Description

Jiangsu Liangyi professiona is l manufacturer of Inconel 925,UNS N09925,,Alloy 925,Incoloy 925, Incoloy Alloy 925 open die forging parts and seamless rolled steel forged rings from china

Following is the shape of Inconel 925,Incoloy 925, Alloy 925,UNS N09925 forging steel material that we could do is:Inconel 925 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Incoloy 925 Forged forging steel rings seamless rolled rings,Alloy 925 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,UNS N09925 Forged Forging Steel Discs Disks Blocks plates,Inconel 925 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of Inconel 925,Incoloy 925, Alloy 925,UNS N09925 material that is used in following industry

Alloy 925 forged forging gas separator protector intake HPS splined shaft

Incoloy 925 forging Forged Drilling Pipes Tubes Drill Rods drill Drilling collar

Incoloy 925 Forged/Forging Blow Out Blowout Preventer RAM Annular dual Bop Body Bodies Block

Alloy 925 Forged Forging drilling tools,risers,connectors,flexible joint ,seals,flanges gasket

Inconel 925 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

Incoloy 925 Forged Forging Steel Butterfly Valve Main Shafts Spindles

Alloy 925 Forged Forging Swept branches outlets steel fittings swept saddles

Inconel 925 Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

Incoloy 925 Forged Forging Steels Christmas Trees wellhead Spool Body Bodies cylinder

Alloy 925 Forged Forging venturi cone meter Body Bodies Blocks

UNS N09925 Forged Forging Steel gate valves Body Bodies bespoke flat bars

Inconel 925 forged steel Flowseal cryogenic High Performance BV Butterfly Valves HPBV shaft

Inconel 925 forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

Incoloy 925 Forged Forging Steel double studded adapter flange

Incoloy 925 Forged Forging Steel integral Mud Flange Flanged outlet Studded crosses

UNS N09925 Forged Forging Steel Casing Heads,Tubing Heads,Casing Hangers,Tubing Hangers,Tubing Spools,Casing Spools,Spacer Spools

Incoloy 925 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

Alloy 925 Forged Forging forge Steel transition Cones

Incoloy 925 forged foring marine ship shafts

Incoloy 925 is an age-hardenable nickel-iron-chromium alloy that has excellent corrosion resistance as well as good high strength properties. Alloying additions of molybdenum, copper, titanium, and aluminum provide resistance to pitting/crevice corrosion, chloride induced stress corrosion cracking, oxidizing environments, and reducing chemicals. The additions also allow age-hardening of the material via heat treatment for increased strength.

Melting Practices of our incoloy alloy 925 forging parts is as followings:

Material shall be melted by one o the following sequence of processes.

1. Step 1- Basic EF

Step 2- Either Argon Oxygen Decarburization (AOD) or Vacuum Oxygen Decarburization (VOD) or Vacuum Degrassing.

Step 3- Either Electroslag Remelting (ESR) or Electroflux Remelting (EFR) or Vacuum Arc Remelting (VAR).

Optional Step 4- Vacuum Arc Remelting (VAR)

OR

2. Step 1- Vacuum Induction Melting (VIM)

Step 2- Either Electroslag Remelting (ESR) or Electroflux Remelting (EFR) or Vacuum Arc Remelting (VAR).

Optional Step 3- Vacuum Are Remelting (VAR).

The minimum total hot forging reduction ratio of all our incoloy 925 round bars shall be 4:1.

FOllowing is chemical compostion of Incoloy 925 forged steel rings

Nickel...........................................................................42.0-46.0

Chromium ....................................................................19.5-22.5

Iron...................................................................................22 min

Molybdenum ....................................................................2.5-3.5

Copper.............................................................................1.5-3.0

Titanium ...........................................................................1.9-2.4

Aluminum.........................................................................0.1-0.5

Manganese ...................................................................1.0 max.

Silicon ...........................................................................0.5 max.

Niobium.........................................................................0.5 max.

Carbon ........................................................................0.03 max.

Sulfur ..........................................................................0.03 max

Mechanical properties of incoloy 925 forged hollow bars:

The mechanical testing shall be performed on the qualification on its QTC representing the heat and heat treatment lot in accordance with ASTM A370, ASTM E8 or ISO 6892-1.

Hardness testing shall be in accordance with:

— ISO 6506-1 or ASTM E10, or

— ISO 6508-1 or ASTM E18.

