Description

Jiangsu Liangyi is professional manufacturer of Haynes Alloy 188, Haynes 188, Alloy 188,UNS R30188 open die forging parts and seamless rolled steel forged rings from china

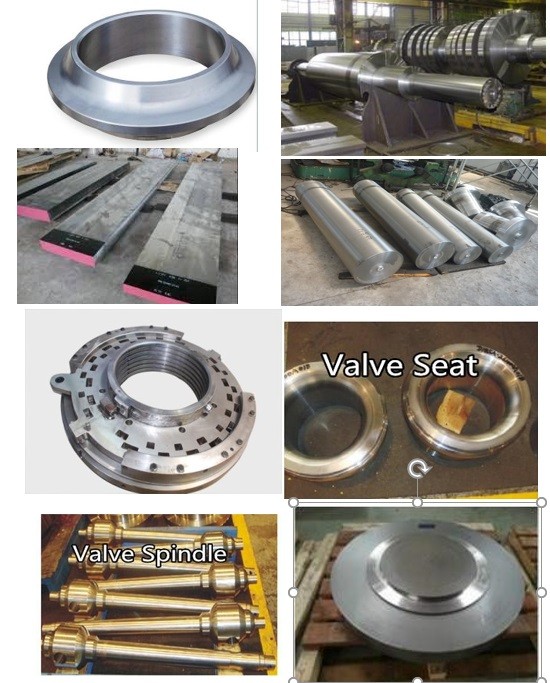

Following is the shape of Haynes Alloy 188, Haynes 188, Alloy 188,UNS R30188 ,Haynes188 forging steel material that we could do is:Haynes 188 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Haynes Alloy 188 Forged forging steel rings seamless rolled rings,Haynes 188 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,UNS R30188 Forged Forging Steel Discs Disks Blocks plates,Alloy 188 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of Haynes Alloy 188, Haynes 188, Alloy 188,UNS R30188 ,Haynes188 material that is used in following industry

Haynes Alloy 188 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

Haynes 188 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

Alloy 188 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

UNS R30188 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

Haynes 188 Forged Forging Rolled Gas Steam Turbine Inner Outer Heat Shields

Alloy 188 Forged Forging Rolled Steel Gas Steam Turbine shrouds

Haynes 188 forging forged steel tube sheets, baffle plates, nozzles,flanges for heat exchanger

Haynes 188 material for furnace retorts, chains and fixtures, burner flame shrouds, recuperator internals, dampers, nitriding furnace internals, heat-treating baskets, grates, trays, sparger tubes, thermocouple protection tubes, cyclone internals

Alloy 188 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

Haynes 188 forged forging hot working dies,tooling, die blocks,mould, mold.

Haynes 188 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

Haynes 188 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

Alloy 188 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

Alloy 188 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

Haynes Alloy 188 is a Cobalt-Nickel-Chromium-Tungsten Alloy that combines excellent high temperature strength with very good resistance to oxidizing environments up to 2000°F (1095°C). for prolonged exposures, and excellent resistance to sulfate deposit hot corrosion. It is readily fabricated and formed by conventional techniques, and has been used for cast component. Other attractive features include excellent resistance to molten chloride salts, and good resistance to gaseous sulfidation.

Haynes 188 is a solid solution-strengthened material which combines excellent high temperature strength. It is particularly effective for very long-term applications at temperatures of 1200°F (650°C) or more. It is stronger than nickel-base solid-solutionstrengthened alloys, and far stronger than simple nickel-chromium or iron-nickel-chromium heat-resistant alloys.

Forgings Haynes 188 maeterial shall be manufactured from steel produced by vacuum induction melting 1 electro-slag re-melting {VIM/ESR) or by vacuum induction melting 1 vacuum are re-melting (VIM/VAR) process.

The hot working shall be done in such a way that a uniform fine grained microstructure is achieved.

The Haynes 188 forged material shall undergo the following heat treatment:

Haynes 188 are furnished in the solution heat-treated condition unless otherwise specified. Alloy 188 is normally solution heat-treated at 2150°F +/-25°F (1177°C +/-14°C) and rapid air cooled or water quenched. Bright annealed products are cooled in hydrogen.

FOllowing is production standard of Haynes 188 forging material

AMS 5772 ,GE B50TF74

Chemical composition of Haynes Alloy 188, Haynes 188, Alloy 188,UNS R30188 ,Haynes188 forging turbine parts is as

Cobalt.........................................................................Balance

Carbon........................................................................0.05-0.15

Manganese.................................................................1.25 max.

Silicon.........................................................................0.20-0.50

Chromium...................................................................20.0-24.0

Nickel..........................................................................20.0-24.0

Tungsten.....................................................................13.0-16.0

Lanthanum..................................................................0.02-0.12

Boron........................................................................0.015 max.

Iron...............................................................................3.0 max.

