Description

Jiangsu Liangyi professional manufacturer of 20CDV5-07,20 CDV 5-07,20CDV5.07,20CDV507 open die forging parts and seamless rolled steel forged rings,forged pipes tubes,20CDV5-07 forging steel gears,pinion shafts,gear shafts, spindles,20CDV5.07 forged forging steel gas steam turbine blade bolts rotor shafts from china

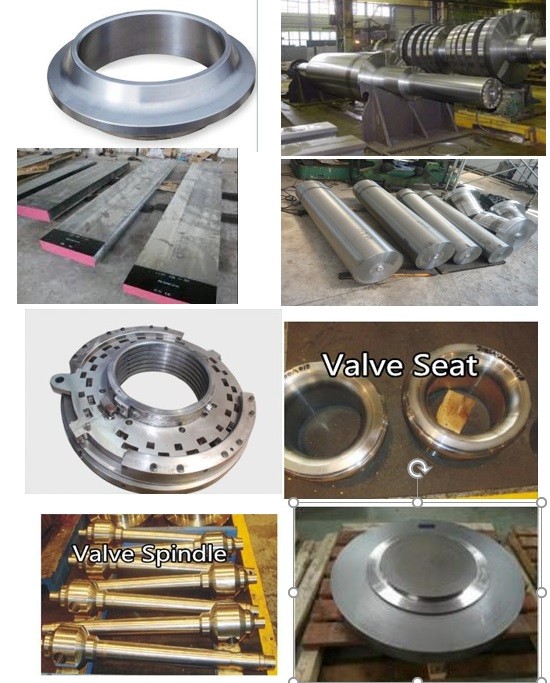

Following is the shape of 20CDV5-07,20 CDV 5-07,20CDV5.07,20CDV507 forging steel material that we could do is:20CDV5-07 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,20CDV5.07 Forged forging steel rings seamless rolled rings,20CDV507 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,20 CDV 5-07 Forged Forging Steel Discs Disks Blocks plates,20CDV5.07 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 20CDV5-07 that is used in following industry

20CDV5-07 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

20 CDV507 Forged Forging Gas steam turbine rotor shafts

20 CDV 5-07 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs, turbine wheels

20CDV5-07 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

20CDV5.07 forged forging steel gear, gear shafts,spindle, pinion shafts

20CDV5.07 is high temperature boiler steels for energy industries. They are used in the production of components/subassemblies for the power industry, working at the temperatures up to 550 oC for small parts and for large forgings. The main applications of these grades of steel are rotors of steam turbines, rotor blades, shaft forgings, reservoirs and covers for up to 550 ℃ temperatures, nuts, tubes for high temperatures up to 540 ℃.

For melting 20CDV5-07,20 CDV 5-07 forged steel parts, we have following melting equipment

60 t Electric Arc Furnace (EAF) / Power 40 MVA

2 Ladle Furnace (LF)

2 Tank Degassing VD - VOD type

Pits for bottom pouring

ESR Plant (max weight 32 t)

FOllowing is chemical compostion of 20CDV5.07 forged steel parts

Carbon:0.17 -0.24

Silicon :0.5 max

Manganese :0.30- 0.60

Chromium :1.10 -1.50

Nickel :0.50 max

Molybdenum :0.50- 0.8

Phosphorus: 0.035 max

Sulphur: 0.035 max

Vanadium :0.15 - 0.35

FOllowing is mechanical property of 20CDV5-07 forged steel turbine bolts

Rm - Tensile strength (MPa) (+QT) 700-850

Rp0.2 0.2% proof strength (MPa) (+QT)MIn 550

KV - Impact energy (J) (+QT) +20° min 63

A - Min. elongation at fracture (%) (+QT) Min 16

Z - Reduction in cross section on fracture (%) (+QT) Min 60

Brinell hardness (HBW): (+AC) 229

Brinell hardness (HBW): (+S) 255

All our finish production of 20CDV5-07 forged steel material should will done in Following NDE shall be performed in delivery condition:

- Visual inspection

Material verification test

- 100% UT- inspection according to EN 10228-3 (table 3). Depending on the forging geometry,

following inspection types are applicable:

- for 20CDV5-07 forging bar shape components; type 1 (inspection may also be carried out as per EN10308 for type 1)

- for 20CDV507 forged discs and plate- like components: type 2

- for 20CDV5-07 forging ring or bushing- like components: type 3b and 3

Welcome your inquiry of 20CDV5-07,20 CDV 5-07 forging forged steel parts