Description

Jiangsu Liangyi is professional manufacturer of 1.4944,X5NiCrTi26-15 ,X5NiCrTi26.15 ,X5NiCrTi2615 open die forging parts and seamless rolled steel forged rings from china

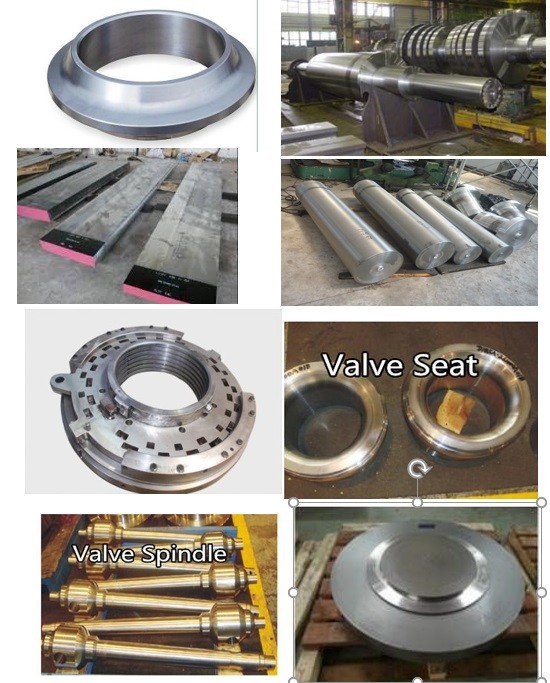

Following is the shape of 1.4944,X5NiCrTi26-15 ,X5NiCrTi26.15 ,X5NiCrTi2615 forging steel material that we could do is:1.4944 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,1.4944 Forged forging steel rings seamless rolled rings,1.4944 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,X5NiCrTi26-15 Forged Forging Steel Discs Disks Blocks plates,1.4944 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 1.4944,X5NiCrTi26-15 ,X5NiCrTi26.15 ,X5NiCrTi2615 material that is used in following industry

1.4944 Forged Forging Turbine and Compressor Labyrinth Shaft Seals

X5NiCrTi26-15 forged forging Railway locomotive Traction Motors Non-magnetic Forging Forged Retaining Rings factory

1.4944 forged forging Electromagnetic Stirring Rolls Rollers for continuous casting machine

1.4944 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

1.4944 Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

1.4944 Forged Forging venturi cone meter Body Bodies Blocks

X5NiCrTi26-15 Forged Forging Steel gate valves Body Bodies bespoke flat bars

1.4944 forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

1.4944 Forged Forging Steel double studded adapter flange

1.4944 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

1.4944 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

1.4944 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

1.4944 Forged Forging forge Steel transition Cone

X5NiCrTi26-15 Forged Forging Steel Pressure Vessel Reactor Nozzles

1.4944 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

1.4944 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs,turbine wheel discs

1.4944 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

1.4944 Forging Steel gas steam Turbine Guide Rings,Turbine shroud rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

1.4944 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

1.4944 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

1.4944 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

X5NiCrTi26-15 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

1.4944 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

1.4944 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

1.4944 is is an austenitic precipitation-hardenable stainless steel that is generally configured for long-term and high-temperature use with a service temperature reaching up to 700 °C. It is considered as an iron-based superalloy due to its high strength and resistance to corrosion at high temperatures.

1.4944 is widely used in aviation and power engineering for heavy-duty rotors, gas turbine blades, steam turbines, pressure equipment parts and reactors, jet engines and rockets, exhaust systems. Also used in cryogenics and cryotechnics.

The raw material OF1.4944 FORGING Parts can be manufactured according to one of these three methods:

Method A: Air melt and vacuum refined (AM/VR),

Method B: Vacuum induction melted and vacuum arc refined (VIM/VAR).

Method C: Air melt and vacuum arc refined (AM/VAR).

FOllowing is chemical compostion of 1.4944 forged parts

C(%) 0.03-0.08

Si(%) Max 1.00

Mn(%) 1.00-2.00

P(%) Max 0.025

S(%) Max 0.015

Cr(%) 13.5-16

Ni(%) 24.0-27.0

Mo(%) 1.00-1.50

V(%) 0.10-0.50

Al(%) Max 0.35

Ti(%)1.90-2.30

Following of 1.4944 forging parts heat treatment nechanical property Delivery condition :

Mechanical properties

Tensile strength Rm 900 - 1150 MPa

Yield point Re > 600 MPa

Elongation A > 15%

The mechanical testing shall be performed on the qualification on its QTC representing the heat and heat treatment lot in accordance with ASTM A370, ASTM E8 or ISO 6892-1.

Hardness testing shall be in accordance with:

— ISO 6506-1 or ASTM E10, or

— ISO 6508-1 or ASTM E18.

—ISO 6507-1 or ASTM E384 maybe used if ISO 6506-1 or ISO 6508-1 cannot be applied due to size, accessibility, or other limitations.

CVN impact testing shall be in accordance with ASTM E23 or any equivalent specification

The following information is mandatory on the certified record of all our 1.4944 forging parts:

Purchase Order number and MISSION VG Specification number complete with revision letter.

