Description

Jiangsu Liangyi professional manufacturer of AISI 4145,SAE 4145H,AISI 4145H MOD,AISI 4145H Modified open die forging parts and seamless rolled steel forged rings from china

Following is the shape of AISI 4145,SAE 4145H,AISI 4145H MOD,AISI 4145H Modified forging steel material that we could do is:AISI 4145 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,SAE 4145H Forged forging steel rings seamless rolled rings,AISI 4145 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,AISI 4145 Forged Forging Steel Discs Disks Blocks plates,AISI 415 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of AISI 4145,SAE 4145H,AISI 4145H MOD,AISI 4145H Modified material that is used in following industry

AISI 4145H Modified Forged Forging Steel Mining Mine raise boring machine drill stabilizer /drilling pipe /drill rod/stem bar

AISI 4145H Modified Forged Forging Steel Drill Collars/Drilling Pipes

AISI 4145H Modified Forged Forging Stabilized Roller Reamers Body Bodies

AISI 4145H Forged forging steel Actuactor rings Well casing Swivel rings riser flanges rings

AISI 4145H Forged Forging Steel Raiseboring Raise boring machine Stems

SAE 4145H Forged forging steel Actuactor rings Well casing Swivel rings riser flanges rings

AISI 4145 Forging gearbox,gear reducer gear wheels, pinion shafts,ring gears,Gear shafts.

AISI 4145 forged mud pump, frac pump pinion shafts, bull gears,gear shafts, gear wheels

AISI 4145 Forging Steel Jackup Pinion shafts

AISI 4145 Forged Forged Pumps suction side sealing jacket seal chambers jacket casings

SAE 4145H Forged Forging Swivel Ring Flanges

AISI 4145 Forging/Forged Forge Steel Wye Piece/Piggable Wyes

SAE 4145H Forged Forging Steel double studded adapter flange

SAE 4145 Raiseboring Raise boring machine output spares Float Boxes Spindle Bolts Clamping Rings Range Bodies Spindle Hubs Wrench

AISI 4145 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate pump

AISI 4145 Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

SAE 4145H Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

AISI 4145H MOD Forged Forging Steels Christmas Trees wellhead Spool Body Bodies cylinder

AISI 4145 Forged Forging Block Adaptor

AISI 4145 Forged Forging venturi cone meter Body Bodies Blocks

AISI 4145 Forged Forging Steel frac pumps Fluid End Body Bodies Blocks Modules

AISI 4145H MOD Forged Forging Steel gate valves Body Bodies bespoke flat bars

AISI 4145 Forged Forging Steel drill head casings,collars,landing bowls

SAE 4145H forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

AISI 4145 Forged Forging Steel Subsea X Tree high pressure elbow

AISI 4145H MOD forged forging Steel wellhead locknut Venturi Bench

AISI 4145 Forged Forging Steel double studded adapter flange

AISI 4145 Forged Forging Steel integral Mud Flange Flanged outlet Studded crosses

SAE 4145H Forged Forging Steel Casing Heads,Tubing Heads,Casing Hangers,Tubing Hangers,Tubing Spools,Casing Spools,Spacer Spools

AISI 4145H MOD forging Forging/Forged Steel Wellhead Christmas Tree Frac Head (Fracturing Head)

AISI 4145 Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

AISI 4145 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings

AISI 4145 Forged Forging forge Steel transition Cone

SAE 4145H Forged Forging Blowout Preventer RAM Annular dual Bops Body Bodies Block

AISI 4145 is a chromium – molybdenum low alloy tempered steel. It has improved hardenability and is more is commonly used in the high strength condition with minimum yield 125 ksi / 110 ksi.

AISI 4145H is a low alloy steel suitable for downhole drilling tools such as subs, x-overs, drill collars, pup-joints and fishing tools. General engineering applications include components exposed to heavy strain, such as shafts, gear, bolts etc. AISI 4145H can also be used in hardened condition as machine parts exposed to heavy wear.

