Description

Jiangsu Liangyi is professional manufacturer of Nimonic ALloy 901,Incoloy 901, Nimonic 901, ALloy 901,UNS N09901,Nickel Alloy 901 open die forging parts and seamless rolled steel forged rings from china

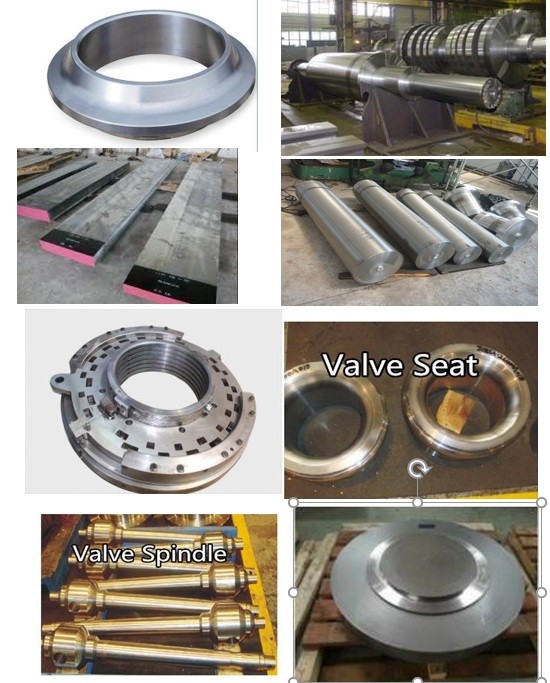

Following is the shape of Nimonic ALloy 901,Incoloy 901, Nimonic 901, ALloy 901,UNS N09901,Nickel Alloy 901 forging steel material that we could do is:Nimonic 901 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Nimonic ALloy 901 Forged forging steel rings seamless rolled rings,Nimonic 901 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,UNS N09901 Forged Forging Steel Discs Disks Blocks plates,ALloy 901 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of Nimonic ALloy 901,Incoloy 901, Nimonic 901, ALloy 901,UNS N09901,Nickel Alloy 901 material that is used in following industry

Nimonic ALloy 901 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

Nimonic 901 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

ALloy 901 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

UNS N09901 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

ALloy 901 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

Incoloy 901 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

Nimonic 901 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

ALloy 901 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

Incoloy 901 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

Nimonic 901 forged material for nuclear power such as :Flow limiter Venturi forgings (steam generator),Forged tubes for pressurizer surge line,reactor nozzles and primary pump fly wheels, divider plates for steam generator,Latch housings, rod travel housings and funnel extension,end ring and rotor stack plate forgings,bearing housings and stator end cap and closure ring forgings,Containment plates, rings and closure heads,Waste Flasks and Mounting Skirt,RPV Upper Shell and HSG Shell,Shell Strakes and Transition Cones,Pressure Components,Lifting Pin Tools and Trunnions,Pressuriser Upper Head and Upper Shell,Steam Drumhead and Lifting Pintles

NIMONIC Alloy 901 is an age-hardenable super alloy which contains Titanium and Aluminium for precipitation hardening and molybdenum for soild-solution strengthening. Alloy 901 has high yield strength and creep resistance at temperatures to about 1110°F (600°C). As Alloy 901 has a substantial iron content it enables alloy 901 to combine strength with good forging characteristics. Alloy 901 is commonly used for gas turbine engine discs, shafts, rings, casings and seals.

FOllowing is inspection standard of Nimonic ALloy 901,Incoloy 901, Nimonic 901, ALloy 901,UNS N09901,Nickel Alloy 901 Forged steel material

ASTM E 8 Tension Testing of Metallic Materials

ASTM E 8M Tension Testing of Metallic Materials (Metric)

ASTM E 10 Brinell Hardness of Metallic Materials

ASTME 139 Conducting Creep, Creep-Rupture, and Stress-Rupture Tests of Metallic Materials

ASTM E 292 Conducting Time-for-Rupture Notch Tension Tests of Materials

ASTM E 354 Chemical Analysis of High-Temperature, Electrical, Magnetic, and Other Similar lron, Nickel, and Cobalt Alloys

Composition Element of Nimonic ALloy 901,Incoloy 901, Nimonic 901, ALloy 901,UNS N09901,Nickel Alloy 901 forged steel turbine parts is as followings

Carbon: max 0.10

Manganese: max 1.00

Silicon: max 0.60

Phosphorus : max 0.030

Sulfur: max 0.030

Chromium: 11.00-14.00

Nickel: 40.00-45.00

Molybdenum: 5.00-7.00

Titanium: 2.35-3.10

Boron: 0.01 0-0.020

Cobalt: max 1.00

Aluminum: max0.35

Copper: max0.50

Lead: max0.0005(5ppm)

Bismuth: max0.00003 (0.3 ppm)

Selenium: max0.0003 (3ppm)

Iron: remainder

Check Analysis of Nimonic 901 forged parts: Composition variations shall meet the requirements of AMS 2269; no variationover maximum is permitted for lead, bismuth, and selenium.

