Description

Jiangsu Liangyi professional manufacturer of 1.8070,21CrMoV5-11,21crmov511,21crmov5.11,21 CrMoV 5-11 open die forging parts and seamless rolled steel forged rings,forged pipes tubes,21CrMoV5-11 forging steel steel mill Continuous caster casting roll roller for a continuous casting machine,1.8070 forged forging steel gas steam turbine blade bolts rotor shafts from china

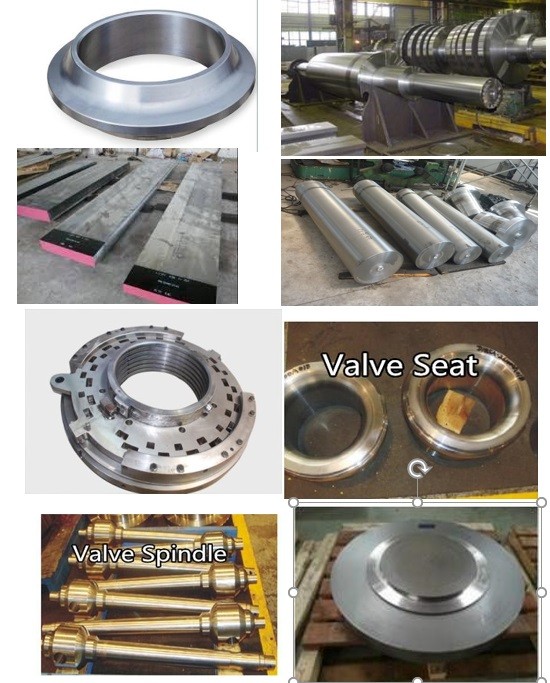

Following is the shape of 1.8070,21CrMoV5-11,21crmov511,21crmov5.11,21 CrMoV 5-11 forging steel material that we could do is:1.8070 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,21crmov511 Forged forging steel rings seamless rolled rings,21crmov5-11 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,21crmov5.11 Forged Forging Steel Discs Disks Blocks plates,21crmov511 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 1.8070,21CrMoV5-11 that is used in following industry

1.8070,21CrMoV5-11 forged forging steel mill Continuous caster casting roll roller for a continuous casting machine,Casting Steel Dummy Bars Heads

21CrMoV5-11 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

21CrMoV511 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

21CrMoV511 Forged Forging Gas steam turbine rotor shafts

21CrMoV511 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

1.8070 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

1.8070 is as pearlitic heat-resistant steel with high content Cr and Mo as per EN 10269 Standard. 21CrMoV5-11 forged steel parts can work at around 500 degrees for a long time and are mainly used in petrochemical, coal conversion, nuclear power, steam turbine cylinders, thermal power and other occasions with harsh conditions and corrosive media. Main applications: rolls, boilers, reactors, heaters, steam generation device, etc.

FOllowing is production and inspection standard of 1.8070,21CrMoV5-11 steel round bars

EN 10083-1:Quenched and tempered steels - Technical delivery conditions for special steels.

EN 10002-1:Metallic materials - Tensile testing - Part 1: method of test at ambient temperature.

EN 10002-5:Metallic materials - Tensile testing - Part 5: method of testing at elevated temperature.

EN 10045-1:Charpy impact test on metallic materials - Test method.

IS06506-1:Metallic materials - Brinell hardness test - Part 1: Test method,

FOllowing is melting methods of 1.8070,21CrMoV5-11 forged steel parts:EAF + VD + LF / BEF + ESR

All our 1.8070,21CrMoV5-11 forging steel rings can be release in 10204-3.2 certificate by following third party DNV-GL BUREAU VERITAS,LLOYD’S REGISTER,ABS, RINA,TÜV

FOllowing is chemical compostion of 1.8070 forging Pipes

Carbon:0.17 -0.25

Silicon :0.30- 0.60

Manganese :0.30- 0.60

Chromium :1.20 -1.50

Nickel :0.60 max

Molybdenum :1.00- 1.20

Phosphorus: 0.035 max

Sulphur: 0.035 max

Vanadium :0.25 - 0.35

FOllowing is mechanical property for 21CrMoV5-11 forging steel pipes

Mechanical properties in the quenched and tempered condition - at +20C

Yield strength :Min 540 MPA Test according to standard of EN 10002-1

Tensile stress:690 - 830 MPA Test according to standard of EN 10002-1

Elongation Min 18% Test according to standard of EN 10002-1

Cross section reduction:Min 25% Test according to standard of EN 10002-1

Hardness:230-280 HB Test according to standard of IS0 6506-1

Impact strength (KV method) Min 54J Test according to standard of EN 10045-1

Mechanical properties of 21CrMoV5-11 forging steel parts in the quenched and tempered condition - at 400*C

Yield strength :Min 400 MPA Test according to standard of EN 10002-5

All our 21CrMoV5-11 forged steel mill rolls will have following inspection:

Chemical analyses

Mechanical analyse

UT testing according several norms

MPI testing

Spectral analyse

Hardness measurement according several methods

Tensile and bending tests

Impact test according several methods

Microscope investigation

Huey test

Interkristal corrosion test

Red white test

X-Ray test

3D dimensional check

Magnetic test

Dye penetrant test

Positive Alloy Material Identification (PAMI)

Magnetic particle test