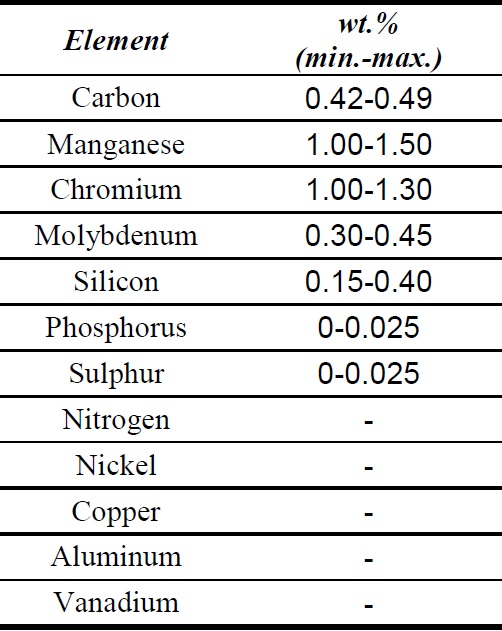

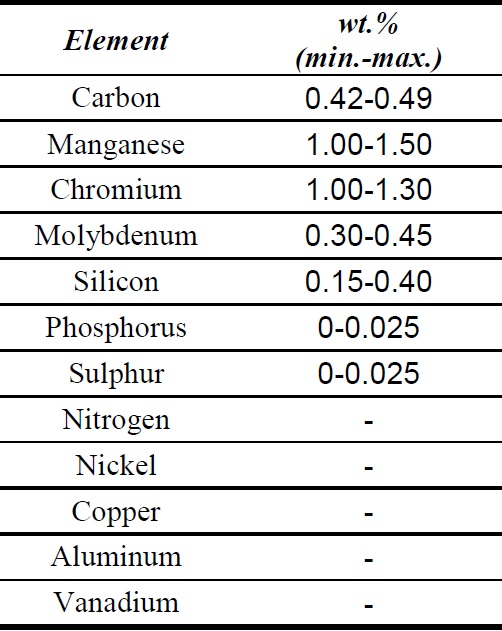

Composition Chemical Analysis of AISI 4145H MOD forged material

The chemical analysis shall be nominally that of AISI 4145H Modified material. Typical chemistry to achieve the mechanical properties are shown below.

Steel Processing Melting of AISI 4145 Forged parts

Metal Cleanliness of AISI 4145H forged bars

Inclusion content must classify 3 heavy sulfide type, 3 heavy alumina type, 3 heavy silica

type, 4 heavy oxide type or better. JK (Jernkontoret) Chart E45 (ASTM) Plate 1.

Reduction Ratio of AISI 4145H mod forged parts

Must be pressed from 35-inch minimum ingot size and must be press forged (not hammer forged). Forgings must have a minimum reduction ratio of 5:1.

Grain Size of AISI 4145H mod forged bars

Grain size shall be “ASTM 5” or finer as determined by ASTM E112.

Heat treatment of AISI 4145 forged parts

Forgings must be normalized, quenched and tempered.

Preliminary heat treatment of AISI 4145H mod forged bars

Forging must be normalized and tempered to 300 max BHN before rough machining.

Final heat treatment of AISI 4145H forged bars

Forging must be quenched and tempered. Rough machine per supplied process drawings if specified on purchase order

