Description

Jiangsu Liangyi professional manufacturer of X18CrMnMoNbVN12, 1.4916 open die forging parts and forged steel gas steam turbine turbine blade vane steel factory from china

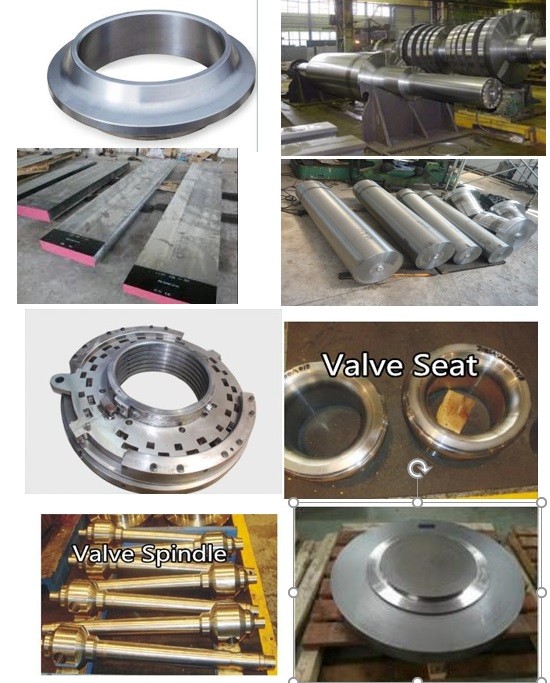

Following is the shape of X18CrMnMoNbVN12,1.4916 Forging steel material that we could do is:19CrMoVNbN11-1 Forged Steel round bars square bars Flat bars Rectangles Bars Rods, X18CrMnMoNbVN12 Forged forging steel rings seamless rolled rings, 1.4916 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,X18CrMnMoNbVN12 Forged Forging Steel Discs Disks Blocks plates, 1.4916 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.X18CrMnMoNbVN12 Forged Forging Steel Gas Steam Turbine Rotors Shafts,X18CrMnMoNbVN12 Forged Forging Gas Compressor Turbine Blades turbine Vane steel Flat Rectangles Bars, 1.4916 Forged Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings,,X18CrMnMoNbVN12 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,1.4916 Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

Chemical composition for X18CrMnMoNbVN12 forged steel gas turbine blade steel as follows

Carbon (C%) Min: 0,15 Max: 0,20

Manganese (Mn%) Min: 0,50 Max: 1,00

Silicon (Si%) ≤ 0,50

Phosphorus (P%) ≤ 0,04

Sulfur (S%) ≤ 0,03

Chrome (Cr%)Min: 10,0 Max: 13,0

Nickel (Ni%) Max: 0,60

Molybdenum (Mo%)Min: 0,30 Max: 0,90

Vanadium (V%) Min: 0,10 Max: 0,40

Niobium (Nb%) Min: 0,20 Max: 0,60

Nitrogen (N%)Min: 0,05 Max: 0,10

The mechanical properties X18CrMnMoNbVN12 forging round bars shall be determined after all heat treatment steps are finished(including a possible stress relieving). They shall be determined on the hardest and softestbar per melt and heat treatment batch. If the cross section are > 200cm? then the mechanicalproperties must be determined both in the centre of the bar and at the side of the bar(attachment 2). It shall be ensured that the required mechanical properties are achievedthroughout the entire bar cross section. With the exception of toughness, the difference inproperties across the bar cross section shall not exceed 7 5%.

Tensile testing shall be conducted according to EN 10002 resp. ASTM E8M (round tension test specimen with Lo = 50 mm and do = 10 mm) or ASTM E8. Impact testing shall be performed with standard test pieces with V-notch according to EN10045. The following properties at room temperature must be demonstrated by the following tests;

yield strength:≥550 MPa

elongation:≥20%

-hardness :≤250HB

We have following inspection equipment of testing all our X18CrMnMoNbVN12 forging steel parts

Ultrasonic equipment

1. Automatic ultrasonic testing: two ultrasonic testing facilities for internal defects (NDT) with automatic drive and data acquisition system2. Manual ultrasonic testing: for intemal defects (NDT)

Magnetic particle:Surface defects testing with magnetic particle or

dye penetrant inspection (visible or fluorescentpenetrant testing (FPI) method)

Measuring equipment

Dimensional checking

Microscope

Scanning electron microscope (SEM) for investiga-tions of the microstructure

Mechanical testing

Checking the mechanical properties of the equipment

material on state of the art automatic testingequipment