Description

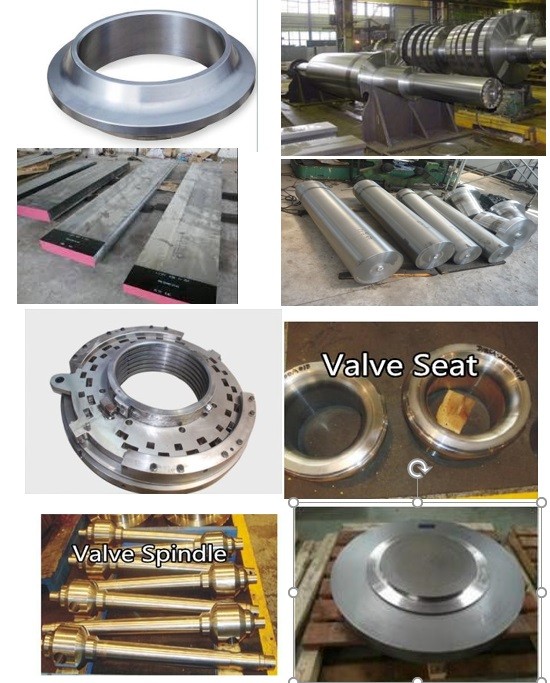

Jiangsu Liangyi is professional manufacturer of 1.6368,15NiCuMoNb5-6-4,15NiCuMoNb564,15NiCuMoNb5.6.4 open die forging parts and seamless rolled steel forged rings,forged pipes tubes,forging steel valve body valve closure valve stems valve bonnet valve body valve seat rings from china

Following is the shape of 1.6368,15NiCuMoNb5-6-4,15NiCuMoNb564,15NiCuMoNb5.6.4 forging steel material that we could do is:1.6368 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,15NiCuMoNb5.6.4 Forged forging steel rings seamless rolled rings,15NiCuMoNb5-6-4 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,15NiCuMoNb5.6.4 Forged Forging Steel Discs Disks Blocks plates,15NiCuMoNb564 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of 1.6368,15NiCuMoNb5-6-4 that is used in following industry

1.6368,15NiCuMoNb5-6-4 forged forging steel valve body,valve bonnet.valve closure, valve seat rings, valve stems, valve discs disks for High pressure gate valves,High pressure globe valves, High Pressure Swing Check valve,High pressure valves steam turbine power valves, GAs TURBINE BYPASS VALVE,Line blind valves,Preheater bypass valve

1.6368 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets, nozzles, channel flanges for boiler, heat exchanger,pressure vessel

1.6368 forging/forged Steel Lateral Tees T-piece Wyes( Lateral Y-Piece, Eccentric Lateral Tee)

1.6368 Forged Forged Pumps suction side sealing jacket seal chambers jacket casings

15NiCuMoNb5-6-4 Forged Forging Swivel Ring Flanges

15NiCuMoNb5-6-4 Forging/Forged Forge Steel Wye Piece/Piggable Wyes

1.6368 Forged Forging Swept branches outlets steel fittings swept saddles

15NiCuMoNb5-6-4 Forged Forging Steel double studded adapter flange

15NiCuMoNb5.6.4 Forged Forging venturi cone meter Body Bodies Blocks

15NiCuMoNb5-6-4 forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

15NiCuMoNb564 Forged Forging Steel double studded adapter flange

15NiCuMoNb564 Forged Forging Steel integral Mud Flange Flanged outlet Studded crosses

15NiCuMoNb564 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

15NiCuMoNb564 Forged Forging Steel Pressure Vessel STUDDING OUTLET

15NiCuMoNb5-6-4 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings

15NiCuMoNb5.6.4 Forged Forging forge Steel transition Cone

1.6368,15NiCuMoNb5-6-4 is Low-alloy steel with copper additive for use at elevated temperatures up to 500 ℃. Products in this steel grade are produced in the form of hot rolled sheets, seamless pipes, hot-rolled and forged bars.This steel, unlike other grades, has an increased content of nickel and copper. It is used in the construction of boilers for boiler drums, which work up to 375 ℃, high-pressure boilers, pressure vessels, pipelines, nuclear reactors evaporators, chemical apparatus, and other power equipment.

STEEL MAKING of 1.6368,15NiCuMoNb5-6-4 forging parts

The steel shall be produced by an electric furnace process or one of the basic oxygen processes. The steel shall be fully killed. The steel products shall be forged or rolled.

FOllowing is chemical compostion of 1.6368 forging shells

The chemical composition of the material shall comply with the table below:

|

|

Percentage of mass [%] |

||||||||||||

|

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Cu |

Mo |

Nb |

N |

Al |

||

|

Ladle Analysis |

Min. |

0,10 |

0,25 |

0,80 |

--- |

--- |

-- |

1,00 |

0,50 |

0,25 |

0,015 |

--- |

0,015 |

|

Max. |

0,17 |

0,50 |

1,20 |

0,025 |

0,020 |

0,30 |

1,30 |

0,80 |

0,50 |

0,045 |

0,020 |

0,050 |

|

|

Part Analysis |

Min. |

0,08 |

0,20 |

0,75 |

--- |

--- |

--- |

0,95 |

0,45 |

0,22 |

0,010 |

--- |

0,010 |

|

Max. |

0,19 |

0,56 |

1,30 |

0,030 |

0,025 |

0,35 |

1,35 |

0,85 |

0,54 |

0,050 |

0,022 |

0,060 |

|

Mechanical properties of 1.6368 forging parts

. Guaranteed mechanical properties at room temperature

|

Thickness tR [mm] |

Direction of test piece |

ReH [MPa] 2) |

Rm [MPa] 3) |

A [%] |

|

≤ 800 |

transverse (Q) / tangential (T) |

430 |

580 to 740 |

18 |

|

longitudinal (L) |

20 |

|||

|

1) - 2) If upper yield strength (ReH) does not develop, the strength requirements apply to the 0,2 % proof strength (Rp0,2) 3) Rm : Tensile strength |

||||

Guaranteed mechanical properties at elevated temperatures

|

Thickness tR [mm] |

Direction of test piece |

100 |

150 |

Rp0,2 at temperature [°C]