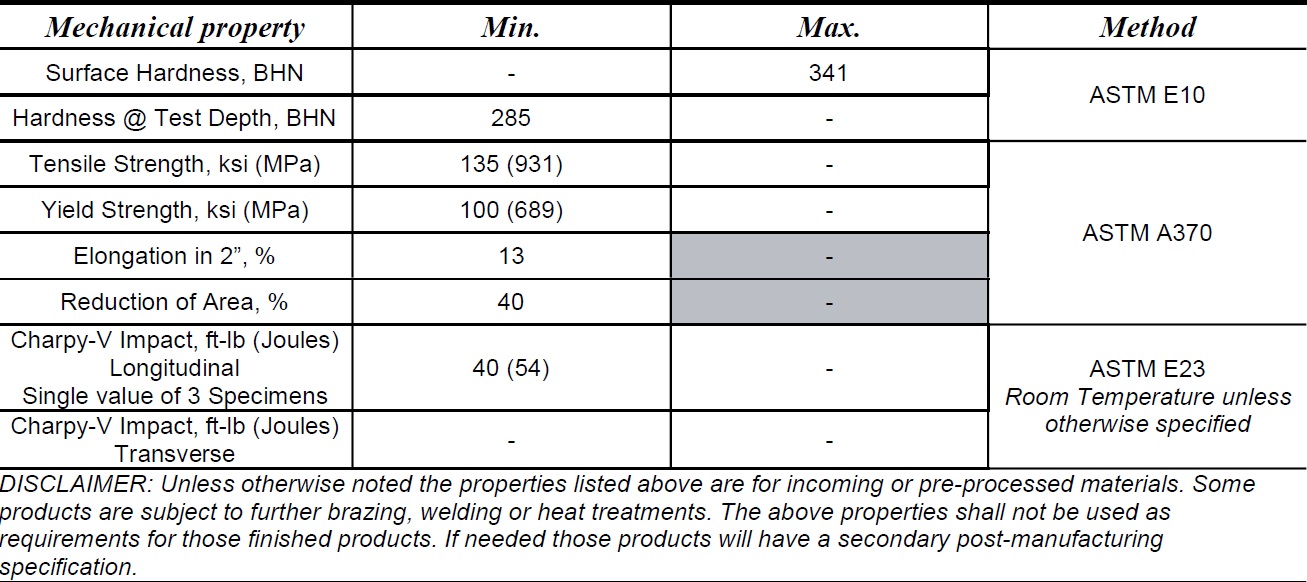

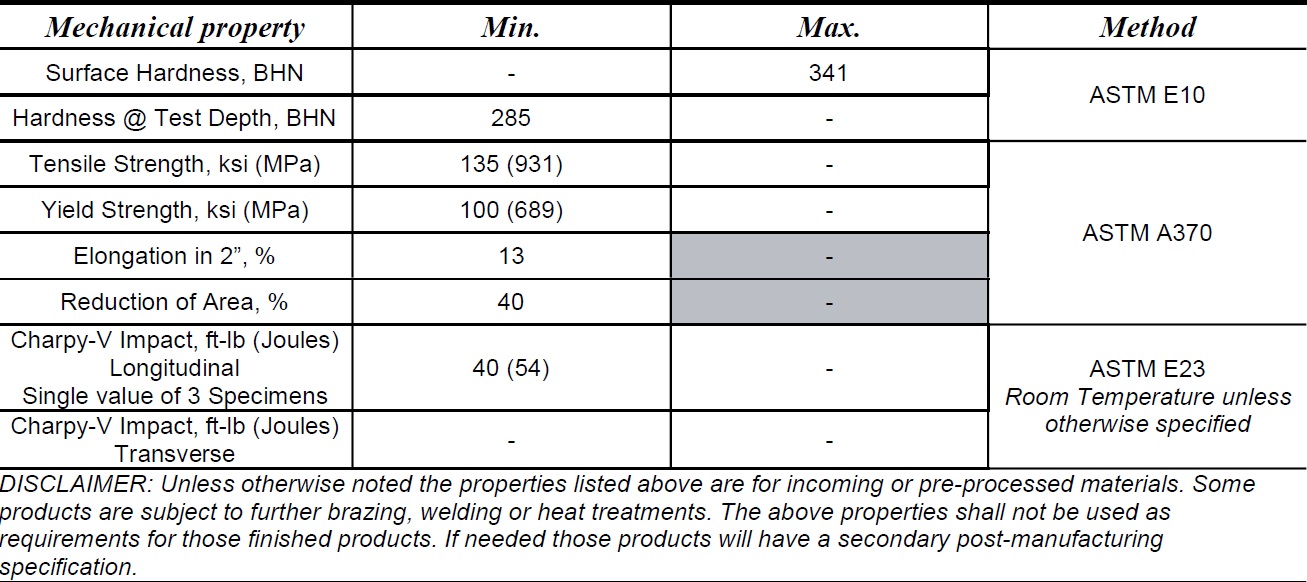

Mechanical Testing Parameters and Frequencies of finished AISI 4145 forged parts

Test sections must not be heat treated separately from product. (12 Inch long one test coupon required per each heat lot). Any single mechanical property test value (Not Average) must meet the above requirements.

Tensile specimens longitudinal; 2" below or mid radius, whichever is closest to the

surface; determined on the basis of one test per ten bodies per heat per heat treat lot.

