.09

Si max 0.8

Mn max 0.08

Ni 7 - 8

S max 0.02

P max 0.03

Cr 16 - 17.5

Al 0.5 - 0.8

Following of Z9CNA17-07(09KH17N7YU) forging parts mechnical property :

Rm - Tensile strength (MPa) (+AT) Min 830

Re-Yield strength (MPa) (+AT) MIn 735

A - Min. elongation at fracture (%) (+AT) 12

For melting Z9CNA17-07,301S81,09KH17N7YU,09Х17Н7Ю,0Х17Н7Ю,Z9CNA17.07 forging steel material, we have following melting equipment

60 t Electric Arc Furnace (EAF) / Power 40 MVA

2 Ladle Furnace (LF)

2 Tank Degassing VD - VOD type

Pits for bottom pouring

ESR Plant (max weight 32 t)

In order to make forging and make heat treatment Z9CNA17-07,301S81,09KH17N7YU,09Х17Н7Ю,0Х17Н7Ю,Z9CNA17.07 forging RIngs, we have following production equipment

Forging Process:3200/4200/6000 t Open die presses

Manipulators, Lifting Capacity up to 60 t

Heating Forging Furnaces, Max Capacity 150 t

Furnaces for Hydrogen Bake-Out Up to 14 m

Heat Treatment Semi-automatic Heat Treatment System Quality Heat Treatment

Furnaces Max lenght 18 m Quenching tanks up to 16 m

Welcome your inquiry of Z9CNA17-07,301S81,09KH17N7YU,09Х17Н7Ю,0Х17Н7Ю,Z9CNA17.07 forging forged steel parts