—ISO 6507-1 or ASTM E384 maybe used if ISO 6506-1 or ISO 6508-1 cannot be applied due to size, accessibility, or other limitations.

CVN impact testing shall be in accordance with ASTM E23 or any equivalent specification

|

Mechanical Properties |

Range |

|

Tensile Strength |

140,000 psi (Min) |

|

Yield Strength, psi 0.2% offset |

110,000 psi (Min) |

|

140,000 psi (Max) |

|

|

Elongation in 2" gage length |

18% (Min) |

|

Reduction in Area |

25% (Min) |

|

Minimum average CVN impact at -60° C |

47 joules |

|

Minimum single CVN impact at -60° C |

43 joules |

|

Hardness (HRC) |

38 (Max) |

Tensile tests shall be performed at a temperature between 4.4° C and 48.9° C in accordance with the procedures specified in ASTM A370. A minimum of one tensile testshall be performed Retesting: If the results of tensile test do not satisfy the applicable requirements, two additional tests on two additional specimens (removed from the same QTC with no additional heat treatment) maybe performed in an effort to qualify the material. The results of each of these tests shall satisfy the applicable requirements.

Material Qualification Test Coupons (QTC):

. QTC shall be used to establish the mechanical properties of each forging or bar product.

. Minimum one QTC will be required for each heat / per heat-treat lot. A QTC shall be obtained from either of the following:

A prolongation shall betaken from the ¼ T envelope location of the thickest section. 2. A sacrificial forging that is cut into specified segments for test coupons.

CVN impact testing shall be in accordance with ASTM 370 or ASTM E23 or any equivalent specification using the charphy V-notch technique. To qualify material for a temperature rating, impact tests shall be performed at -60°C or below temperature.

The test frequency shall be one set of tests per heat per heat treatment lot. The QTC shall be either a prolongation or sacrificial production part.

Three impact specimens (10mmx 10mm) shall be tested to qualify the material. Specimen orientation shall be longitudinal to the primary direction of grain flow. In no case shall an individual impact value fall below two-thirds of that required as a minimum average. No more than one of the three test results shall be below the required minimum average.

The subsize specimen will be permitted only if geometry does not permit a full size specimen to be utilized. The adjustment factors for sub-size specimen as specified in below table.