Statement of the melting process used.

Chemical analysis and heat number.

Statement of heat treatment including time/temperature cycle, cooling media, and hardness of the forging and coupon separately.

Statement of actual values of the mechanical properties which wereobtained from the test coupon, as stipulated in paragraph 5.0.

The number of forgings or hot rolled bars submitted from each heat.

Liquid Penetrant or Magnetic Particle reports.

Ultrasonic Testing or Radiography reports.

Documentation in accordance with NACE MR0175/ISO15156 and EN 10204, Type 3.1.

Welcome your inquiry of 1.4944,X5NiCrTi26-15 ,X5NiCrTi26.15 ,X5NiCrTi2615, ) forging forged steel parts

Following is the shape of 1.4944,X5NiCrTi26-15 ,X5NiCrTi26.15 ,X5NiCrTi2615 forging steel material that we could do is:1.4944 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,1.4944 Forged forging steel rings seamless rolled rings,1.4944 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,X5NiCrTi26-15 Forged Forging Steel Discs Disks Blocks plates,1.4944 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 1.4944,X5NiCrTi26-15 ,X5NiCrTi26.15 ,X5NiCrTi2615 material that is used in following industry

1.4944 Forged Forging Turbine and Compressor Labyrinth Shaft Seals

X5NiCrTi26-15 forged forging Railway locomotive Traction Motors Non-magnetic Forging Forged Retaining Rings factory

1.4944 forged forging Electromagnetic Stirring Rolls Rollers for continuous casting machine

1.4944 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

1.4944 Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

1.4944 Forged Forging venturi cone meter Body Bodies Blocks

X5NiCrTi26-15 Forged Forging Steel gate valves Body Bodies bespoke flat bars

1.4944 forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

1.4944 Forged Forging Steel double studded adapter flange

1.4944 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

1.4944 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

1.4944 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

1.4944 Forged Forging forge Steel transition Cone

X5NiCrTi26-15 Forged Forging Steel Pressure Vessel Reactor Nozzles

1.4944 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

1.4944 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs,turbine wheel discs

1.4944 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

1.4944 Forging Steel gas steam Turbine Guide Rings,Turbine shroud rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

1.4944 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

1.4944 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

1.4944 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

X5NiCrTi26-15 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

1.4944 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

1.4944 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

1.4944 is is an austenitic precipitation-hardenable stainless steel that is generally configured for long-term and high-temperature use with a service temperature reaching up to 700 °C. It is considered as an iron-based superalloy due to its high strength and resistance to corrosion at high temperatures.

1.4944 is widely used in aviation and power engineering for heavy-duty rotors, gas turbine blades, steam turbines, pressure equipment parts and reactors, jet engines and rockets, exhaust systems. Also used in cryogenics and cryotechnics.

The raw material OF1.4944 FORGING Parts can be manufactured according to one of these three methods:

Method A: Air melt and vacuum refined (AM/VR),

Method B: Vacuum induction melted and vacuum arc refined (VIM/VAR).

Method C: Air melt and vacuum arc refined (AM/VAR).

FOllowing is chemical compostion of 1.4944 forged parts

C(%) 0.03-0.08

Si(%) Max 1.00

Mn(%) 1.00-2.00

P(%) Max 0.025

S(%) Max 0.015

Cr(%) 13.5-16

Ni(%) 24.0-27.0

Mo(%) 1.00-1.50

V(%) 0.10-0.50

Al(%) Max 0.35

Ti(%)1.90-2.30

Following of 1.4944 forging parts heat treatment nechanical property Delivery condition :

Mechanical properties

Tensile strength Rm 900 - 1150 MPa

Yield point Re > 600 MPa

Elongation A > 15%

The mechanical testing shall be performed on the qualification on its QTC representing the heat and heat treatment lot in accordance with ASTM A370, ASTM E8 or ISO 6892-1.

Hardness testing shall be in accordance with:

— ISO 6506-1 or ASTM E10, or

— ISO 6508-1 or ASTM E18.

—ISO 6507-1 or ASTM E384 maybe used if ISO 6506-1 or ISO 6508-1 cannot be applied due to size, accessibility, or other limitations.

CVN impact testing shall be in accordance with ASTM E23 or any equivalent specification

The following information is mandatory on the certified record of all our 1.4944 forging parts:

Purchase Order number and MISSION VG Specification number complete with revision letter.

Statement of the melting process used.

Chemical analysis and heat number.

Statement of heat treatment including time/temperature cycle, cooling media, and hardness of the forging and coupon separately.

Statement of actual values of the mechanical properties which wereobtained from the test coupon, as stipulated in paragraph 5.0.

The number of forgings or hot rolled bars submitted from each heat.

Liquid Penetrant or Magnetic Particle reports.

Ultrasonic Testing or Radiography reports.

Documentation in accordance with NACE MR0175/ISO15156 and EN 10204, Type 3.1.

Welcome your inquiry of 1.4944,X5NiCrTi26-15 ,X5NiCrTi26.15 ,X5NiCrTi2615, ) forging forged steel parts