Impact specimens longitudinal and radially notched; 2" below or mid radius, whichever is

closest to the surface; determined on the basis of one test per ten bodies per heat per heat treat lot. BHN hardness 2" below or mid radius, whichever is closest to the surface; determined on the basis of one test per ten bodies per heat per heat treat lot.

Non-Destructive Examination of AISI 4145H forged parts

Heat treated material shall be ultrasonically inspected per ASTM A388.

The acceptance criteria are ASTM A388, S1. Straight beam only for solid material. Straight beam and angle beam for hollow material.

Dimension/Straightness of finished AISI 4145H Mod forged bars

Straightness: 1/8 inch deviation from straight line in 5-feet.

Surface condition: The typical external surface finish shall be rough turned by the vendor.

Surface imperfections are acceptable if they do not exceed 0.150" maximum depths.

Markings of every pieces of AISI 4145 forged hollow bars

Supplier to hard stencil each body with:

Heat Number

Bar Number

Ingot location, whenever possible and mill practice permit

PO Number

Certification/Documentation of finished AISI 4145H mod forged parts

The supplier shall furnish a certified test report with all requirements per the specification

which includes but is not limited to:

The original mill certificate from the producing mill (melting, grain size,

cleanliness)

Heat Treatment

Heat Number

Lot Number

Chemical composition

Body to furnace lot/load relationship

Mechanical properties

Hardness of each body

Ultrasonic examination results

Welcome your inquiry of AISI 4145H MOD forged parts

Following is the shape of AISI 4145,SAE 4145H,AISI 4145H MOD,AISI 4145H Modified forging steel material that we could do is:AISI 4145 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,SAE 4145H Forged forging steel rings seamless rolled rings,AISI 4145 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,AISI 4145 Forged Forging Steel Discs Disks Blocks plates,AISI 415 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of AISI 4145,SAE 4145H,AISI 4145H MOD,AISI 4145H Modified material that is used in following industry

AISI 4145H Modified Forged Forging Steel Mining Mine raise boring machine drill stabilizer /drilling pipe /drill rod/stem bar

AISI 4145H Modified Forged Forging Steel Drill Collars/Drilling Pipes

AISI 4145H Modified Forged Forging Stabilized Roller Reamers Body Bodies

AISI 4145H Forged forging steel Actuactor rings Well casing Swivel rings riser flanges rings

AISI 4145H Forged Forging Steel Raiseboring Raise boring machine Stems

SAE 4145H Forged forging steel Actuactor rings Well casing Swivel rings riser flanges rings

AISI 4145 Forging gearbox,gear reducer gear wheels, pinion shafts,ring gears,Gear shafts.

AISI 4145 forged mud pump, frac pump pinion shafts, bull gears,gear shafts, gear wheels

AISI 4145 Forging Steel Jackup Pinion shafts

AISI 4145 Forged Forged Pumps suction side sealing jacket seal chambers jacket casings

SAE 4145H Forged Forging Swivel Ring Flanges

AISI 4145 Forging/Forged Forge Steel Wye Piece/Piggable Wyes

SAE 4145H Forged Forging Steel double studded adapter flange

SAE 4145 Raiseboring Raise boring machine output spares Float Boxes Spindle Bolts Clamping Rings Range Bodies Spindle Hubs Wrench

AISI 4145 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate pump

AISI 4145 Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

SAE 4145H Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

AISI 4145H MOD Forged Forging Steels Christmas Trees wellhead Spool Body Bodies cylinder

AISI 4145 Forged Forging Block Adaptor

AISI 4145 Forged Forging venturi cone meter Body Bodies Blocks

AISI 4145 Forged Forging Steel frac pumps Fluid End Body Bodies Blocks Modules

AISI 4145H MOD Forged Forging Steel gate valves Body Bodies bespoke flat bars

AISI 4145 Forged Forging Steel drill head casings,collars,landing bowls

SAE 4145H forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

AISI 4145 Forged Forging Steel Subsea X Tree high pressure elbow

AISI 4145H MOD forged forging Steel wellhead locknut Venturi Bench

AISI 4145 Forged Forging Steel double studded adapter flange

AISI 4145 Forged Forging Steel integral Mud Flange Flanged outlet Studded crosses

SAE 4145H Forged Forging Steel Casing Heads,Tubing Heads,Casing Hangers,Tubing Hangers,Tubing Spools,Casing Spools,Spacer Spools

AISI 4145H MOD forging Forging/Forged Steel Wellhead Christmas Tree Frac Head (Fracturing Head)

AISI 4145 Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

AISI 4145 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings

AISI 4145 Forged Forging forge Steel transition Cone

SAE 4145H Forged Forging Blowout Preventer RAM Annular dual Bops Body Bodies Block

AISI 4145 is a chromium – molybdenum low alloy tempered steel. It has improved hardenability and is more is commonly used in the high strength condition with minimum yield 125 ksi / 110 ksi.

