Description

Jiangsu Liangyi professional manufacturer of 1.6931(26NiCrMoV8-5.26NiCrMoV8.5,26NiCrMoV85,26 NiCrMoV 8 5) open die forging parts and seamless rolled rings,,turbo generator,Turbomachines,Turbomachinery,turbogenerator forging steel shafts , and 26NiCrMoV8-5 forged steel Gas steam turbine high pressure and intermediate pressure rotors, monobloc rotors, shaft ends, hollow shafts factory from china

1.6931 26NiCrMoV85 is steel as per standard of SEW 555 (1984) Steels for larger forgings for components in turbine and generator production, such as turbine bolts, turbine rotor shafts, turbine blades and so on

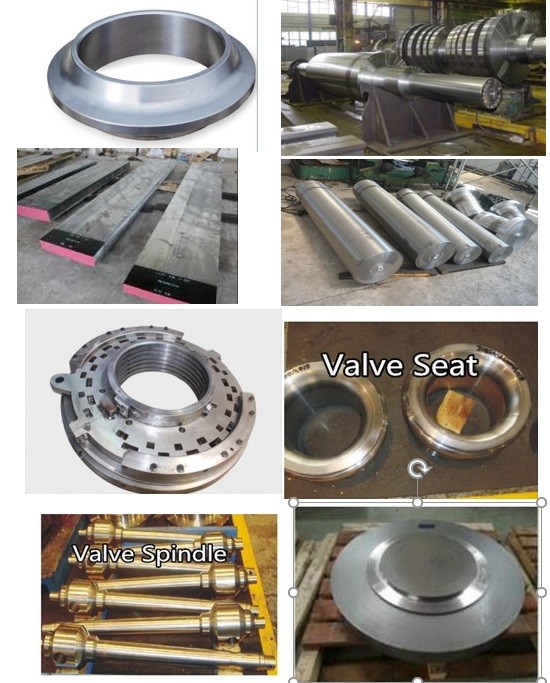

Following is the shape of 1.6931(26NiCrMoV8-5.26NiCrMoV8.5,26NiCrMoV85,26 NiCrMoV 8 5) forging steel material that we could do is:26NiCrMoV8-5 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,26NiCrMoV8.5 Forged forging steel rings seamless rolled rings, 26 NiCrMoV 8 5 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,26NiCrMoV85 Forged Forging Steel Discs Disks Blocks plates, 1.6931 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.26NiCrMoV8-5 Forged Forging Steel Gas Steam Turbine Rotors Shafts,1.6931 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars,26NiCrMoV85 Forged Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings,,26NiCrMoV8.5 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,26NiCrMoV85 Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

Carbon (C%):Min: 0,22 Max: 0,32

Manganese (Mn%):Min: 0,15 Max: 0,40

Silicon (Si%):≤ 0,30

Phosphorus (P%):≤ 0,015

Sulfur (S%):≤ 0.018

Chrome (Cr%)Min: 1,00 Max: 1,50

Nickel (Ni%):Min: 1,80 Max: 2,10

Molybdenum (Mo%):Min: 0,25 Max: 0,45

Vanadium (V%):Min: 0,05 Max: 0,15

All our 26NiCrMo85 forged steam turbine rotor shafts shall be TEMPER ANNEALING T0 REDUCE 0F INTERNAL STRESSFORGING SUPPLY MACHINED IN REQUIRED TOLERANCE

MECHANICAL PROPERTIES Of 26NiCrMo8-5 forged turbine blade steel is as follows

MIN. YIELD strength:Min 590MPA

TENSIL STRENGT:686-834 MPa

LONGITUDINAL ELONGATION Min20 %

TANGENTIAL ELONGATION Min18 %

LONGITUDINAL NOTCH Toughness Min 78J/cm2

TANGENTIAL NOTCH Toughness..Min 59 J/cm2

FOllowing is 1.6931 forged steel all testing that we will do

MATERIAL TESTS of 26NiCrMo8-5 forging turbine blade steel

CHEMIST test of 26NiCrMo85 forging parts

MATERIAL FOR TESTS REMOVE FROM ADDENDUM FOR TESTS

3X TENSION TEST ACC. T0 EN ISO 6892- -1 of 26NiCrMo8-5 forging material

3X NOTCH TOUGNESS TEST ACC. T0 IS0 148-1 of 26NiCrMo85 forged rings

UL TRASONIC DETECTION WLL BE MAKED ON THE MACHINED FORGING ACC.T0 CSN EN 10228- -3, QUALITY CLASS 3 for all 1.6931 forgings

RANGE 0F ULTRASONIC TESTS:

- BY A DIRECTLY PROBE IN THE RANGE OF 100%(360") FROM THE ROLLED SURFACEAND FROM THE FRONT SURFACES

- BY AN ANGLE PROBE FOR LONGITUDINAL AND TRANSVERSE DEFECTS

IN THE RANGE OF 100%(360") FROM THE ROLLED SURFACE

BY A DOUBLE-PROBE IN THE AREA UNDER THE TEST SURFACE WHERE IT IS NOT POSSIBLT0 CARRY OUT EVALUATION 0F DEFECTS BY THE DIRECT PROBE TEST

REGISTRATION LEVEL:

FOR THE DIRECT AND DOUBLE-PROBES ACCORDING T0 TB...SRR = 3mm

DECREASE OF END ECHO.... = 0.5

- FOR THE DOUBLE-PROBES ACCORDING T0 TAB.... = 3mm

- FOR ANGLE PROBES ACCORDING TO T......... = 3mm

MICRO-CL .EANLINESS ANALYSIS D/4 ACC. T0 DIN 50602 K4 - 6x SIMPLEACCEPTANCE: K4 < 10 for all 26NiCrMo8-5 forging turbine rotor shafts material

LATERAL ETCHING TEST FOR MACROSTRUCTURE ACC. TO ASTM E381 of all turbine 26NiCrMo85 forging steel

ACCEPTANCE: C1, S1, R1

EVAL UATION CROSS- SECTION OF AUSTENITIC GRAIN ACC. TO ASTM E112 for all turbine forged steel

ACCEPTANCE: > 6

EVALUATION MICROSTRUCTURE (ACC. T0 HEAT TREATMENT) + F0T0

DIMENSIONS AND TOL ERANCES OF FORGING ARE T0 BE ACCORDING THE DRAWNGALLOWANCE FOR TESTS DEVIDE FROM FORGING AFTER HEAT TREATMENT

SMELTING No., MATERIAL No., DRAWING No. AND SUPERVISION No for all 1.6931 forged material

IMPRINT TO FRONT OF THE FORGING

TEST RESULTS ARE T0 BE STATED IN A CERTIFICATE 3.1 ACC. TO EN 10204 IN LANGUAGE VERSION MEN TIONEDS IN ORDER

ACCEPTANCE 0F FORGING ACC. T0 CSN 420276.64 EN 10250-1-2 for all 26NiCrMo85 turbine rotor shafts material

Welcome your inquiry of 1.6931(26NiCrMoV8-5.26NiCrMoV8.5,26NiCrMoV85,26 NiCrMoV 8 5) forging forged steel parts