Description

Jiangsu Liangyi professional manufacturer of Nimonic ALloy 75, Nimonic 75, ALloy 75,UNS N06075 open die forging parts and seamless rolled steel forged rings from china

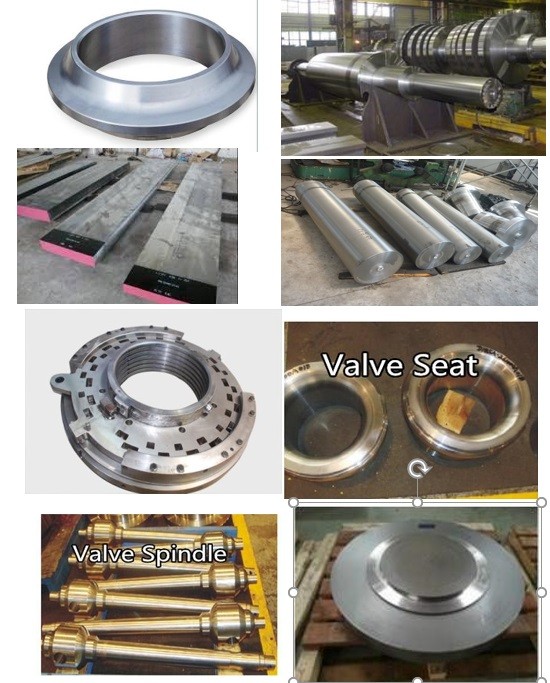

Following is the shape of Nimonic ALloy 75, Nimonic 75, ALloy 75,UNS N06075,nimonic75 forging steel material that we could do is:Nimonic 75 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Nimonic ALloy 75 Forged forging steel rings seamless rolled rings,Nimonic 75 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,UNS N06075 Forged Forging Steel Discs Disks Blocks plates,ALloy 75 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of Nimonic ALloy 75, Nimonic 75, ALloy 75,UNS N06075,nimonic75 material that is used in following industry

Nimonic ALloy 75 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

Nimonic 75 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

ALloy 75 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

UNS N06075 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

ALloy 75 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

Nimonic 75 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

Nimonic 75 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

ALloy 75 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

ALloy 75 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

Nimonic 75 forged material for nuclear power such as :Flow limiter Venturi forgings (steam generator),Forged tubes for pressurizer surge line,reactor nozzles and primary pump fly wheels, divider plates for steam generator,Latch housings, rod travel housings and funnel extension,end ring and rotor stack plate forgings,bearing housings and stator end cap and closure ring forgings,Containment plates, rings and closure heads,Waste Flasks and Mounting Skirt,RPV Upper Shell and HSG Shell,Shell Strakes and Transition Cones,Pressure Components,Lifting Pin Tools and Trunnions,Pressuriser Upper Head and Upper Shell,Steam Drumhead and Lifting Pintles

NIMONIC Alloy 75 a 80/20 nickel-chromium alloy with controlled additions of titanium and carbon. Nimonic 75 has good mechanical properties and oxidation resistance at high temperatures. Alloy 75 is most commonly used for sheet metal fabrications which require oxidation and scaling resistance together with medium strength at high operating temperatures. Alloy 75 (Nimonic 75) is also used in gas turbine engines, for components of industrial furnaces, for heat treating equipment and fixtures, and in nuclear engineering.

The NIMONIC 75 forged material shall undergo the following heat treatment:

30-60 minutes at 1050°C (1920°F) followed by air cooling

The forgings nimonic 75 forged parts shall be free from defects such as cracks, flakes, seams, segregation, non-metallic inclusionsand other defects which may affect the utility of the forgings.

Chemical composition of Nimonic ALloy 75, Nimonic 75, ALloy 75,UNS N06075,nimonic75 forging turbine parts is as

The chemical composition of NIMONIC 75 is as follows:

Carbon ........................................................................0.08-0.15

Chromium....................................................................18.0-21.0

Copper..........................................................................0.5 max.

Iron................................................................................5.0 max.

Manganese ...................................................................1.0 max.

Silicon ...........................................................................1.0 max.

Titanium...........................................................................0.2-0.6

Nickel............................................................................Balance

mechanical property of for Nimonic ALloy 75, Nimonic 75, ALloy 75,UNS N06075,nimonic75 forged round bars is as follow

Properties Metric Imperial

Tensile strength(annealed) 750 MPa 109 ksi

Yield strength(annealed) 275 MPa 40 ksi

Elongation at Break 42% 42%

Modulus of Elasticity 206 GPa 29878 ksi

.

The purity grade of the Nimonic ALloy 75, Nimonic 75, ALloy 75,UNS N06075,nimonic75 forged steel material is to be determined per DIN 50602-K1.The following value is to be kept in this case(on 1000 mm²)-Sum characteristics value K1:≤2.0

For determination 4 tests per heat are to be employed at least Depending on the appearance of the analysed microsections also higher K1-Values may possibly be Tolerated.Content of Delta-Ferrite Delta ferrite content:<5% (Determined in a manner consistent with the evaluation technique described in ASTM E 45/Method A,"Worst Field Method"at V=100,specimen orientation:longitudinal.Thedistribution and size of delta ferrite must be such that it does not result in indication in magnetic particle testing of the ready-machined surface.)