|

Specimen Dimension |

Adjustment Factor |

|

10 mmx 10 mm (full-size) |

1 (none) |

|

10 mmx 7.5 mm |

0.833 |

|

10 mmx 5.0 mm |

0.667 |

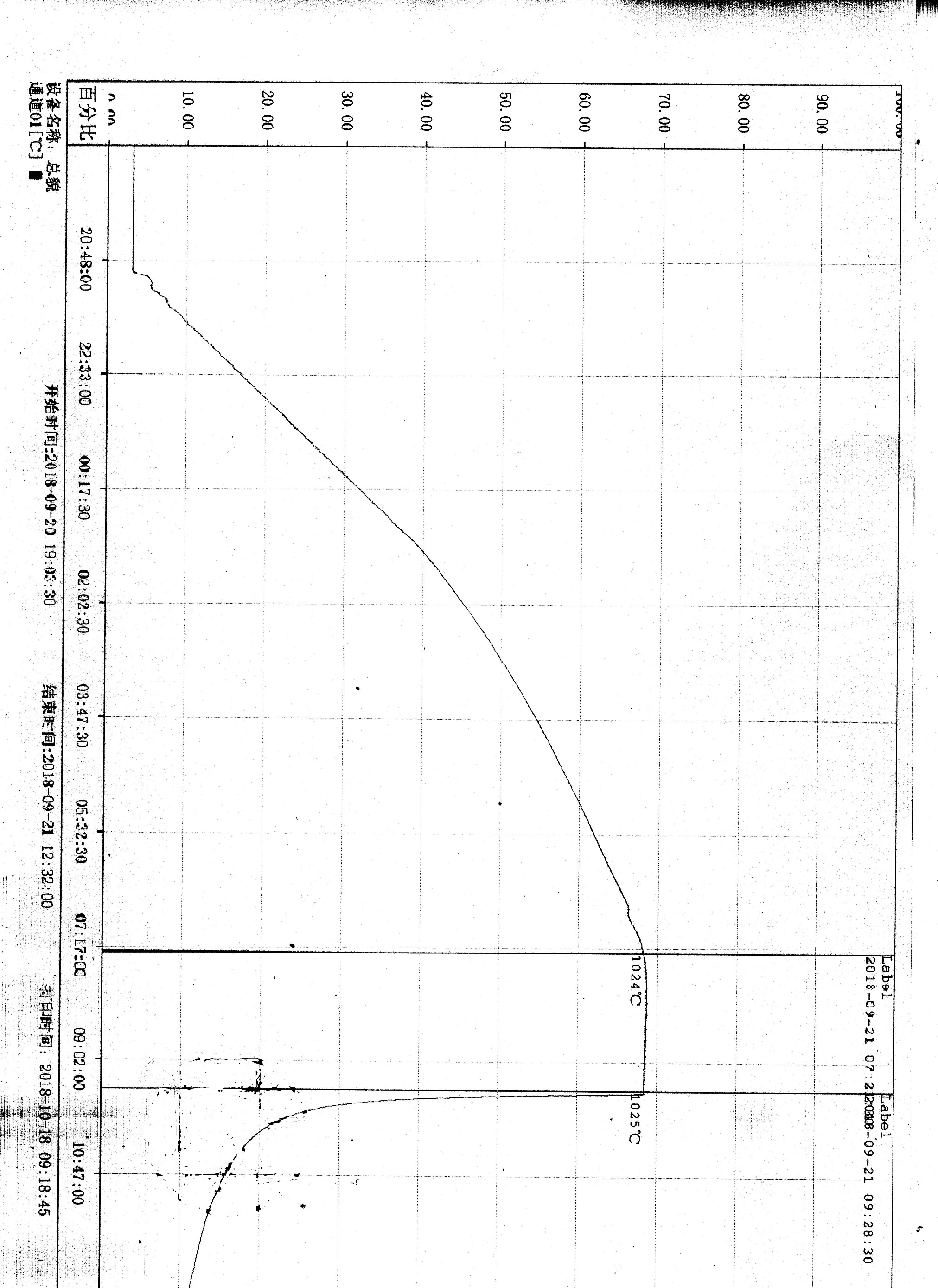

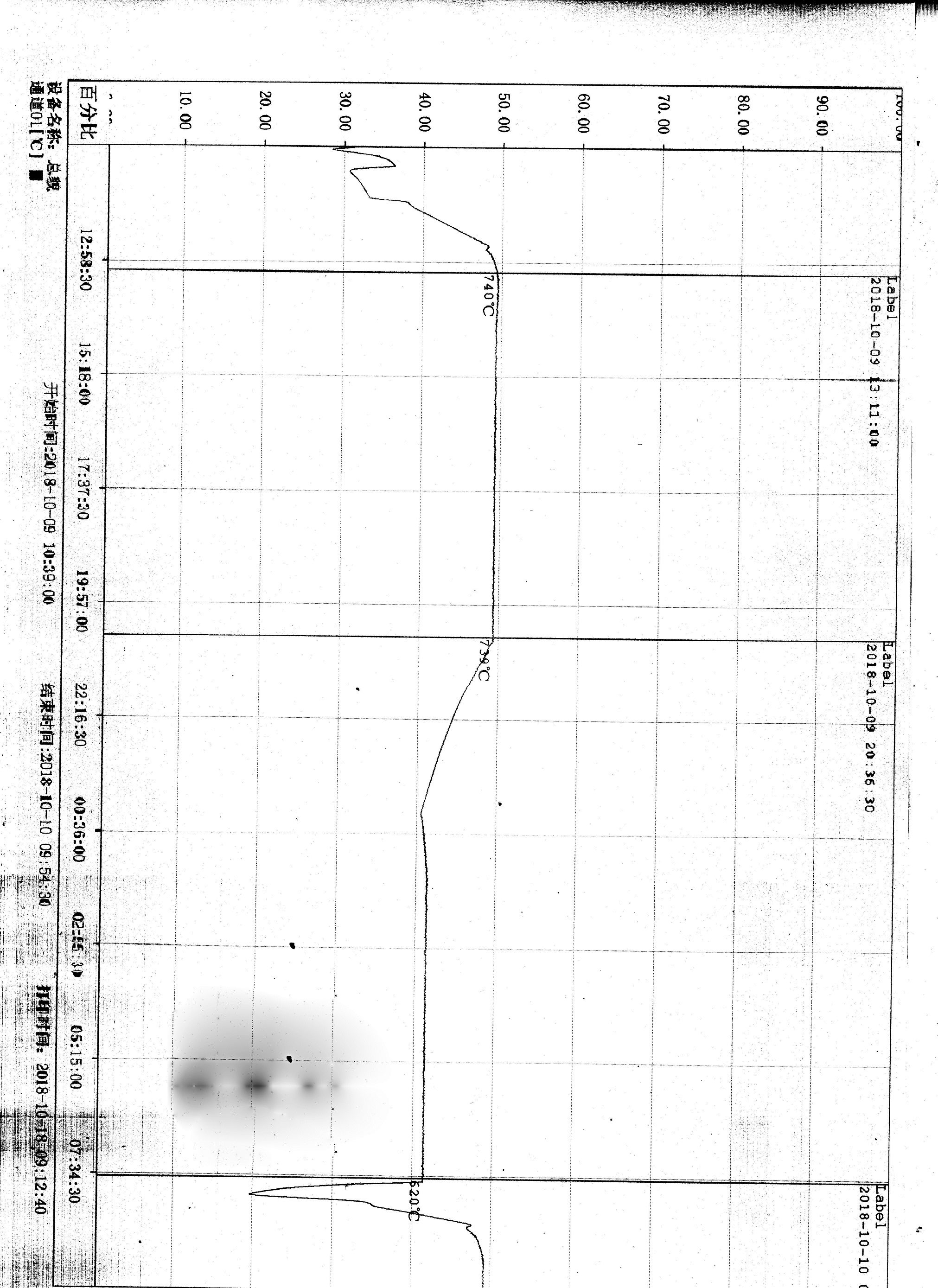

HEAT TREATMENT PRACTICES if inconel 925 forged parts is as follow:

Solution Annealing and Age Hardening:

The Production material and QTC(s) shall be solution annealed and age hardened in accordance with the following procedure:

. Solution Annealing:-

|

|

Medium |

Temperature ºF (º C) |

Hold period |

|

||

|

|

Annealing |

-- |

1825º F – 1925º F (996º C - 1052º C) |

Minimum for 30 minutes to maximum 4 hours |

|

|

|

|

Quenching |

Water |

100°F (38°C)Max Before quench |

-- |

||

|

120°F (49°C)Max During quench |

||||||

|

|

Medium |

Temperature ºF (º C) |

Hold period |

|

|

|

Age Hardening |

-- |

1325º F – 1400°F (718º C-760°C) |

4 hours to 9 hours. |

|

|

-- |

1125°F-1220°F (607°C-660°C) |

-- |

|

|

|

||||

|

|

Air |

Ambient Temperature |

-- |

|

Heat treatment chart of incoloy 925 forged bars

The acceptance criteria and inspection procedures of visual inspection, UT shall be as per API 6A, ASTM A388/388M and other relevant standards.

Ultrasonic Testing (UT) of inconel 925 forged hollow bars :

