Description

Jiangsu Liangyi is professional manufacturer of 1.8928,S690QL open die forging forged parts forged forging rings and forged forging steel parts factory from china

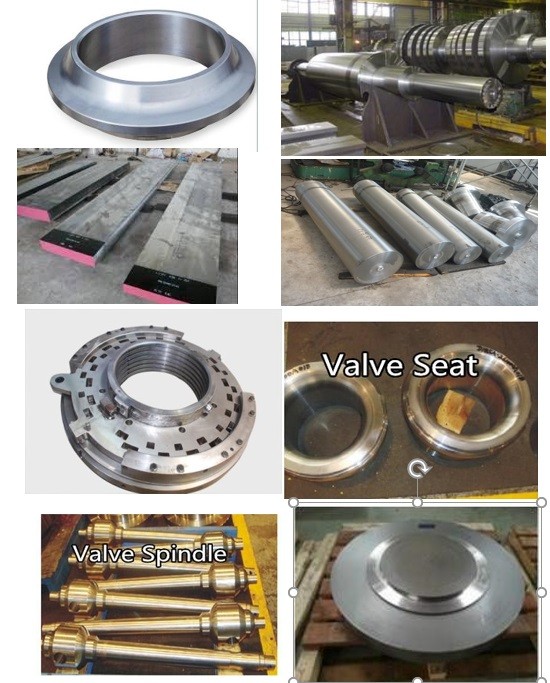

Following is the shape of 1.8928,S690QL forging steel material that we could do is:1.8928,S690QL Forged Steel round bars square bars Flat bars Rectangles Bars Rods,1.8928 Forged forging steel rings seamless rolled rings,1.8928 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,S690QL Forged Forging Steel Discs Disks Blocks plates,1.8928 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

The maximum diamter of 1.8928 forging steel parts in we could produce is 3 meter, the maximum weight of 1.8928 forging steel material that we could produce is 25 tons, the maximum length of S690QL forging steel products that we could do is 12 meter

Our 1.8928 forged steel raw material is normal melting by Basic Electric Furnace (EAF, AOD, VOD) or + Electroslag remelting. (ESR) AS PER CLIENTS NEEDS

1.8928 is a high-strength, low-alloy structural steel, is gaining prominence in modern defense applications. Recognized by its standard designation, 1.8928, this steel variant offers an exceptional balance of strength, toughness, and weldability, making it an ideal material for defense-related constructions where weight reduction without compromising structural integrity is crucial.

FOllowing is production standard of S690QL forging parts

EN 10025-6: 2004 Hot rolled products of structural steels. Technical delivery conditions for flat products of high yield strength structural steels in the quenched and tempered condition

EN 10137-2: 1996 Plates and wide flats made of high yield strength structural steels in the quenched and tempered or precipitation hardened conditions. Delivery conditions for quenched and tempered steels

The chemical compostion of 1.8928 forging parts that we could produce is as followings

C max 0.2

Si max 0.8

Mn max 1.7

Ni max 2

P max 0.02

S max 0.01

Cr max 1.5

Mo max 0.7

V max 0.12

N max 0.015

Nb max 0.06

Ti max 0.05

Cu max 0.5

Zr max 0.15

B max 0.005

CEV max 0.83

FOllowing is heat treatment mechanical property of 1.8928,S690QL forging steel parts

Nominal thickness (mm): 3 - 50

Rm - Tensile strength (MPa) 770-940

Nominal thickness (mm): 3 - 50

ReH - Minimum yield strength (MPa) 690

KV - Impact energy (J) longitud., 0°50 -20°

A - Min. elongation Lo = 5,65 √ So (%) 14

All our 1.8928,S690QL forged material will have following inspection:

Chemical analyses

Mechanical analyse

UT testing according several norms

MPI testing

Spectral analyse

Hardness measurement according several methods

Tensile and bending tests

Impact test according several methods

Microscope investigation

Huey test

Interkristal corrosion test

Red white test

X-Ray test

3D dimensional check

Magnetic test

Dye penetrant test

Positive Alloy Material Identification (PAMI)

Magnetic particle test

Welcome your inquiry of 1.8928,S690QL forged steel parts

Following is the shape of 1.8928,S690QL forging steel material that we could do is:1.8928,S690QL Forged Steel round bars square bars Flat bars Rectangles Bars Rods,1.8928 Forged forging steel rings seamless rolled rings,1.8928 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,S690QL Forged Forging Steel Discs Disks Blocks plates,1.8928 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

The maximum diamter of 1.8928 forging steel parts in we could produce is 3 meter, the maximum weight of 1.8928 forging steel material that we could produce is 25 tons, the maximum length of S690QL forging steel products that we could do is 12 meter

Our 1.8928 forged steel raw material is normal melting by Basic Electric Furnace (EAF, AOD, VOD) or + Electroslag remelting. (ESR) AS PER CLIENTS NEEDS

1.8928 is a high-strength, low-alloy structural steel, is gaining prominence in modern defense applications. Recognized by its standard designation, 1.8928, this steel variant offers an exceptional balance of strength, toughness, and weldability, making it an ideal material for defense-related constructions where weight reduction without compromising structural integrity is crucial.

FOllowing is production standard of S690QL forging parts

EN 10025-6: 2004 Hot rolled products of structural steels. Technical delivery conditions for flat products of high yield strength structural steels in the quenched and tempered condition

EN 10137-2: 1996 Plates and wide flats made of high yield strength structural steels in the quenched and tempered or precipitation hardened conditions. Delivery conditions for quenched and tempered steels

The chemical compostion of 1.8928 forging parts that we could produce is as followings

C max 0.2

Si max 0.8

Mn max 1.7

Ni max 2

P max 0.02

S max 0.01

Cr max 1.5

Mo max 0.7

V max 0.12

N max 0.015

Nb max 0.06

Ti max 0.05

Cu max 0.5

Zr max 0.15

B max 0.005

CEV max 0.83

FOllowing is heat treatment mechanical property of 1.8928,S690QL forging steel parts

Nominal thickness (mm): 3 - 50

Rm - Tensile strength (MPa) 770-940

Nominal thickness (mm): 3 - 50

ReH - Minimum yield strength (MPa) 690

KV - Impact energy (J) longitud., 0°50 -20°

A - Min. elongation Lo = 5,65 √ So (%) 14

All our 1.8928,S690QL forged material will have following inspection:

Chemical analyses

Mechanical analyse

UT testing according several norms

MPI testing

Spectral analyse

Hardness measurement according several methods

Tensile and bending tests

Impact test according several methods

Microscope investigation

Huey test

Interkristal corrosion test

Red white test

X-Ray test

3D dimensional check

Magnetic test

Dye penetrant test

Positive Alloy Material Identification (PAMI)

Magnetic particle test

Welcome your inquiry of 1.8928,S690QL forged steel parts