Description

Jiangsu Liangyi is professional manufacturer of 2.4854,NiFe33Cr25Co open die forging parts and seamless rolled steel forged rings from china

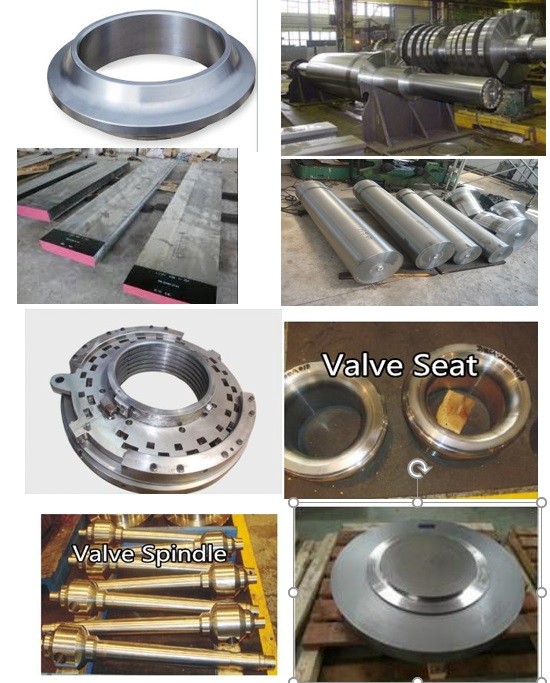

Following is the shape of 2.4854,NiFe33Cr25Co forging steel material that we could do is:2.4854 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,2.4854 Forged forging steel rings seamless rolled rings,NiFe33Cr25Co Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,NiFe33Cr25Co Forged Forging Steel Discs Disks Blocks plates,HAYNES HR120 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 2.4854,NiFe33Cr25Co material that is used in following industry

2.4854 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

NiFe33Cr25Co forged forging bearings and bearing races rings

2.4854 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

Bar Frame Heat Treating Baskets • Radiant Tubes

2.4854 Wire Mesh Furnace Belts and Basket Liners ,Cast Link Belt Pins,Muffles, Retorts,Recuperators

,Heat Treating Fixtures

2.4854 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings,valve trim, valve core, valve discs

2.4854 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

Forged HR-120 thermocouple protection tubes for waste incineration and chemical process facilities

2.4854 forged material for nuclear power such as :Flow limiter Venturi forgings (steam generator),Forged tubes for pressurizer surge line,reactor nozzles and primary pump fly wheels, divider plates for steam generator,Latch housings, rod travel housings and funnel extension,end ring and rotor stack plate forgings,bearing housings and stator end cap and closure ring forgings,Containment plates, rings and closure heads,Waste Flasks and Mounting Skirt,RPV Upper Shell and HSG Shell,Shell Strakes and Transition Cones,Pressure Components,Lifting Pin Tools and Trunnions,Pressuriser Upper Head and Upper Shell,Steam Drumhead and Lifting Pintle

2.4854 is solid solution reinforced heat resistant alloy that provides excellent high temperature strength and excellent strength against combined carburizing and sulfidizing environments. Its oxidation resistance is comparable to other commonly used Fe-Ni-Cr materials such as Alloy 330 and Alloy 800H, but its strength is significantly higher at temperatures up to 1095 ºC (2000 ºF) even compared to Ni-Cr alloys.

Forgings 2.4854 maeterial shall be manufactured from steel produced by vacuum induction melting 1 electro-slag re-melting {VIM/ESR) or by vacuum induction melting 1 vacuum are re-melting (VIM/VAR) process.

The 2.4854 forged material shall undergo the following heat treatment:

solution annealed condition, unless otherwise specified. Depending on the product form, the alloy is solution annealed at a temperature

ranging from 2150 to 2250 °F (1175 to 1230 °C) and rapidly cooled

The forgings 2.4854 forged parts shall be free from defects such as cracks, flakes, seams, segregation, non-metallic inclusionsand other defects which may affect the utility of the forgings.

Chemical composition of 2.4854,NiFe33Cr25Co forging turbine parts is as

Elements Content (%)

Nickel, Ni 30 - 45

Chromium, Cr 12 - 32

Cobalt, Co 5

Molybdenum, Mo 5

Columbium + Tantalum (Cb + Ta) 4

Silicon, Si 3

Manganese, Mn 2

Carbon, C 0.20

mechanical property of for 2.4854,NiFe33Cr25Co forged round bars is as follow

Ultimate Tensile Strength: 106.5 KSI (735 MPa)

Yield Strength: 45.6 KSI (375 MPa)

Elongation: 50%

ALl our finished producrtion of 2.4854,NiFe33Cr25Co forged round bars should have inspection certificate as per 3.1B of EN 10204 shall be provided to clients in triplicate;this certificate must contain the following dala:

(a)Material code no and P.O.number

(b)Material designation

(c)Heat no.,heat analysis and melting methods

(d)Table with the single results for determination pf the purity grade at microsections and value of purity grade K1

(e)Mechanical test results including hardness range

(f)Complete information on all heat treatments performed

(g)Results of NDT tests performed

(h)Confimation of material identification check

(i)Confirmation of dimensional and visual check

Following is testing standard of 2.4854,NiFe33Cr25Co forged rings

EN ISO 9000FF,EN 10002-1,ASTM E8M,ASTM E8,EN10045,EN10021,EN ISO 6506-1,ASTM E112,DIN 50602,DIN50601,ASTM E45,SEP 1923,EN 10204,ASTM A370,MUN 106.2/1.

