Description

Jiangsu Liangyi professional manufacturer of 1.4313(X3CrNiMo13-4,X 3CrNiMo 13-4,X3CrNiMo134,X3CrNiMo13.4)open die forging parts and seamless rolled steel forged rings from china

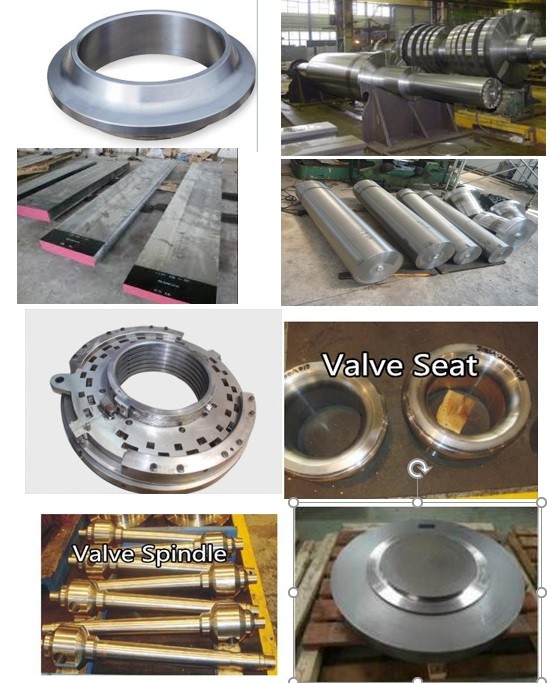

Following is the shape of 1.4313(X3CrNiMo13-4,X 3CrNiMo 13-4,X3CrNiMo134,X3CrNiMo13.4) forging steel material that we could do is:1.4313 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,X 3CrNiMo 13-4,Forged forging steel rings seamless rolled rings,X3CrNiMo13-4 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,X3CrNiMo134 Forged Forging Steel Discs Disks Blocks plates,X3CrNiMo13.4 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 1.4313(X3CrNiMo13-4,X 3CrNiMo 13-4,X3CrNiMo134,X3CrNiMo13.4) material that is used in following industry

1.4313 Forged Forging Steel Francis Hydro Power Hydraulic Turbine Generator Wicked Wicket Gate, Guide Vanes

X3CrNiMo13-4 forged steel hydropower pelton bucket Forged Forging Flat Steel Bars

X3CrNiMo13.4 Forged Forging Hydropower Francis Pelton Turbine runners,Turbine runners Discs Disks

X 3CrNiMo 13-4 Forged Forged Pumps suction side sealing jacket seal chambers jacket casings

X3CrNiMo134 Forged Forging Swivel Ring Flanges

X3CrNiMo13-4 Forging/Forged Forge Steel Wye Piece/Piggable Wyes

X3CrNiMo13.4 Forged Forging Swept branches outlets steel fittings swept saddles

1.4313 Forged Forging Steel double studded adapter flange

X3CrNiMo13.4 Forged Forging Steel Nuclear Power trunnions

1.4313 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

X3CrNiMo13-4 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

X3CrNiMo13.4 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

X3CrNiMo134 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

1.4313 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

X3CrNiMo134 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate pump

X3CrNiMo13.4Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

X3CrNiMo13-4 forged steel Mechanical Seal Discs

X3CrNiMo134 Forged Forging Marine Ship Boat Propeller Shafts

1.4313 Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

X3CrNiMo13-4 Forged Forging Gas Air Compressor Rotor

X3CrNiMo134 Forged Forging Steels Christmas Trees wellhead Spool Body Bodies cylinder

X3CrNiMo134 Forged Forging venturi cone meter Body Bodies Blocks

X3CrNiMo13.4 Forged Forging Steel frac pumps Fluid End Body Bodies Blocks Modules

1.4313 Forged Forging Steel gate valves Body Bodies bespoke flat bars

X3CrNiMo13-4 Forged Forging Steel drill head casings,collars,landing bowls

X3CrNiMo134 forging forged steel Couplings

X3CrNiMo13.4 forged steel Flowseal cryogenic High Performance BV Butterfly Valves HPBV shaft

X3CrNiMo13-4 forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

X3CrNiMo13.4 Forged Forging Steel Subsea X Tree high pressure elbow

X3CrNiMo134 forged forging Steel wellhead locknut Venturi Bench

1.4313 Forged Forging Steel double studded adapter flange

X3CrNiMo13-4 Forged Forging Steel integral Mud Flange Flanged outlet Studded crosses

X3CrNiMo134 forged steel Downhole drilling tool Mud Motor End Caps

X3CrNiMo13-4 Forged Forging Steel Casing Heads,Tubing Heads,Casing Hangers,Tubing Hangers,Tubing Spools,Casing Spools,Spacer Spools