The following NDT inspections shall be performed after all heat treatments are performed

Visual inspection of all Nimonic ALloy 75, Nimonic 75, ALloy 75,UNS N06075,nimonic75 forging round bars

UT of all imonic ALloy 75 flat bars as per SEP 1923,inspection number D3 or D2 with dual (twin crystal search unit.100% of the volume shall be examined with the stipulated ecording level

Criteria stipulated in SEP 1923 quality class 2 b shall be applied with following modification:EE(single echo)and VE(numerous single echoes)without extension ≥2mm KSR are not permitted Defects above the recording limit shall be marked and it shall be ensured that these Nimonic 75 forging flat bars are not included in the lot delivered.

Welcome your inquiry of Nimonic ALloy 75, Nimonic 75, ALloy 75,UNS N06075,nimonic75 forging parts

Following is the shape of Nimonic ALloy 75, Nimonic 75, ALloy 75,UNS N06075,nimonic75 forging steel material that we could do is:Nimonic 75 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Nimonic ALloy 75 Forged forging steel rings seamless rolled rings,Nimonic 75 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,UNS N06075 Forged Forging Steel Discs Disks Blocks plates,ALloy 75 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of Nimonic ALloy 75, Nimonic 75, ALloy 75,UNS N06075,nimonic75 material that is used in following industry

Nimonic ALloy 75 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

Nimonic 75 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

ALloy 75 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

UNS N06075 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

ALloy 75 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

Nimonic 75 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

Nimonic 75 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

ALloy 75 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

ALloy 75 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

Nimonic 75 forged material for nuclear power such as :Flow limiter Venturi forgings (steam generator),Forged tubes for pressurizer surge line,reactor nozzles and primary pump fly wheels, divider plates for steam generator,Latch housings, rod travel housings and funnel extension,end ring and rotor stack plate forgings,bearing housings and stator end cap and closure ring forgings,Containment plates, rings and closure heads,Waste Flasks and Mounting Skirt,RPV Upper Shell and HSG Shell,Shell Strakes and Transition Cones,Pressure Components,Lifting Pin Tools and Trunnions,Pressuriser Upper Head and Upper Shell,Steam Drumhead and Lifting Pintles

NIMONIC Alloy 75 a 80/20 nickel-chromium alloy with controlled additions of titanium and carbon. Nimonic 75 has good mechanical properties and oxidation resistance at high temperatures. Alloy 75 is most commonly used for sheet metal fabrications which require oxidation and scaling resistance together with medium strength at high operating temperatures. Alloy 75 (Nimonic 75) is also used in gas turbine engines, for components of industrial furnaces, for heat treating equipment and fixtures, and in nuclear engineering.

The NIMONIC 75 forged material shall undergo the following heat treatment:

30-60 minutes at 1050°C (1920°F) followed by air cooling

The forgings nimonic 75 forged parts shall be free from defects such as cracks, flakes, seams, segregation, non-metallic inclusionsand other defects which may affect the utility of the forgings.

Chemical composition of Nimonic ALloy 75, Nimonic 75, ALloy 75,UNS N06075,nimonic75 forging turbine parts is as

The chemical composition of NIMONIC 75 is as follows:

Carbon ........................................................................0.08-0.15

Chromium....................................................................18.0-21.0

Copper..........................................................................0.5 max.

Iron................................................................................5.0 max.

Manganese ...................................................................1.0 max.

Silicon ...........................................................................1.0 max.

Titanium...........................................................................0.2-0.6

Nickel............................................................................Balance

mechanical property of for Nimonic ALloy 75, Nimonic 75, ALloy 75,UNS N06075,nimonic75 forged round bars is as follow

Properties Metric Imperial

Tensile strength(annealed) 750 MPa 109 ksi

Yield strength(annealed) 275 MPa 40 ksi

Elongation at Break 42% 42%

Modulus of Elasticity 206 GPa 29878 ksi

.

The purity grade of the Nimonic ALloy 75, Nimonic 75, ALloy 75,UNS N06075,nimonic75 forged steel material is to be determined per DIN 50602-K1.The following value is to be kept in this case(on 1000 mm²)-Sum characteristics value K1:≤2.0

For determination 4 tests per heat are to be employed at least Depending on the appearance of the analysed microsections also higher K1-Values may possibly be Tolerated.Content of Delta-Ferrite Delta ferrite content:<5% (Determined in a manner consistent with the evaluation technique described in ASTM E 45/Method A,"Worst Field Method"at V=100,specimen orientation:longitudinal.Thedistribution and size of delta ferrite must be such that it does not result in indication in magnetic particle testing of the ready-machined surface.)

The following NDT inspections shall be performed after all heat treatments are performed

Visual inspection of all Nimonic ALloy 75, Nimonic 75, ALloy 75,UNS N06075,nimonic75 forging round bars

UT of all imonic ALloy 75 flat bars as per SEP 1923,inspection number D3 or D2 with dual (twin crystal search unit.100% of the volume shall be examined with the stipulated ecording level

Criteria stipulated in SEP 1923 quality class 2 b shall be applied with following modification:EE(single echo)and VE(numerous single echoes)without extension ≥2mm KSR are not permitted Defects above the recording limit shall be marked and it shall be ensured that these Nimonic 75 forging flat bars are not included in the lot delivered.

Welcome your inquiry of Nimonic ALloy 75, Nimonic 75, ALloy 75,UNS N06075,nimonic75 forging parts