Welcome your inquiry of 2.4854,NiFe33Cr25Co forging parts

Following is the shape of 2.4854,NiFe33Cr25Co forging steel material that we could do is:2.4854 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,2.4854 Forged forging steel rings seamless rolled rings,NiFe33Cr25Co Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,NiFe33Cr25Co Forged Forging Steel Discs Disks Blocks plates,HAYNES HR120 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 2.4854,NiFe33Cr25Co material that is used in following industry

2.4854 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

NiFe33Cr25Co forged forging bearings and bearing races rings

2.4854 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

Bar Frame Heat Treating Baskets • Radiant Tubes

2.4854 Wire Mesh Furnace Belts and Basket Liners ,Cast Link Belt Pins,Muffles, Retorts,Recuperators

,Heat Treating Fixtures

2.4854 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings,valve trim, valve core, valve discs

2.4854 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

Forged HR-120 thermocouple protection tubes for waste incineration and chemical process facilities

2.4854 forged material for nuclear power such as :Flow limiter Venturi forgings (steam generator),Forged tubes for pressurizer surge line,reactor nozzles and primary pump fly wheels, divider plates for steam generator,Latch housings, rod travel housings and funnel extension,end ring and rotor stack plate forgings,bearing housings and stator end cap and closure ring forgings,Containment plates, rings and closure heads,Waste Flasks and Mounting Skirt,RPV Upper Shell and HSG Shell,Shell Strakes and Transition Cones,Pressure Components,Lifting Pin Tools and Trunnions,Pressuriser Upper Head and Upper Shell,Steam Drumhead and Lifting Pintle

2.4854 is solid solution reinforced heat resistant alloy that provides excellent high temperature strength and excellent strength against combined carburizing and sulfidizing environments. Its oxidation resistance is comparable to other commonly used Fe-Ni-Cr materials such as Alloy 330 and Alloy 800H, but its strength is significantly higher at temperatures up to 1095 ºC (2000 ºF) even compared to Ni-Cr alloys.

Forgings 2.4854 maeterial shall be manufactured from steel produced by vacuum induction melting 1 electro-slag re-melting {VIM/ESR) or by vacuum induction melting 1 vacuum are re-melting (VIM/VAR) process.

The 2.4854 forged material shall undergo the following heat treatment:

solution annealed condition, unless otherwise specified. Depending on the product form, the alloy is solution annealed at a temperature

ranging from 2150 to 2250 °F (1175 to 1230 °C) and rapidly cooled

The forgings 2.4854 forged parts shall be free from defects such as cracks, flakes, seams, segregation, non-metallic inclusionsand other defects which may affect the utility of the forgings.

Chemical composition of 2.4854,NiFe33Cr25Co forging turbine parts is as

Elements Content (%)

Nickel, Ni 30 - 45

Chromium, Cr 12 - 32

Cobalt, Co 5

Molybdenum, Mo 5

Columbium + Tantalum (Cb + Ta) 4

Silicon, Si 3

Manganese, Mn 2

Carbon, C 0.20

mechanical property of for 2.4854,NiFe33Cr25Co forged round bars is as follow

Ultimate Tensile Strength: 106.5 KSI (735 MPa)

Yield Strength: 45.6 KSI (375 MPa)

Elongation: 50%

ALl our finished producrtion of 2.4854,NiFe33Cr25Co forged round bars should have inspection certificate as per 3.1B of EN 10204 shall be provided to clients in triplicate;this certificate must contain the following dala:

(a)Material code no and P.O.number

(b)Material designation

(c)Heat no.,heat analysis and melting methods

(d)Table with the single results for determination pf the purity grade at microsections and value of purity grade K1

(e)Mechanical test results including hardness range

(f)Complete information on all heat treatments performed

(g)Results of NDT tests performed

(h)Confimation of material identification check

(i)Confirmation of dimensional and visual check

Following is testing standard of 2.4854,NiFe33Cr25Co forged rings

EN ISO 9000FF,EN 10002-1,ASTM E8M,ASTM E8,EN10045,EN10021,EN ISO 6506-1,ASTM E112,DIN 50602,DIN50601,ASTM E45,SEP 1923,EN 10204,ASTM A370,MUN 106.2/1.

Welcome your inquiry of 2.4854,NiFe33Cr25Co forging parts