Description

Jiangsu Liangyi professional manufacturer of AMS 5887 open die forging parts and seamless rolled steel forged rings from china

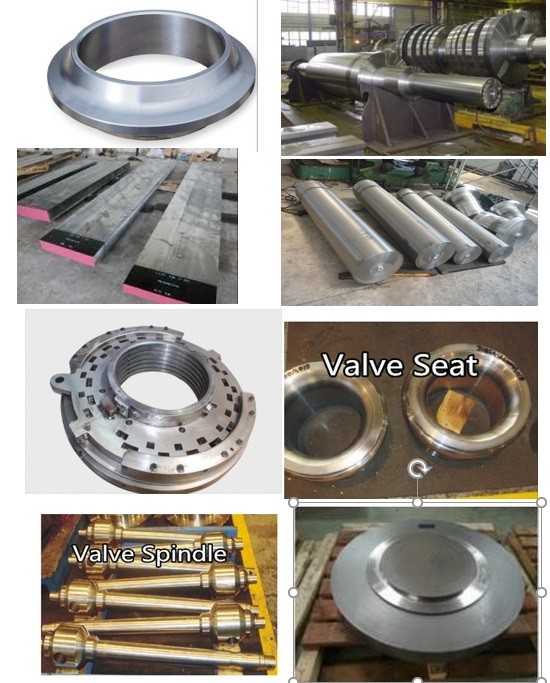

Following is the shape of AMS 5887 forging steel material that we could do is:AMS 5887 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,AMS 5887 Forged forging steel rings seamless rolled rings,AMS 5887 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,AMS 5887 Forged Forging Steel Discs Disks Blocks plates,AMS 5887 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of AMS 5887 material that is used in following industry

AMS 5887 Forged Forging Turbine and Compressor Labyrinth Shaft Seals

AMS 5887 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

AMS 5887 Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

AMS 5887 Forged Forging venturi cone meter Body Bodies Blocks

AMS 5887 Forged Forging Steel gate valves Body Bodies bespoke flat bars

AMS 5887 forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

AMS 5887 Forged Forging Steel double studded adapter flange

AMS 5887 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

AMS 5887 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

AMS 5887 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

AMS 5887 Forged Forging forge Steel transition Cone

AMS 5887 Forged Forging Steel Pressure Vessel Reactor Nozzles

AMS 5887 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

AMS 5887 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs,turbine wheel discs

AMS 5887 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

AMS 5887 Forging Steel gas steam Turbine Guide Rings,Turbine shroud rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

AMS 5887 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

AMS 5887 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

AMS 5887 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

AMS 5887 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

AMS 5887 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

AMS 5887 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

AMS 5887 is a nickel-chromium-cobalt-molybdenum alloy with an exceptional combination of metallurgical stability, strength and oxidation resistance at high temperatures. Resistance to oxidation is enhanced by an aluminum addition. The alloy also resists a wide range of corrosive aqueous environments. Used in gas turbines for combustion cans, ducting and transition liners; petrochemical processing; heat-treating equipment; and in nitric acid production.

All our AMS 5887 forged material must give the material a required purity necessary for the application in following melting methods one is triple melted material,VIM+ESR+VAR., the another one is double melted material,VIM+VAR.

The forging ratio of all our AMS 5887 forged bars is minimum 3:1

FOllowing is chemical compostion of AMS 5887 forged steel rings

Carbon (C) 0.05 to 0.15 %

Nickel(Ni) Rem %

Iron (Fe) 3 %

Silicon (Si) 0.50 %

Manganese (Mn) 0.50 %

Cobalt (Co) 10 to 15 %

Chromium (Cr) 20 to 24 %

Titanium (Ti) 0.60 %

Phosphorous (P) 0.015 %

Sulfur (S) 0.015 %

Molybdenum (Mo) 8 to 10 %

Aluminum (Al) 0.80 to 1.50 %

Following of AMS 5887 forging parts heat treatment nechanical property Delivery condition :

Ultimate Tensile Strength: 95 KSI min (655 MPa min)

Yield Strength: 35 KSI min (241 MPa min )

Elongation: 30% min

We have following forging production equipment for all our AMS 5887 forging steel parts

6 mobile hearth heating furnaces with a loading capacity of 10t up to 80t, equipped with a centralized automatic controlled system of the heating cycles;

a 6.300 tons semiautomatic hydraulic press;

a 3.500 tons semiautomatic hydraulic press;

a 70 tons capacity manipulator;

a 36 tons capacity manipulator;

a 24 tons capacity manipulator;

a 12 tons manipulator on rails.

