Description

Jiangsu Liangyi professional manufacturer of 20Х11МНФ(20Ch11MNF,20Х12МНФ-Ш ,20Ch12MNF) open die forging parts and forged steel gas steam turbine turbine blade vane steel ,turbo generator,Turbomachines,Turbomachinery,turbogenerator forging steel turbine rotor shafts, boiler forged tubes pipes shells case factory from china

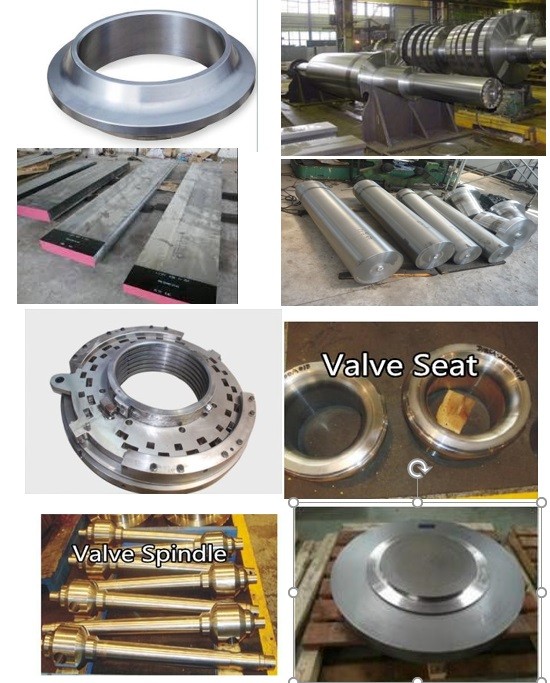

Following is the shape of 20Х11МНФ(20Ch11MNF,20Х12МНФ-Ш ,20Ch12MNF) Forging steel material that we could do is:20Х11МНФ Forged Steel round bars square bars Flat bars Rectangles Bars Rods, 20Ch11MNF Forged forging steel rings seamless rolled rings, 20Х12МНФ-Ш Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,20Ch12MNF Forged Forging Steel Discs Disks Blocks plates, 20Ch11MNF Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings. 20Ch12MNF Forged Forging Steel Gas Steam Turbine Rotors Shafts,20Х12МНФ-Ш Forged Forging Gas Compressor Turbine Blades turbine Vane steel Flat Rectangles Bars, 20Ch12MNF Forged Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings,,20Х11МНФ Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,20Х12МНФ-Ш Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

20Х11МНФ(20Ch11MNF,20Х12МНФ-Ш ,20Ch12MNF) is Corrosion resistant high temperature martensitic steel for power engineering, turbine blades, bolts and nuts

Following is melting methods of 20Х11МНФ(20Ch11MNF,20Х12МНФ-Ш ,20Ch12MNF) forging steel parts

Vacuum degassed steel with low silicon content (e.g.VCD steel) or remelted steel shall be used and shall be thoroughly forged. The use of any other secondary steel treatment (e. g. CAB) shall be agreed upon in advance with the purchaser in each individual case.

Chemical composition for 20Х11МНФ(20Ch11MNF,20Х12МНФ-Ш ,20Ch12MNF) forged steel gas turbine blade steel as follows

(C): 0,15 - 0,21

(Si): до 0,6

(Mn): 0,6 - 1

(Ni): 0,5 -1

(S): до 0,025

(P): до 0,03

(Cr): 10 - 11,5

(Mo): 0,8 - 1,1

(V): 0,2 - 0,4

(Nb): 0,2 - 0,45

The following properties of 20Х11МНФ(20Ch11MNF,20Х12МНФ-Ш ,20Ch12MNF) forging turbine blade flat bars at room temperature must be demonstrated by the following tests

Tensile strength, Rm: 690 - 840 MPa

The yield point, Rp0,2: >490 MPa Properties of samples tested

longitudinally: Elongation, A:> 17%

Impact resistance, KV20℃: > 20 J

Properties of samples tested transversally:

Elongation, A:> 14%

Impact resistance, KV20℃: > 20 J

20Х11МНФ(20Ch11MNF,20Х12МНФ-Ш ,20Ch12MNF) forging steel parts at elevated temperatures - the yield point is as follows

Temperature 200℃ - Rp0,2: >430 MPa

Temperature 250-205℃ - Rp0,2: >415 MPa

Temperature 300℃ - Rp0,2: >390 MPa

Temperature 350℃ - Rp0,2: >380 MPa

Temperature 400℃ - Rp0,2: >360 MPa

Temperature 450℃ - Rp0,2: >330 MPa

Temperature 500℃ - Rp0,2: >290 MPa

Temperature 550℃ - Rp0,2: >250 MPa

All our forged 20Х11МНФ(20Ch11MNF,20Х12МНФ-Ш ,20Ch12MNF) forged gas turbineparts can be release en10204-3.1 certificate, or en10204-3.2 inspection certificate from following third party,3.2 mit TUV ,GL BV,DNV,ABS ,Lloyds Register of Shipping, RMRS ,RINA and so on