Incoloy 901 forged material shall be multiple melted using consumable electrode practice in the remelt cycle or shall beinduction melted under vacuum. If consumable electrode remelting is not performed in vacuum,electrodes which have been produced by vacuum induction melting shall be used for remelting.

All our Alloy 901 forged bars shall be solution, stabilization, and precipitation heat treated as follows;property shall be in accordance with AMS 2750. FOllowing is heat treatment way:

Solution Heat Treatment: Heat to a temperature within the range 1975 to 2025 ·F (1079 to 1107 C), hold at the selected temperature within t25 ·F (t14 C) for 2 hours t 0.25,and cool at a rate equivalent to an air cool or faster.

Stabilization Heat Treatment: Heat to a temperature within the range 1425 to 1475 ·F(774 to 802 *C), hold at the selected temperature within t15 *F (t8 C) for 2 to 4 hours, andcool at a rate equivalent to an air cool or faster.

Precipitation Heat Treatment: Heat to a temperature within the range 1325 to 1375 ·F(R)(718 to 746 ·C), hold at the selected temperature within t15 ·F (t8 C) for 24 hourst 1, and cool at any convenient rate.

Tensile Propertiesis determined in accordance with ASTME 8 or ASTM E 8M; requirements apply in both the longitudinal and transverse directions but tests in the transverse direction need be made only on product from which a specimen not less than 2.50 inches (63.5 mm) in length can be taken. Tests in the longitudinal direction are notrequired on product tested in the transverse direction.

Mechanical property of Nimonic ALloy 901,Incoloy 901, Nimonic 901, ALloy 901,UNS N09901,Nickel Alloy 901forged ring is as followings:

Tensile Strength:Min150 Ksi (1034 MPa)

Yield Strength at 0.2% Offset Min100 ksi ( 689 MPa)

Elongation in 4D:min 12%

Reduction of Area:Min 15%

Hardness: Shall be 302 to 388 HB,

Stress-Rupture test of Nimonic ALloy 901 forged round bars is as following:

Stress-Rupture Properties at 1200 ·F (649 "C): Shall be as follows; testing of notched specimens and of combination smooth-and-notched specimens shall be performed in accordance with ASTM E 292 and of smooth specimens in accordance with ASTM E 139:

A standard cylindrical combination smooth-and-notched specimen conforming to ASTM E 292, maintained at 1200 ·F t 3 (649 *C t 2) while a load sufficient to produce aninitial axial stress of 80.0 ksi (552 MPa) or higher is applied continuously, shall not rupture inless than 23 hours. The test shall be continued to rupture without change of load. After the23 hours, if rupture occurs in the notch, the smooth section shal, by suitable means, be continued to rupture or a separate smooth specimen shalli be tested to rupture. Elongationof the smooth section after rupture, measured at room temperature, shall be not less than5% in 4D.

As an alternate procedure, separate smooth and notched specimens, machined from adjacent sections of the same piece, with gage sections conforming to the respectivedimensions shown in ASTM E 292, may be tested individually uThe smooth specimen shall not rupture in less than 23 hours and elongation afterrupture, measured at room temperature, shall be not less than 5% in 4D. The notched specimen shall not rupture in less than 23 hours but need not be tested to rupture, the load required to produce an initial axial stress of 80.0 ksi (552 MPa) or highershall be used to rupture or for 23 hours, whichever occurs tirst. After the 23 hours and atintervals of 8 to 16 hours, preferably 8 to 10 hours, thereafter, the stress shall be increasedin increments of 5.0 ksi (34.5 MPa). Time to rupture, rupture location, and elongation requirements shall be as specified

Welcome your inquiry of Nimonic ALloy 901,Incoloy 901, Nimonic 901, ALloy 901,UNS N09901,Nickel Alloy 901 forged parts