Following is all testing report that we supply for AMS 5887 forged parts

1. Chemical composition The same furnace

2. Mechanical nature "The test which picks one set in the same furnace,the

same heat treatment,(The test piece extracts from

one in two)"

Hardness measurement All

4. Dimension inspection All

5. Appearance inspection All

6. Ultrasonic crack test All

7. Osmosis crack test All

8. Magnetic permeability Test All

Welcome your inquiry of AMS 5887 forging forged steel parts

Following is the shape of AMS 5887 forging steel material that we could do is:AMS 5887 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,AMS 5887 Forged forging steel rings seamless rolled rings,AMS 5887 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,AMS 5887 Forged Forging Steel Discs Disks Blocks plates,AMS 5887 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of AMS 5887 material that is used in following industry

AMS 5887 Forged Forging Turbine and Compressor Labyrinth Shaft Seals

AMS 5887 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

AMS 5887 Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

AMS 5887 Forged Forging venturi cone meter Body Bodies Blocks

AMS 5887 Forged Forging Steel gate valves Body Bodies bespoke flat bars

AMS 5887 forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

AMS 5887 Forged Forging Steel double studded adapter flange

AMS 5887 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

AMS 5887 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

AMS 5887 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

AMS 5887 Forged Forging forge Steel transition Cone

AMS 5887 Forged Forging Steel Pressure Vessel Reactor Nozzles

AMS 5887 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

AMS 5887 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs,turbine wheel discs

AMS 5887 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

AMS 5887 Forging Steel gas steam Turbine Guide Rings,Turbine shroud rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

AMS 5887 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

AMS 5887 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

AMS 5887 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

AMS 5887 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

AMS 5887 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

AMS 5887 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

AMS 5887 is a nickel-chromium-cobalt-molybdenum alloy with an exceptional combination of metallurgical stability, strength and oxidation resistance at high temperatures. Resistance to oxidation is enhanced by an aluminum addition. The alloy also resists a wide range of corrosive aqueous environments. Used in gas turbines for combustion cans, ducting and transition liners; petrochemical processing; heat-treating equipment; and in nitric acid production.

All our AMS 5887 forged material must give the material a required purity necessary for the application in following melting methods one is triple melted material,VIM+ESR+VAR., the another one is double melted material,VIM+VAR.

The forging ratio of all our AMS 5887 forged bars is minimum 3:1

FOllowing is chemical compostion of AMS 5887 forged steel rings

Carbon (C) 0.05 to 0.15 %

Nickel(Ni) Rem %

Iron (Fe) 3 %

Silicon (Si) 0.50 %

Manganese (Mn) 0.50 %

Cobalt (Co) 10 to 15 %

Chromium (Cr) 20 to 24 %

Titanium (Ti) 0.60 %

Phosphorous (P) 0.015 %

Sulfur (S) 0.015 %

Molybdenum (Mo) 8 to 10 %

Aluminum (Al) 0.80 to 1.50 %

Following of AMS 5887 forging parts heat treatment nechanical property Delivery condition :

Ultimate Tensile Strength: 95 KSI min (655 MPa min)

Yield Strength: 35 KSI min (241 MPa min )

Elongation: 30% min

We have following forging production equipment for all our AMS 5887 forging steel parts

6 mobile hearth heating furnaces with a loading capacity of 10t up to 80t, equipped with a centralized automatic controlled system of the heating cycles;

a 6.300 tons semiautomatic hydraulic press;

a 3.500 tons semiautomatic hydraulic press;

a 70 tons capacity manipulator;

a 36 tons capacity manipulator;

a 24 tons capacity manipulator;

a 12 tons manipulator on rails.

Following is all testing report that we supply for AMS 5887 forged parts

1. Chemical composition The same furnace

2. Mechanical nature "The test which picks one set in the same furnace,the

same heat treatment,(The test piece extracts from

one in two)"

Hardness measurement All

4. Dimension inspection All

5. Appearance inspection All

6. Ultrasonic crack test All

7. Osmosis crack test All

8. Magnetic permeability Test All

Welcome your inquiry of AMS 5887 forging forged steel parts