Description

Jiangsu Liangyi is professional manufacturer of AISI 316L MOD,UREA 316L Modified,316L Mod,Grade 724L open die forging parts and seamless rolled steel forged rings from china

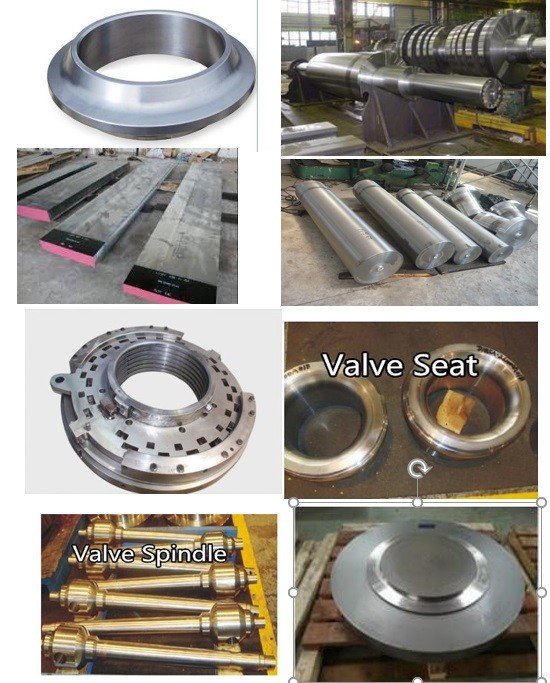

Following is the shape of AISI 316L MOD,UREA 316L Modified,316L Mod,Grade 724L forging steel material that we could do is: AISI 316L MOD Forged Steel round bars square bars Flat bars Rectangles Bars Rods,AISI 316L MOD Forged forging steel rings seamless rolled rings,UREA 316L Modified Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,UREA 316L Modified Forged Forging Steel Discs Disks Blocks plates,AISI 316L MOD Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of AISI 316L MOD,UREA 316L Modified,316L Mod,Grade 724L material that is used in following industry

Grade 724L Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

UREA 316L Modified Forged Forging Steel nuclear Power

Grade 724L Forged Forging Steel Butterfly Valve Main Shafts Spindles

UREA 316L Modified Forged Forging Swept branches outlets steel fittings swept saddles

AISI 316L MOD Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

AISI 316L MOD Forged Forging Steels Christmas Trees wellhead Spool Body Bodies cylinder

Grade 724L Forged Forging venturi cone meter Body Bodies Blocks

UREA 316L Modified Forged Forging Steel gate valves Body Bodies bespoke flat bars

AISI 316L MOD forged steel Flowseal cryogenic High Performance BV Butterfly Valves HPBV shaft

Grade 724L forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

AISI 316L MOD Forged Forging Steel double studded adapter flange

AISI 316L MOD Forged Forging Steel integral Mud Flange Flanged outlet Studded crosses

UREA 316L Modified Forged Forging Steel Casing Heads,Tubing Heads,Casing Hangers,Tubing Hangers,Tubing Spools,Casing Spools,Spacer Spools

AISI 316L MOD Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

Grade 724L Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

Duplex Stainless Steel 2205 Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

AISI 316L MOD Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

UREA 316L Modified Forged Forging forge Steel transition Cone

UREA 316L Modified Forged Forging Steel Pressure Vessel Reactor Nozzles

AISI 316L MOD forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

AISI 316L MOD is is modified 316L, which is the AISI standard grade of the United States. Urea-grade ultra-low carbon stainless steel is a modified 316L, which belongs to austenite-ferrite duplex stainless steel. It is specially used in the urea industry, so it is called urea-grade 316L.

Because of its excellent welding hot crack resistance and intergranular corrosion resistance, it is commonly used as a high-pressure pipeline material for petrochemical urea plants.

Urea-grade stainless steel is a kind of austenitic stainless steel specially used in the urea production process. In the production process of urea, intermediate products such as ammonium carbamate have strong corrosion to stainless steel. Generally, stainless steel, such as 316L, cannot meet its corrosion resistance requirements.

FOllowing is chemical compostion of AISI 316L MOD,Grade 724L forged steel rings

C ≤0.03

Si ≤1.000

Mn ≤2.00

P ≤0.04

S ≤0.030

Cr 17-18.5

Ni 13-15

Mo 2.2-3

N ≤0.22

Fe ≤0.6

Macrostructure of AISI 316L MOD forging steel [arts is as follow

Visual examination of transverse full cross-sections from AISI 316L MOD forged bars, billets, and stock for AISI 316L MOD forging, AISI 316L MOD forged rings, orextrusions, etched in hot hydrochloric acid in accordance with ASTM A 604, shall show no pipe or cracks. Porosity,segregation, inclusions, and other imperfections shall be no worse than the macrographs of ASTM A 604

- MACROSTRUCTURE LIMITS of AISI 316L MOD forging materialis as follow

Class Condition Severity

1 Freckles A

2 White Spots A

3 Radial Segregation A

4 Ring Pattern B

Following of AISI 316L MOD,Grade 724L forging parts heat treatment nechanical property Delivery condition :

Hardness HB 30 0.2% ≤ HB215

Yield strength Rp ≥200MPA

Tensile strength Rm ≥500-700MPA

Elongation A5 ≥30

ALl our AISI 316L MOD,Grade 724L forged shall maintain a complete record of all stages of processing during the manufacture of each forging.Information from these records shall be made available on request for a period of not less than 10 years.

WE shall furnish for each shipment three (3)copies of a dated certified test report,which include the following information:

a.Purchase Agreement Number.

b.PDS Specification and Revision Number.

c.Drawing Number,including Item Number and Issue Number.

d.Total Number of parts per shipment.

e.Heat Number.

f.Raw material source and manufacturing processes and procedures used to produce parts to this specification

g.Heat Treat Temperatures and Holding Times (Heat Treatment Chart)

h.Chemical Composition of each Heat

i.Chemical Composition of each Forging.

j.Tensile Properties of each forging.

k.Results of Creep Rupture Test

l.Hardness of each Forging.

m.Results of Macro Etch Examination (including photographs).

n.Results of Microstructure Examination (including photomicrographs).

o.Results of Nondestructive Examination.

p.Forging Number and Test Number.

q.NCR number,when applicable.

r.Name of Manufacturer.

s.A statement that the forgings conform to all the requirements of this specification,a statement of any deviation applying to the shipment which has received written approval from the Purchaser.A copy of the document approving the deviationshall be attached to the test report.

NOTE:All test results shall be identified with respect to location of test specimens.

Welcome your inquiry of AISI 316L MOD,UREA 316L Modified,316L Mod,Grade 724L forging forged steel parts