. Ultrasonic Inspection is required for all forgings after heat treatment for mechanical Properties exclusive of stress relief treatments or re-tempering to reduce hardness.

. UT examination methods shall be in accordance with ASTM A388/388M, ASTM E127 (ASTM E428) or ASTM E2375.

Calibration: The distance amplitude curve (DAC) shall be based on a maximum 1.6 mm (1/16

in.) flat-bottom hole (straight-beam technique) for metal thicknesses through 38.1 mm (1.1/2 in.), on a maximum 3.2 mm (1/8 in.) flat-bottom hole for metal thicknesses from 38.1 mm (1.1/2 in.)

through 152.4 mm (6 in.), and on a maximum 6.4 mm (1/4 in.) flat-bottom hole for metal thicknesses exceeding 152.4 mm (6 in.).

UT acceptance criteria

1. No single indications exceeding reference distance amplitude curve.

2. No multiple indications exceeding 50% of reference distance amplitude curve. Multiple indications are defined as two or more indications (each exceeding 50 % of the reference distance amplitude curve) within 12.7 mm (1/2”) of each other in any direction.

For API 6A PSL 4, additionally, volumetric NDE requirements shall include the following: Same acceptance criteria as mentioned above, with the addition that no continuous cluster of indications on the same plane, regardless of amplitude, shall be found over an area twice the diameter of the search unit.

Welcome your inquiry of Inconel 925,Incoloy 925, Alloy 925,UNS N09925) forging forged steel parts