Description

Jiangsu Liangyi professional manufacturer of 2.4650,NiCo20Cr20MoT open die forging parts and seamless rolled steel forged rings from china

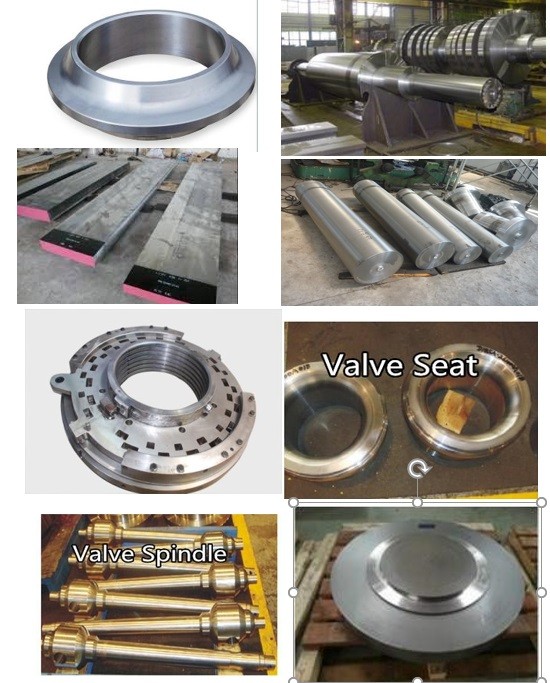

Following is the shape of 2.4650,NiCo20Cr20MoT forging steel material that we could do is: 2.4650 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,2.4650 Forged forging steel rings seamless rolled rings, 2.4650 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,NiCo20Cr20MoT Forged Forging Steel Discs Disks Blocks plates,2.4650 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 2.4650,NiCo20Cr20MoT material that is used in following industry

2.4650 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

NiCo20Cr20MoT Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

2.4650 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

NiCo20Cr20MoT Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

NiCo20Cr20MoT Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

2.4650 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

2.4650 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

2.4650,NiCo20Cr20MoT Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

2.4650,NiCo20Cr20MoT Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

2.4650 is a nickel, iron, chromium super alloy which is hardened by aging with the addition of a considerable amount of molybdenum, titanium and aluminum elements. 2.4650 is a high performance material and the manufacturing route may include combinations of vacuum induction melting, vacuum arc remelting and ESR for the final application. 2.4650 is typically used for gas turbine engine discs, shafts, rings, housings and gaskets with a maximum service temperature of about 600 ° C. These are the areas of usage in general. The material has high yield strength and creep resistance at temperatures of 600 ° C.

The following methods are admitted for melting 2.4650,NiCo20Cr20MoT forging parts :

- melting by electric air furnace with elaboration of alloy ( EAF & A OD or VO D ) or vacuum melting (VIM ) ;

- re melting under slag ( ES R ) or under vacuum ( VAR ) .

The 2.4650,NiCo20Cr20MoT forged material shall undergo the following heat treatment:

2.4650,NiCo20Cr20MoT can be solution annealed at 1149°C (2100°F) and rapidly cooled by using the water quench method. It can then be precipitation-hardened at 799°C (1470°F) for 24 h, which can be followed by air cooling.

Chemical composition of 2.4650,NiCo20Cr20MoT forging turbine parts is as follows

Nickel (Ni) 46.9 to 54.2

Chromium (Cr) 19 to 21

Cobalt (Co) 19 to 21

Molybdenum (Mo) 5.6 to 6.1

Titanium (Ti) 1.9 to 2.4

Aluminum (Al) 0.3 to 0.6

Iron (Fe) 0 to 0.7

Manganese (Mn) 0 to 0.6

Silicon (Si) 0 to 0.4

Copper (Cu) 0 to 0.2

Carbon (C) 0.040 to 0.080

Phosphorus (P) 0 to 0.020

Sulfur (S) 0 to 0.0070

Boron (B) 0 to 0.0050

mechanical property of for 2.4650,NiCo20Cr20MoT forged round bars is as follow

Rm - Tensile strength (MPa) (+P) 970

Rp0.2 0.2% proof strength (MPa) (+P) 570

A - Min. elongation at fracture (%) (+P) 30

Removal of test samples of 2.4650,NiCo20Cr20MoT forged round bars

Unless otherwise indicated on the drawing or in the specification for the part , removal is to be effected as follows :

- longitudinal if the section can be inscribed in a circle with diameter < 1 0 0 mm

- transverse if the section can be inscribed in a circle with diameter ≥ 1 0 0 mm

- tangential for 2.4650 forged rings or disks

For our finished production of 2.4650,NiCo20Cr20MoT forged steel bars should have following inspection report

Identification number, material number and designation, order number, drawing number,

Specification Number;

- Heat number, heat chemical analysis, melting method and product chemical analysis;

- Certificate of heat treatment including method of cooling, actual part temperature, holding

time, cooling condition and all re-heat-treatments by complete graphic temperature time;

- Nondestructive testing records,

- Results of all Mechanical Tests,

-Results of residual stress measurements (for process qualification),

- All probable deviation reports,

- Certification of NDT inspector,

- Dimensional and visual inspection report,

- Cleaning Verified

Welcome your inquiry of 2.4650,NiCo20Cr20MoT forging parts