Description

Jiangsu Liangyi is professional manufacturer of Inconel X-750,Inconel X750,UNS N07750,,Alloy X-750,Inconel ALloy X-750 open die forging parts and seamless rolled steel forged rings from china

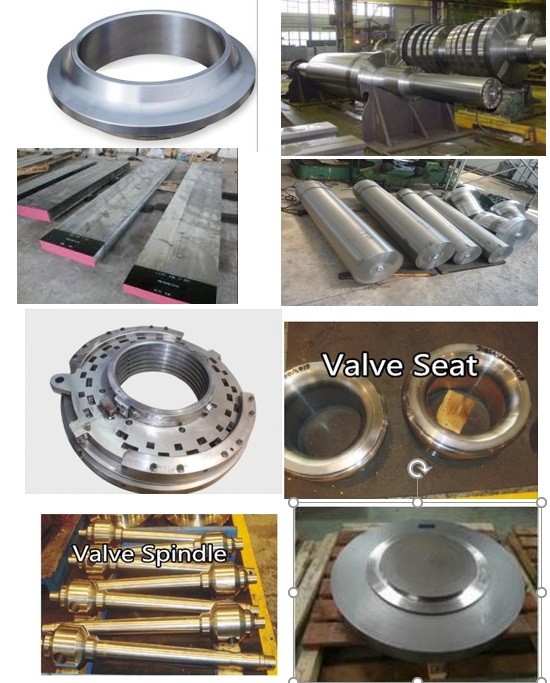

Following is the shape of Inconel X-750,Inconel X750,Inconel ALloy X-750, Alloy X-750,UNS N07750 forging steel material that we could do is:Inconel X-750 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Inconel ALloy X-750 Forged forging steel rings seamless rolled rings,Alloy X-750 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,UNS N07750 Forged Forging Steel Discs Disks Blocks plates,Inconel X-750 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Inconel X750 is a precipitation-hardenable nickel-chromium alloy used for its corrosion and oxidation resistance and high strength at temperatures to 1300°F. Although much of the effect of precipitation hardening is lost with increasing temperature over 1300°F, heat-treated material has useful strength up to 1800°F. Alloy X-750 also has excellent properties down to cryogenic temperatures.

Melting way of inconel x-750 forged bars is as follows:

Alloy shall be multiple melted using consumable electrode practice in the remelt cycle or shall be induction melted under vacuum.If consumable electrode remelting is not performed in vacuum electrodes which have been produced by vacuum induction melting shall be used for remelting

FOllowing is chemical compostion of Inconel ALloy X-750 forged steel rings

|

TABLE Element Carbon Manganese Silicor Phosphorus |

1 -Composition | ||||||||||||||||||||

|

min = |

max 0.08 0.35 0.35 0.015 |

||||||||||||||||||||

| Sulfur | 0.010 | ||||||||||||||||||||

| Chromium | 14.00 | 17.00 | |||||||||||||||||||

| Nickel | 70.00 | ||||||||||||||||||||

| Columbium | 0.70 | 1.20 | |||||||||||||||||||

| Titanium | 2.25 | 2.75 | |||||||||||||||||||

| Aluminum | 0.40 | 1.00 | |||||||||||||||||||

| Iron | 5.00 | 9.00 | |||||||||||||||||||

| Cobalt | -= | 1.00 | |||||||||||||||||||

| Tantalum (3.1.1) | =* | 0.05 | |||||||||||||||||||

| Copper | 0.50 | ||||||||||||||||||||

Inconel x750 forged bars shall be solution heat treated by heating to 1800 F±25 (982 °C±14),holding at heat for a time commensurate with cross-sectional thickness,andcooling at a rate equivalent to an air cool or faster.

precipitation Heat Treatment if inconel x750 forged round bars is :The product shall have the following properties after being precipitation heat treated by heating to 1350°F±15(732 ℃±8),holding at heat for 8 hours±0.25,cooling at a rate of 100 F±15(56 C±8)degrees per hour to 1150 F±15 (621℃±8),holding at 1150 F±15(621 ℃±8)for 8 hours±0.25,and air cooling.Instead of the 100 F(56 C)degrees per hour cooling rate to 1150 °F±15(621 ℃±8),product may be furnace cooled at any rate provided the time at 1150 °F±15(621 ℃±8)is adjusted to give a total precipitation heat treatment time of 18 hours.