1.4313 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

X3CrNiMo134 Forged Forging Steel Pressure Vessel STUDDING OUTLET

X3CrNiMo13.4 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

X3CrNiMo13-4 forging Forging/Forged Steel Wellhead Christmas Tree Frac Head (Fracturing Head)

X3CrNiMo134 Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

X3CrNiMo13.4 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings

X3CrNiMo13-4 Forged Forging forge Steel transition Cone

1.4313 Forged Forging Blowout Preventer RAM Annular dual Bops Body Bodies Block

FOllowing is production standard of 1.4313(X3CrNiMo13-4) forging steel parts

EN 10088-3: 2005 Stainless steels. Technical delivery conditions for semi-finished products, bars, rods, wire, sections and bright products of corrosion resisting steels for general purposes

EN 10028-7: 2007 Flat products made of steels for pressure purposes. Stainless steels

EN 10272: 2007 Stainless steel bars for pressure purposes

EN 10250-4: 2000 Open steel die forgings for general engineering purposes. Stainless steels

EN 10222-5: 2000 Steel forgings for pressure purposes. Martensitic, austenitic and austenitic-ferritic stainless steels

EN 10088-1: 2005 Stainless steels. List of stainless steels

1.4313(X3CrNiMo13-4) is a corrosion and acid resistant, soft martensitic chromium-nickel steel with added molybdenum.

The high toughness properties provide 1.4313 with excellent capabilities and increasing popularity. Valves, compressors, and centrifuges are typically made of this stainless steel.

Forged Steel 1.4313 - is primarily used in in chemical and petrochemical industries, engineering industry, pump industry and turbine wheels. Material 1.4313 is also used in power engineering in the valve construction. Use for instance valves, vanes, turbine blades, pump covers etc.

FOllowing is chemical compostion of 1.4313(X3CrNiMo13-4) forged steel sleeves

Iron (Fe) 78.5 to 84.2

Chromium (Cr) 12 to 14

Nickel (Ni) 3.5 to 4.5

Manganese (Mn) 0 to 1.5

Molybdenum (Mo) 0.3 to 0.7

Silicon (Si) 0 to 0.7

Carbon (C) 0 to 0.050

Phosphorus (P) 0 to 0.040

Nitrogen (N) 0 to 0.020

Sulfur (S) 0 to 0.015

Following of 1.4313(X3CrNiMo13-4) forging parts mechnical property :

Delivery condition +A: Tensile strength, Rm: <1100 MPa HBW Hardness: <320

Delivery condition +QT650 Tensile strength, Rm: 700 - 850 MPa Yield point, Re: >520 MPa Elongation, A: > 15% Impact resistance, KV: >70 J

Delivery condition +QT780 Tensile strength, Rm: 780 - 980 MPa Yield point, Re: >620 MPa Elongation, A: > 15% Impact resistance, KV: >70 J

Delivery condition +QT900 Tensile strength, Rm: 900 - 1100 MPa Yield point, Re: >800 MPa Elongation, A: >12% Impact resistance, KV: >50 J

Heat treatment of 1.4313 / X3CrNiMo13-4 forged steel parts is followings

1.4313(X3CrNiMo13-4) forged rings Delivery condition +A- Annealing at 600 - 650 ℃ with cooling in the air or with the furnace

1.4313(X3CrNiMo13-4) forging bars Delivery condition +QT650- Hardening at 950 - 1050 ℃ with cooling in oil or air, tempering at 650 - 700 ℃ + 600 - 620 ℃

1.4313(X3CrNiMo13-4) forging sleeves Delivery condition +QT780- Hardening at 950 - 1050 ℃ with cooling in oil or air, tempering at 550 - 600 ℃

1.4313(X3CrNiMo13-4) forging shafts Delivery condition +QT900- Hardening at 950 - 1050 ℃ with cooling in oil or air, tempering at 520 - 580 ℃ Forging and rollingat 1150 °C with cooling in the air

FOllowing is testing standard of our 1.4313 / X3CrNiMo13-4 forged steel parts

ASTM E10-12: Standard Test Method for Brinell hardness of Metallic Materials;

ASTM A370-12: Standard Test Methods and Definitions for Mechanical Testing of Steel Products;

ASTM E23-07a: Standard Test Methods for Notched Bar Impact Testing of Metallic Materials;

AMS 2315G: Determination of Delta Ferrite Content,

ASTM E45-05: Standard Test Methods for Determining the Inclusion Content of Steel,

ASTM E112-10: Standard Test Methods for Determining Average Grain Size,

ASTM E837: Standard Test Method for Determining Residual Stresses by the Hole-Drilling Strain-Gage Meth

Welcome your inquiry of 1.4313 / X3CrNiMo13-4 forging forged steel parts