Description

Jiangsu Liangyi professional manufacturer of Nimonic C-263, Nimonic 263, ALloy 263,UNS N07263 open die forging parts and seamless rolled steel forged rings from china

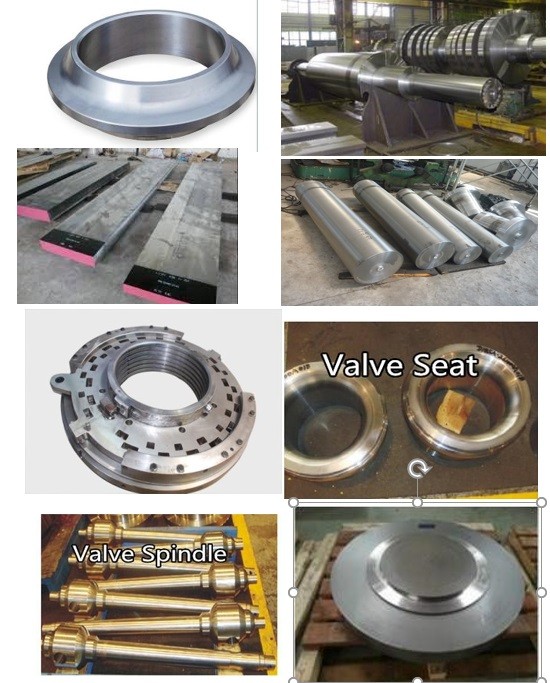

Following is the shape of Nimonic C-263, Nimonic 263, ALloy 263,UNS N07263,ALloy C263 forging steel material that we could do is:Nimonic 263 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Nimonic C-263 Forged forging steel rings seamless rolled rings,Nimonic 263 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,UNS N07263 Forged Forging Steel Discs Disks Blocks plates,ALloy 263 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of Nimonic C-263, Nimonic 263, ALloy 263,UNS N07263,ALloy C263 material that is used in following industry

Nimonic C-263 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

Nimonic 263 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

ALloy 263 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

UNS N07263 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

ALloy 263 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

Nimonic 263 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

Nimonic 263 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

ALloy 263 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

ALloy 263 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

NIMONIC Alloy 263 is an age-hardenable nickel-cobalt chromium-molybdenum alloy designed specifically to combine good, aged strength properties with excellent fabrication characteristics in the annealed condition. While its strength at elevated temperatures is not quite as high as Waspaloy® or Rene 41, Alloy C263 forged parts exhibits excellent intermediate temperature tensile ductility, and is not normally subject to strain age cracking problems common for other gamma prime strengthened alloys. This grade is typically used for applications up to about 1650°F (900°C). This grade combines properties which make it suitable for a variety of fabricated components in both aircraft turbine engine and land-based turbine applications.

The following methods are admitted for melting Alloy 263 forging parts :

- melting by electric air furnace with elaboration of alloy ( EAF & A OD or VO D ) or vacuum melting (VIM ) ;

- re melting under slag ( ES R ) or under vacuum ( VAR ) .

The NIMONIC 263 forged material shall undergo the following heat treatment:

Nimonic alloy 263 should be given a two-stage heat-treatment carried out in the air, or more specifically solution treatment and age hardening. Here are all the details on recommended heat treatments for different forms of the alloy:

NIMONIC 263 forged bars and a section for forging and /or machining – 1.5-2.5h at 2102°F (1150°C)/WQ for solution treatment and 8 h at 1472°F (800°C)/AC for aging treatment;

Chemical composition of Nimonic C-263, Nimonic 263, ALloy 263,UNS N07263,ALloy C263 forging turbine parts is as follows

Carbon ........................................................................0.04-0.08

Silicon .........................................................................0.40 max.

Manganese .................................................................0.60 max.

Sulfur ........................................................................0.007 max.

Silver.......................................................................0.0005 max.

Aluminum....................................................................0.60 max.

Boron ........................................................................0.005 max.

Bismuth...................................................................0.0001 max.

Cobalt..........................................................................19.0-21.0

Chromium....................................................................19.0-21.0

Copper........................................................................0.20 max.

Iron................................................................................0.7 max.

Molybdenum ...................................................................5.6-6.1

Lead........................................................................0.0020 max.

Titanium...........................................................................1.9-2.4

Aluminum and titanium ...................................................2.4-2.8

Nickel............................................................................Balance*

mechanical property of for Nimonic C-263, Nimonic 263, ALloy 263,UNS N07263,ALloy C263 forged round bars is as follow

Tensile strength (precipitation hardened at room temperature) 940 MPa 136,000 psi

Yield strength (, precipitation hardened, value at room temperature) 550 MPa 79,800 psi

Elongation at break (precipitation hardened) 39%

Removal of test samples of UNS N07263 forged round bars

Unless otherwise indicated on the drawing or in the specification for the part , removal is to be effected as follows :

- longitudinal if the section can be inscribed in a circle with diameter < 1 0 0 mm

- transverse if the section can be inscribed in a circle with diameter ≥ 1 0 0 mm

- tangential for nimonic 263 forged rings or disks

The tests for nimonic 263 forgeed material are to be performed according to AST M E18 , ASTM E21 , AST ME139 , ASTM E290 . The test bars shall have useful diameter of 6 . 2 5 mm or as large as possible , in relation to the thickness from which they are taken .

Micro graphic characteristics of nimonic C263 forging rings is as follows

Grain size according to ASTM E112 for thickness ≤ 5 mm , dimension 3 or finer

for thickness > 5 mm , dimension 2 or finer

Welcome your inquiry of Nimonic C-263, Nimonic 263, ALloy 263,UNS N07263,ALloy C263 forging parts