FOllowing is two mechanical property of inconel x750 forged rings

| TABLE 1 -Minimum Tensile Properties,Sl Units | |||||||||||||||||||||

| Tensile | Yield Strength | Elongation | Reduction | ||||||||||||||||||

| Specimen | Strength | at 0.2%Ofset | in 4D | of Area | |||||||||||||||||

| Orientation | MPa | MPa | % | % | |||||||||||||||||

| Longitudinal | 1172 | 793 | 18 | 18 | |||||||||||||||||

| Transverse | 1138 | 758 | 15 | 15 | |||||||||||||||||

| TABLE 1 -Minimum Tensile Properties,Inch/Pound Units | |||||||||||||||||||||

| Tensile | Yield Strength | Elongation | Reduction | ||||||||||||||||||

| Specimen | Strength | at 0.2%Offset | in 4D | of Area | |||||||||||||||||

| Orientation | ksi | ksi | % | % | |||||||||||||||||

| Longitudinal | 170 | 115 | 15 | 15 | |||||||||||||||||

| Transverse | 160 | 105 | 12 | 12 | |||||||||||||||||

Longitudinal tensile property requirements apply to specimens taken with the axis approximately parallel to the grain flow,to specimens taken in the radial direction and in the tangential direction at the rim of disc forgings,and tospecimens taken in the circumferential direction from flash welded rings.All other specimens shall be considered to be in the transverse direction.

Transverse tensile property requirements apply only to product from which tensile specimens not less than 2.50 inches (63.5 mm)long can be obtained.

Tensile tests in the longitudinal direction are not required from product tested in the transverse direction.

Hardness:Shall be 302 to 401 HB,or equivalent,determined in accordance with ASTM E10.Product shall not be rejected on the basis of hardness if the tensile properties,determined on specimens taken from the same sample as that with nonconforming hardness or from another sample with similar nonconforming hardness,are acceptable.

Grain flow of inconel x750 forged parts,except in areas which contain flash-line end grain,shall follow the general contour of the forgings showing no evidence of re-entrant grain flow.

FOllowing is inspection standard of inconel x750 forged parts:

ASTM E 8 Tension Testing of Metallic Materials

ASTM E 8M Tension Testing of Metallic Materials (Metric)

ASTM E 10 Brinell Hardness of Metallic Materials

ASTM E 354 Chemical Analysis of High-Temperature,Electrical,Magnetic,and Other Similar Iron,Nickel,and Cobalt Alloys

Following is forging products of Inconel X-750,Inconel X750,Inconel ALloy X-750, Alloy X-750,UNS N07750 material that is used in following industry

Inconel ALloy X-750 forging Forged Drilling Pipes Tubes Drill Rods drill Drilling collar

Alloy X-750 Forged Forging Turbine and Compressor Labyrinth Shaft Seals

Alloy X-750 Forged Forging drilling tools,risers,connectors,flexible joint ,seals,flanges gasket

Inconel X-750 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

ALloy X-750 Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

Inconel X-750 forged steel Mechanical Seal Discs

Inconel Alloy X-750 Forged Forging Steel Butterfly Valve Main Shafts Spindles

Inconel X-750 Forged Forging Gas Air Compressor Rotor

Inconel Alloy X-750 Forged Forging Steels Christmas Trees wellhead Spool Body Bodies cylinder

Alloy X-750 Forged Forging venturi cone meter Body Bodies Blocks

UNS N07750 Forged Forging Steel gate valves Body Bodies bespoke flat bars

Inconel X-750 forged steel Flowseal cryogenic High Performance BV Butterfly Valves HPBV shaft

Inconel X-750 forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

Inconel Alloy X-750 Forged Forging Steel double studded adapter flange

Inconel Alloy X-750 Forged Forging Steel integral Mud Flange Flanged outlet Studded crosses

UNS N07750 Forged Forging Steel Casing Heads,Tubing Heads,Casing Hangers,Tubing Hangers,Tubing Spools,Casing Spools,Spacer Spools

Inconel Alloy X-750 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

Inconel Alloy X-750 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

Inconel Alloy X-750 Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

Inconel Alloy X-750 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

Alloy X-750 Forged Forging forge Steel transition Cone

UNS N07750 Forged Forging Steel Pressure Vessel Reactor Nozzles

Alloy X-750 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

Alloy X-750 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs,turbine wheel discs

Inconel Alloy X-750 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

Inconel Alloy X-750 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

Inconel Alloy X-750 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

Inconel X-750 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

Inconel X-750 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

UNS N07750 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

Inconel X-750 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

Inconel X-750 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

Welcome your inquiry of Inconel X-750,Inconel ALloy X-750, Alloy X-750,UNS N07750) forging forged steel parts