AISI 4145H is a low alloy steel suitable for downhole drilling tools such as subs, x-overs, drill collars, pup-joints and fishing tools. General engineering applications include components exposed to heavy strain, such as shafts, gear, bolts etc. AISI 4145H can also be used in hardened condition as machine parts exposed to heavy wear.

Composition Chemical Analysis of AISI 4145H MOD forged material

The chemical analysis shall be nominally that of AISI 4145H Modified material. Typical chemistry to achieve the mechanical properties are shown below.

Steel Processing Melting of AISI 4145 Forged parts

Steel shall be melted fine grain, aluminum killed.

Steel is manufactured via Electric Arc Furnace, followed by Ladle Refining and Vacuum Degassing and is either cast into bottompoured wide end up ingots, or Continually Cas

Metal Cleanliness of AISI 4145H forged bars

Inclusion content must classify 3 heavy sulfide type, 3 heavy alumina type, 3 heavy silica

type, 4 heavy oxide type or better. JK (Jernkontoret) Chart E45 (ASTM) Plate 1.

Reduction Ratio of AISI 4145H mod forged parts

Must be pressed from 35-inch minimum ingot size and must be press forged (not hammer forged). Forgings must have a minimum reduction ratio of 5:1.

Grain Size of AISI 4145H mod forged bars

Grain size shall be “ASTM 5” or finer as determined by ASTM E112.

Heat treatment of AISI 4145 forged parts

Forgings must be normalized, quenched and tempered.

Preliminary heat treatment of AISI 4145H mod forged bars

Forging must be normalized and tempered to 300 max BHN before rough machining.

Final heat treatment of AISI 4145H forged bars

Forging must be quenched and tempered. Rough machine per supplied process drawings if specified on purchase order

Mechanical Testing Parameters and Frequencies of finished AISI 4145 forged parts

Test sections must not be heat treated separately from product. (12 Inch long one test coupon required per each heat lot). Any single mechanical property test value (Not Average) must meet the above requirements.

Tensile specimens longitudinal; 2" below or mid radius, whichever is closest to the

surface; determined on the basis of one test per ten bodies per heat per heat treat lot.

Impact specimens longitudinal and radially notched; 2" below or mid radius, whichever is

closest to the surface; determined on the basis of one test per ten bodies per heat per heat treat lot. BHN hardness 2" below or mid radius, whichever is closest to the surface; determined on the basis of one test per ten bodies per heat per heat treat lot.

Non-Destructive Examination of AISI 4145H forged parts

Heat treated material shall be ultrasonically inspected per ASTM A388.

The acceptance criteria are ASTM A388, S1. Straight beam only for solid material. Straight beam and angle beam for hollow material.

Dimension/Straightness of finished AISI 4145H Mod forged bars

Straightness: 1/8 inch deviation from straight line in 5-feet.

Surface condition: The typical external surface finish shall be rough turned by the vendor.

Surface imperfections are acceptable if they do not exceed 0.150" maximum depths.

Markings of every pieces of AISI 4145 forged hollow bars

Supplier to hard stencil each body with:

Heat Number

Bar Number

Ingot location, whenever possible and mill practice permit

PO Number

Certification/Documentation of finished AISI 4145H mod forged parts

The supplier shall furnish a certified test report with all requirements per the specification

which includes but is not limited to:

The original mill certificate from the producing mill (melting, grain size,

cleanliness)

Heat Treatment

Heat Number

Lot Number

Chemical composition

Body to furnace lot/load relationship

Mechanical properties

Hardness of each body

Ultrasonic examination results

Welcome your inquiry of AISI 4145H MOD forged parts