Description

Jiangsu Liangyi professional manufacturer of Monel 400,Monel Alloy 400, ALloy 400,UNS N04400 open die forging parts and seamless rolled steel forged rings from china

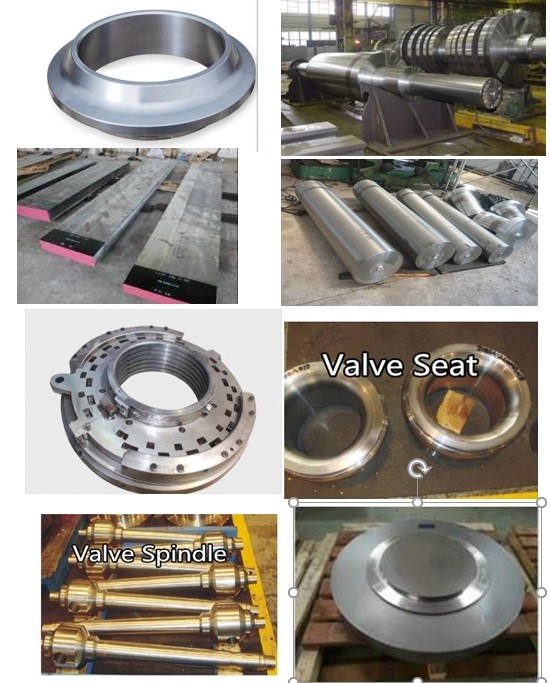

Following is the shape of Monel 400,Monel Alloy 400, ALloy 400,UNS N04400 forging steel material that we could do is:Monel 400 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Monel Alloy 400 Forged forging steel rings seamless rolled rings,ALloy 400 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,UNS N04400 Forged Forging Steel Discs Disks Blocks plates,Monel 400 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of Monel 400,Monel Alloy 400, ALloy 400,UNS N04400 material that is used in following industry

Monel 400 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

Monel Alloy 400 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

ALloy 400 Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

Monel 400 forged steel Mechanical Seal Discs

Monel Alloy 400 Forged Forging Steel Butterfly Valve Main Shafts Spindles

UNS N04400 Forged Forging Marine Ship Boat Propeller Shafts

ALloy 400 Forged Forging Swept branches outlets steel fittings swept saddles

Monel 400 Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

Monel 400 Forged Forging Gas Air Compressor Rotor

Monel Alloy 400 Forged Forging Steels Christmas Trees wellhead Spool Body Bodies cylinder

ALloy 400 Forged Forging venturi cone meter Body Bodies Blocks

UNS N04400 Forged Forging Steel gate valves Body Bodies bespoke flat bars

Monel 400 forging forged steel Couplings

Monel 400 forged steel Flowseal cryogenic High Performance BV Butterfly Valves HPBV shaft

Monel 400 forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

Monel Alloy 400 Forged Forging Steel double studded adapter flange

Monel Alloy 400 Forged Forging Steel integral Mud Flange Flanged outlet Studded crosses

UNS N04400 Forged Forging Steel Casing Heads,Tubing Heads,Casing Hangers,Tubing Hangers,Tubing Spools,Casing Spools,Spacer Spools

Monel Alloy 400 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

Monel Alloy 400 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

Monel Alloy 400 Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

Monel Alloy 400 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

Alloy 400 Forged Forging forge Steel transition Cone

UNS N04400 Forged Forging Steel Pressure Vessel Reactor Nozzles

Monel Alloy 400 is s a solid-solution alloy thatcan be hardened only by cold working. It has high strength and toughness over a wide temperature range and excellent resistance to many corrosive environments.

Alloy 400 is widely used in many fields, especially marine and chemical processing. Typical applications are valves and pumps; pump and propeller shafts;marine fixtures and fasteners; electrical and electronic components; springs; chemical processing equipment; gasoline and fresh water tanks; crude petroleum stills, process vessels and piping; boiler feedwater heaters and other heat exchangers; and deaerating heater.

FOllowing is chemical compostion of Monel Alloy 400 forged steel rings

C: 0.03 max

Mn: 2.00 max

Si: 0.5 max

S: 0.024 max

Cu: 28.0 – 34.0

Ni: 63.0 – 70.0

Fe: 2.5 max

FOllowing is forging methods of heat treatment methods of monel 400 forged steel rings, :

Alloy 400 forged material can be annealed or stress relieved for the desired combination of strength and ductility and to minimized distortion during subsequent machining.

Annealing

Heating should be done in a sulfur-free reducing atmosphere. The annealing range is 1300 to 1800°F, however 1600 to 1800°F is most typical. The lower annealing temperatures (e.g. 1300 to 1500°F) can be utilized with longer times at temperature to minimize grain coarsening.

Stress Relieving

Stress relieving will reduce stresses without recrystallizing the grain structure. Heating to 1000/1050°F for 1 to 2 hours will relieve strains in monel 400 forging parts

Following of Monel 400 forging parts heat treatment Delivery condition :

Properties Metric Imperial

Tensile strength(annealed) 517-620 MPa 75-90 ksi

Yield strength 172-345 MPa 25-50 ksi

Modulus of elasticity 179 GPa 26000 ksi

Poisson’s ratio 0.32 0.32

All our forged Monel 400,Monel Alloy 400, ALloy 400,UNS N04400 forged shafts can be release en10204-3.1 certificate, or en10204-3.2 inspection certificate from following third party,3.2 mit TUV ,GL BV,DNV,ABS ,Lloyds Register of Shipping, RMRS ,RINA and so on

The following details shall be furnished in the test certificate of finished Monel 400 forged steel:

Heat No. , and melting type.

Dimensional inspection

Details of heat treatment cycle followed.

Results of chemical analysis including tramp elements.

Results of mechanical tests, including hardness test. All individual values shall be reported.Results of ultrasonic tests

Results of surface crack examination

Confirmation of the visual inspection

Confirmation of the verification inspection

Results of additional tests called for in the drawing/order.

Welcome your inquiry of Monel 400,Monel Alloy 400, ALloy 400,UNS N04400) forging forged steel parts