Description

Jiangsu Liangyi professional manufacturer of 23H12MNF open die forging parts and seamless rolled rings factory from china

23H12MNF is a tempered stainless, high-temperature chromium steel with molybdenum addition, which is used as a standard steel for components in steam turbines and high-temperature bolts. The vanadium addition increases the creep and creep rupture strength. Scale resistance up to approx. 600°C is given.

Its application owes to its high resistance to fatigue stress. 23H12MNF also features elements and parts of aircraft construction,

components in the chemical, petrochemical and petrochemical industries, as well as parts used in the power industry.

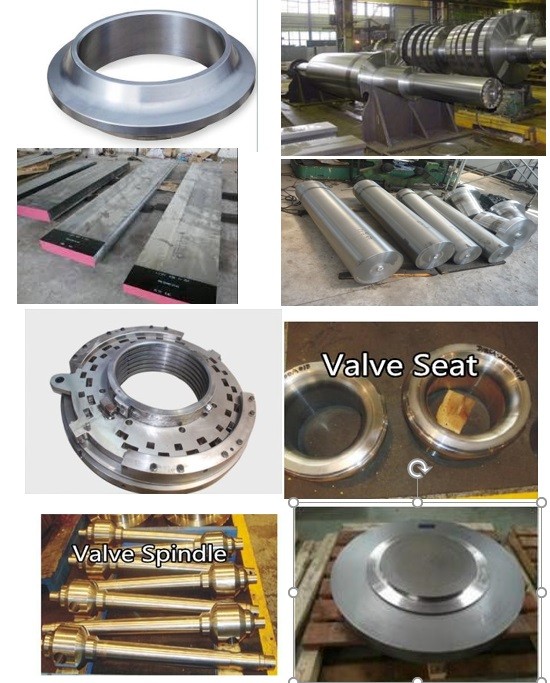

Following is the shape of 23H12MNF forging steel material that we could do is:23H12MNF Forged Steel round bars square bars Flat bars Rectangles Bars Rods,23H12MNF Forged forging steel rings seamless rolled rings,23H12MNF Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,23H12MNF Forged Forging Steel Discs Disks Blocks plates,23H12MNF Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.23H12MNF Forged Forging Steel Gas Steam Turbine Rotors Shafts,23H12MNF Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars,23H12MNF Forged Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings,, Z20CDNbV11 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,,23H12MNF Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

As per forging of 23H12MNF material, we have 1 tons,3 tons,6 tons,9 tons forging hammer and 4500 tons hydraulic press,and 3 metres and 6 metre seamless rolled rings machine

Following is our forging capacity for 23H12MNF forging steel parts

23H12MNF turbine blade Flat bars: from 90x60 mm to 1800x500 mm or 1200x800 mm or 1600x600 mm, length: 2000 - 12000 mm, max.

23H12MNF Forgings: max. dia.:Ø 2150 mm, max. length: 12 000 mm, max. weight of a forging: 30 000 kg,

23H12MNF forging Discs: max. external dia.: Ø 2500 mm, max. borehole dia.: o 1800 mm, max. weight: 28 000 kg

We could supply 23H12MNF forging turbine material as per the standard of EN10204-3.1 or EN10204-3.2 of third party such TUV, DNV,BV,SGS and so on

Following is production process for 23H12MNF forged Turbine Blades steel Flat Bars

Main Production Process: steel melting—ingots—forging—UT—rough machining—quenching&tempering—semi finish machining—finish machining—packaging and shippment

We produce 23H12MNF forged steel turbine blade material as per standard of NF A 35-558-1983

C:0.20 - 0.26

Mn:0.3 - 0.8

Si:0.1 - 0.5

P:<0.035

S:<0.035

Cr:11.0 - 12.5

Mo:0.8 - 1.2

Ni:0.3 - 0.8

V:0.25 - 0.35

Nb:0.05

W:0.6

Following is mechnical property of 23H12MNF forged turbine blade flat bars Rectangles Bars

Tensile strength Rm = 800 - 950 MPa

Yield point Re > 600 MPa

Elongation A > 14%

reduction Z > 40%

Notch toughness KV > 27 J

We have following inspection equipment to inspect 23H12MNF forging steel parts

Brinell hardness testing for 23H12MNF forging parts

Testing of mechanical properties by low and high temperatures for 23H12MNF forging parts

metallography for 23H12MNF forging parts

defectoscopy for 23H12MNF forged parts

visual testing, dimensional testing for 23H12MNF forging products

UT testing per EN 10228-3 (up to level 4) for 23H12MNF forging material

MT testing per EN 10228-1 (up to level 4) for 23H12MNF forging parts

Welcome your inquiry of 23H12MNF forging forged steel parts