Description

Jiangsu Liangyi is professional manufacturer of 1.3817,X40MnCrN18 open die forging parts and seamless rolled steel forged rings from china

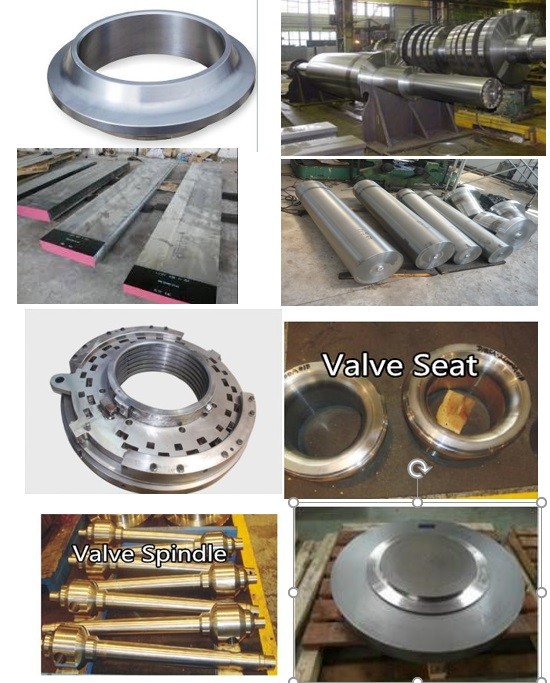

Following is the shape of 1.3817,X40MnCrN18 forging steel material that we could do is:X40MnCrN18 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,X40MnCrN18 Forged forging steel rings seamless rolled rings,1.3817 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,1.3817 Forged Forging Steel Discs Disks Blocks plates,X40MnCrN18 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 1.3817,X40MnCrN18 material that is used in following industry

X40MnCrN18 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

X40MnCrN18 forging forged steel turbine rotor shafts

X40MnCrN18 Forged Forging Steel Butterfly Valve Main Shafts Spindles

1.3817 Forged Forging ship boat Marine Propulsion Shafts Propeller Shaft

X40MnCrN18 Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

1.3817 Forged Forging venturi cone meter Body Bodies Blocks

1.3817 Forged Forging Steel gate valves Body Bodies bespoke flat bars

X40MnCrN18 forged steel Flowseal cryogenic High Performance BV Butterfly Valves HPBV shaft

X40MnCrN18 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

X40MnCrN18 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

X40MnCrN18 Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

X40MnCrN18 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

1.3817 Forged Forging forge Steel transition Cone

1.3817 Forged Forging Steel Pressure Vessel Reactor Nozzles

X40MnCrN18 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

FOllowing is melting methods of 1.3817 forged parts

1. Step 1- Basic EF

Step 2- Either Argon Oxygen Decarburization (AOD) or Vacuum Oxygen Decarburization (VOD) or Vacuum Degrassing.

Step 3- Either Electroslag Remelting (ESR) or Electroflux Remelting (EFR) or Vacuum Arc Remelting (VAR).

Optional Step 4- Vacuum Arc Remelting (VAR)

OR

2. Step 1- Vacuum Induction Melting (VIM)

Step 2- Either Electroslag Remelting (ESR) or Electroflux Remelting (EFR) or Vacuum Arc Remelting (VAR).

Optional Step 3- Vacuum Are Remelting (VAR).

FOllowing is chemical compostion of X40MnCrN18 forged steel rings

C: 0,30 - 0,50 %

Cr: 3,0 - 5,0%

Mn: 17,0 - 19,0 %

Ni: max. 1,0 %

S: max. 0,03 %

Si: max. 1,00 %

N: max. 0,1 % (Rest)

Following of X40MnCrN18 forging parts heat treatment mechanical property Delivery condition :

Rm - Tensile strength (MPa) (+AT) 750-950

Rp0.2 0.2% proof strength (MPa) (+AT) 280MPA

A - Min. elongation at fracture (%) longitud., (+AT) 35

Following is all testing report that we supply for 1.3817,X40MnCrN18 forged parts

1. Chemical composition The same furnace

2. Mechanical nature "The test which picks one set in the same furnace,the

same heat treatment,(The test piece extracts from

one in two)"

Hardness measurement All

4. Dimension inspection All

5. Appearance inspection All

6. Ultrasonic crack test All

7. Osmosis crack test All

8. Magnetic permeability Test All

Welcome your inquiry of 1.3817,X40MnCrN18 forging forged steel parts

Following is the shape of 1.3817,X40MnCrN18 forging steel material that we could do is:X40MnCrN18 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,X40MnCrN18 Forged forging steel rings seamless rolled rings,1.3817 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,1.3817 Forged Forging Steel Discs Disks Blocks plates,X40MnCrN18 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 1.3817,X40MnCrN18 material that is used in following industry

X40MnCrN18 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

X40MnCrN18 forging forged steel turbine rotor shafts

X40MnCrN18 Forged Forging Steel Butterfly Valve Main Shafts Spindles

1.3817 Forged Forging ship boat Marine Propulsion Shafts Propeller Shaft

X40MnCrN18 Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

1.3817 Forged Forging venturi cone meter Body Bodies Blocks

1.3817 Forged Forging Steel gate valves Body Bodies bespoke flat bars

X40MnCrN18 forged steel Flowseal cryogenic High Performance BV Butterfly Valves HPBV shaft

X40MnCrN18 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

X40MnCrN18 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

X40MnCrN18 Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

X40MnCrN18 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

1.3817 Forged Forging forge Steel transition Cone

1.3817 Forged Forging Steel Pressure Vessel Reactor Nozzles

X40MnCrN18 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

FOllowing is melting methods of 1.3817 forged parts

1. Step 1- Basic EF

Step 2- Either Argon Oxygen Decarburization (AOD) or Vacuum Oxygen Decarburization (VOD) or Vacuum Degrassing.

Step 3- Either Electroslag Remelting (ESR) or Electroflux Remelting (EFR) or Vacuum Arc Remelting (VAR).

Optional Step 4- Vacuum Arc Remelting (VAR)

OR

2. Step 1- Vacuum Induction Melting (VIM)

Step 2- Either Electroslag Remelting (ESR) or Electroflux Remelting (EFR) or Vacuum Arc Remelting (VAR).

Optional Step 3- Vacuum Are Remelting (VAR).

FOllowing is chemical compostion of X40MnCrN18 forged steel rings

C: 0,30 - 0,50 %

Cr: 3,0 - 5,0%

Mn: 17,0 - 19,0 %

Ni: max. 1,0 %

S: max. 0,03 %

Si: max. 1,00 %

N: max. 0,1 % (Rest)

Following of X40MnCrN18 forging parts heat treatment mechanical property Delivery condition :

Rm - Tensile strength (MPa) (+AT) 750-950

Rp0.2 0.2% proof strength (MPa) (+AT) 280MPA

A - Min. elongation at fracture (%) longitud., (+AT) 35

Following is all testing report that we supply for 1.3817,X40MnCrN18 forged parts

1. Chemical composition The same furnace

2. Mechanical nature "The test which picks one set in the same furnace,the

same heat treatment,(The test piece extracts from

one in two)"

Hardness measurement All

4. Dimension inspection All

5. Appearance inspection All

6. Ultrasonic crack test All

7. Osmosis crack test All

8. Magnetic permeability Test All

Welcome your inquiry of 1.3817,X40MnCrN18 forging forged steel parts