200 |

400 |

450 |

||||||||

|

≤ 800 |

transverse (Q) tangential (T) longitudinal (L) |

402 |

|

[MPa]

363 |

|

294 |

||||||||

|

|

||||||||||||||

Guaranteed impact energy

|

Thickness tR [mm] |

Direction of test piece |

Impact energy KV2 2) at temperature

0°C |

|

|

≤ 800 |

transverse (Q) tangential (T) |

31 J |

40 J |

|

longitudinal (L) |

39 J |

48 J |

|

|

1) - 2) The mean value for a series of three specimens shall meet the specified value. An individual value may be less than the required value on condition it is not below 70% of the specified mean average value. |

|||

Heat treatment way of 1.6368,15NiCuMoNb5-6-4 forging parts

|

Quenching and tempering

Normalizing / Hardening |

Heat treatment after welding and for stress relief annealing |

||

|

880°C to 960°C |

620°C to 680°C |

530°C to 620°C |

|

|

Thickness [mm] |

Duration1) [min] |

||

|

After the temperature is reached in the whole cross-section, cooling in air, oil or water based medium. |

Soaking time according EN ISO 4885 [11] at least 30 min. Cooling on air. |

||

|

≤ 15 |

≥ 15 |

||

|

> 15 to ≤ 30 |

≥ 30 |

||

|

> 30 to ≤ 150 |

about 60 |

||

|

> 150 to ≤ 400 |

about 90 |

||

|

> 400 to ≤ 625 |

about 120 |

||

|

Cooling on air |

|||

|

1) Equalization and holding within the temperature range 530°C to 620°C. Temperature measurement has to be performed on the surface of the part. |

|||

TEST REQUIREMENTS of 1.6368 forged bars

Ladle analysis

A ladle analysis is compulsory.

Hardness test of 1.6368 forging parts

For all products with mass less or equal 1000 kg a hardness test is compulsory. There is no specified minimum requirement for hardness. Actual values shall be recorded.

Volumetric examination of 15NiCuMoNb5-6-4 forging parts

A volumetric examination acc. EN 10228-3 [3] by ultrasonic testing is required for forged parts. Quality class 4 criteria acc. EN10228-3 [3] shall be met.

A volumetric examination acc. EN 10308 [4] by ultrasonic testing is required for rolled bars with diameter ≥ 30 mm. Quality class 4 criteria acc. EN 10308 [4] shall be met.

In both cases, the required scope of inspection is limited to the standard scope.

Surface examination of 15NiCuMoNb5-6-4 forged bars

The surface of the parts shall be examined. Testing shall be done either per magnetic particle inspection acc. EN 10228- 1 [5] (quality class 3) or per penetrant testing acc. EN 10228-2 [6] (quality class 3)

Mechanical testing of of 1.6368,15NiCuMoNb5-6-4 forging material

Test units, location and direction of test samples

For test units, location and direction of the samples, the provisions of EN 10222- 1 [2] shall be applied. The material shall be handled as material according EN10222-2 [7].

Scope of testing 1.6368,15NiCuMoNb5-6-4 forging rings

For each test unit and each testing location the following tests shall be carried out:

Tensile test according EN ISO 6892- 1 [8] (test method A)

Hot tensile test according EN ISO 6892-2 [9] at 350°C

Impact test according EN ISO 148- 1 [10] on 3 Charpy V-notch test samples at 0°C.

MARKING of finished 1.6368,15NiCuMoNb5-6-4 forged parts

All parts shall be marked by stamping or forged in marking. The marking shall include:

Sign of manufacturer

Heat number

Test specimen number

Heat treatment number (if applicable)

Material type: 1.6368 or 15NiCuMoNb5

Serial number (if applicable)

INSPECTION CERTIFICATE of finished 15NiCuMoNb5-6-4 forged bars

A type 3.2 inspection certificate according EN 10204 [13] shall be issued by the material manufacturer for the products. The inspection certificate shall include:

Type of steel making process

Chemical analysis of melting charge

Mechanical test results

Heat treatment conditions including used temperatures

Hardness test (actual hardness value shall be reported)

Report of non-destructive testing (scope according applicable test standards)

Conformity of the product with this specification and order requirements

The inspection certificate is a “documented information” according ISO 9001 [14]. For all documents a document number, a revision status or an index number, a page number and the total number of pages are required. If there are other test records linked to the inspection certificate, e.g. records of non- destructive testing, reports of material laboratories or other documents, these test reports shall be included as appendix in the inspection certificate (including their document number, revision status or index number, page number and total number of pages).

For issuing of the type 3.2 certificate according EN 10204 [13], the following shall be considered:

The manufacturer of the material must be hold an accreditation as material manufacturer according PED 2014/68/EU [1], annex I, chapter 4. The manufacturer´s authorized inspection representative shall be independent of the manufacturing department.

The required third party inspection agency shall be accredited as notified body according PED 2014/68/EU [1]

Welcome your inquiry of 1.6368,15NiCuMoNb5-6-4 forging forged steel parts