Description

Jiangsu Liangyi professional manufacturer of 2.4634,NiCo20Cr15MoAlTi,NiCo 20 Cr 15 MoAlTi open die forging parts and seamless rolled steel forged rings from china

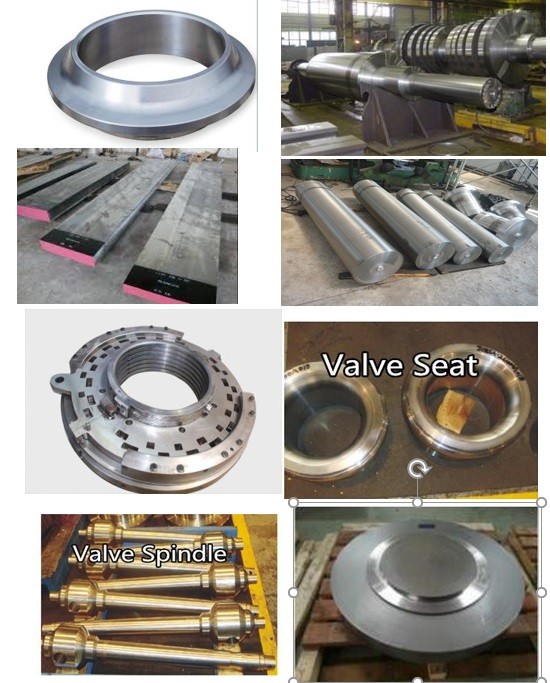

Following is the shape of 2.4634,NiCo20Cr15MoAlTi,NiCo 20 Cr 15 MoAlTi forging steel material that we could do is:NiCo20Cr15MoAlTi Forged Steel round bars square bars Flat bars Rectangles Bars Rods,2.4634 Forged forging steel rings seamless rolled rings,NiCo20Cr15MoAlTi Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,2.4634 Forged Forging Steel Discs Disks Blocks plates,NiCo 20 Cr 15 MoAlTi Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 2.4634,NiCo20Cr15MoAlTi,NiCo 20 Cr 15 MoAlTi material that is used in following industry

2.4634 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

NiCo20Cr15MoAlTi Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

NiCo 20 Cr 15 MoAlTi Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

2.4634 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

NiCo 20 Cr 15 MoAlTi Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

NiCo20Cr15MoAlTi Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

NiCo20Cr15MoAlTi Forged Forging Steel power plant steam turbine control reheat valve disc Disk

NiCo 20 Cr 15 MoAlTi Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

NiCo 20 Cr 15 MoAlTi Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

2.4634 is s a wrought nickel-cobalt-chromium-base alloy strengthened by additions of molybdenum, aluminum and titanium. It has been developed for service up to 950°C, and combines the high strength of the age-hardening nickel-base alloys with good creep resistance. Nimonic alloy 105 is produced by high frequency melting in air followed by casting in air, or, for more critical applications the alloy is produced by vacuum melting and electroslag refining. The alloy is used for turbine blades, discs, forgings, ring sections, bolts and fasteners.

The raw material OF 2.4634 FORGING Parta can be manufactured according to one of these three methods:

Method A: Air melt and vacuum refined (AM/VR),

Method B: Vacuum induction melted and vacuum arc refined (VIM/VAR).

Method C: Air melt and vacuum arc refined (AM/VAR).

Chemical composition of 2.4634,NiCo20Cr15MoAlTi,NiCo 20 Cr 15 MoAlTi forging turbine parts is as

Element Content (%)

Nickel, Ni 51

Cobalt, Co 18-22

Chromium, Cr 14-15.7

Molybdenum, Mo 4.50-5.50

Aluminum, Al 4.50-4.90

Iron, Fe 1

Manganese, Mn 1

Silicon, Si 1

Titanium, Ti 0.90-1.50

Copper, Cu 0.20

Zirconium, Zr 0.15

Carbon, C 0.12

Sulfur, S 0.010

Boron, B 0.0030-0.010

HEAT TREATMENT NiCo20Cr15MoAlTi forged turbine blade material is as followin

Solution annealing for 4 h at 1149°C (2100°F) followed by air cooling.

Heating for 16 h at 1056°C (1925°F) followed by air cooling.

Heating for 16 h at 849°C (1560°F).

Air cooling to reach precipitation-hardening.

mechanical property of for 2.4634,NiCo20Cr15MoAlTi,NiCo 20 Cr 15 MoAlTi forged round bars is as follow

Tensile Strength Minimum (psi) Min 167,000

Yield Strength Minimum 0.2% offset (psi) min 112,000

Elongation in 2" Minimum 25

The material of 2.4634 forged parts shall be free from blisters, cracks and slag inclusion. The surface ofmaterial shall be even and free from mill scale, forging folds, corrosion damage orother faults which may affect their usability.

Ultrasonic examination shall be carried out on 2.4634 each bar, 2.4634 forging or 2.4634 finished parts.Unacceptable defects are:

Cracks

Fault indications corresponding to a flat-bottomed hole FBH> ф3mm

Fault indications corresponding to a flat-bottomed hole FBH2 ф1.5mm with alength 2 30mm

Reports shall be submitted in the event of:

Fault indications corresponding to a flat-bottomed hole FBH 2 ф2mm

Fault indications corresponding to a flat-bottomed hole FBH 2 ф1 .5mm withmeasurable length.

SELECTION OF TEST SAMPELS of 2.4634 forged material

From each cast, six test samples of sufficient length shall be taken randomly throughout the cast but representative of six different extrusions of the samenominal dimensions.

PERPARATION OF TEST SAMPELS of 2.4634 forged products

Nominal Dimensions of Bar 10 mm to less than 20 mm

(a) The test samples shall be fully heat treated in accordance with the requirementsof this specification.

(b) Two* test pieces shall be machined coaxially from each test samples.

One test piece from each test sample shall be subjected to the stress rupture test at 815 degree, the remaining test piece to be subjected to the stress rupture atdegree.

. Nominal Dimensions of Bar 20 mm up to and including 50 mm

(a) The test samples shall be single-blow or multi-blow in one heat, side forged at atemperature of 1140+-10degree to a Cheese" having the. following nominalthickness.

Nominal Dimensions of Bar (mm):20<=40, Nominal Dimensions of "Cheese" (mm):13

Nominal Dimensions of Bar (mm):>40<=50, Nominal Dimensions of "Cheese" (mm):20

Nominal Dimensions of "Cheese" (mm)

(b) Tow* test bars shall be taken from each Cheese". The positions from which thetest pieces shall be taken are indication in Appendix2 of this specification.

* One test piece from each "Cheese" shall be subjected to the stress rupture at 815 DEGREE, the remaining test piece to be subjected to the stress rupture at 950 DEGREE

(c) The test bars" shall be finally heat treated in accordance with the requirement

Welcome your inquiry of 2.4634,NiCo20Cr15MoAlTi,NiCo 20 Cr 15 MoAlTi forging parts