Following is heat treatment methods of Haynes 188 forging rings

furnished in the solution heat treated condition, unless otherwise specified. The alloy is solution heat-treated in the range of 2150 to 2275°F (1177 to 1246°C) and rapidly cooled or water-quenched for optimum properties.

mechanical property of for Haynes Alloy 188, Haynes 188, Alloy 188,UNS R30188 ,Haynes188 forged round bars is as follow

Ultimate Tensile Strength: 125 KSI min (862 MPa min)

Yield Strength (0.2% offset): 55 KSI min (379 MPa min)

Elongation: 45% min

.

We have following Forging Equipments of make forging of Haynes 188 forging material, 4500t &850000t Hydraulic forging equipments; 50t&15t Manipulators; 2t&1t&450kg air hammer; 5t electro hydraulic hammer etc.

We have Heat treatment Equipments of make forged of Alloy 188 forgedc parts φ2*12m pit furnace; φ8*3*3m table resistor furnace; 1.5*0.8*1.5m box resistor furnace; 8*3*3m gas furnace; 6*3*2m gas furnace; 7.5*4*2.5 gas furnace;16*2.5*2.5 gas furnace etc.

Also we have following Machining Equipments of maching Haynes Alloy 188 forging parts, ; including φ2*12m heavy sleeper; φ5m vertical lathe; floor type boring and milling machine; CNC miller ;φ1.6*16m heavy sleeper; single-arm planer; boring and milling machine etc.

After finished all our Haynes Alloy 188 forging material will be done in following test

Tensile testing

Charpy Testing (-320°F to +350°F)

Hardness testing

Macro-etching

Non-Destructive Test Capabilities to Military and Commercial Standards (ASNT)

Level III / Test Examiner

Level II inspectors qualified to perform

Ultrasonic testing

Liquid penetrant inspection

Magnetic particle inspection

Dimensional/visual inspection

Metrology laboratory (dimensional)

Pyrometry laboratory (temperature)

Welcome your inquiry of Haynes Alloy 188, Haynes 188, Alloy 188,UNS R30188 ,Haynes188 forging parts

Following is the shape of Haynes Alloy 188, Haynes 188, Alloy 188,UNS R30188 ,Haynes188 forging steel material that we could do is:Haynes 188 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Haynes Alloy 188 Forged forging steel rings seamless rolled rings,Haynes 188 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,UNS R30188 Forged Forging Steel Discs Disks Blocks plates,Alloy 188 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of Haynes Alloy 188, Haynes 188, Alloy 188,UNS R30188 ,Haynes188 material that is used in following industry

Haynes Alloy 188 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

Haynes 188 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

Alloy 188 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

UNS R30188 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

Haynes 188 Forged Forging Rolled Gas Steam Turbine Inner Outer Heat Shields

Alloy 188 Forged Forging Rolled Steel Gas Steam Turbine shrouds

Haynes 188 forging forged steel tube sheets, baffle plates, nozzles,flanges for heat exchanger

Haynes 188 material for furnace retorts, chains and fixtures, burner flame shrouds, recuperator internals, dampers, nitriding furnace internals, heat-treating baskets, grates, trays, sparger tubes, thermocouple protection tubes, cyclone internals

Alloy 188 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

Haynes 188 forged forging hot working dies,tooling, die blocks,mould, mold.

Haynes 188 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

Haynes 188 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

Alloy 188 Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

Alloy 188 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

Haynes Alloy 188 is a Cobalt-Nickel-Chromium-Tungsten Alloy that combines excellent high temperature strength with very good resistance to oxidizing environments up to 2000°F (1095°C). for prolonged exposures, and excellent resistance to sulfate deposit hot corrosion. It is readily fabricated and formed by conventional techniques, and has been used for cast component. Other attractive features include excellent resistance to molten chloride salts, and good resistance to gaseous sulfidation.

Haynes 188 is a solid solution-strengthened material which combines excellent high temperature strength. It is particularly effective for very long-term applications at temperatures of 1200°F (650°C) or more. It is stronger than nickel-base solid-solutionstrengthened alloys, and far stronger than simple nickel-chromium or iron-nickel-chromium heat-resistant alloys.

Forgings Haynes 188 maeterial shall be manufactured from steel produced by vacuum induction melting 1 electro-slag re-melting {VIM/ESR) or by vacuum induction melting 1 vacuum are re-melting (VIM/VAR) process.

The hot working shall be done in such a way that a uniform fine grained microstructure is achieved.

The Haynes 188 forged material shall undergo the following heat treatment:

Haynes 188 are furnished in the solution heat-treated condition unless otherwise specified. Alloy 188 is normally solution heat-treated at 2150°F +/-25°F (1177°C +/-14°C) and rapid air cooled or water quenched. Bright annealed products are cooled in hydrogen.

FOllowing is production standard of Haynes 188 forging material

AMS 5772 ,GE B50TF74

Chemical composition of Haynes Alloy 188, Haynes 188, Alloy 188,UNS R30188 ,Haynes188 forging turbine parts is as

Cobalt.........................................................................Balance

Carbon........................................................................0.05-0.15

Manganese.................................................................1.25 max.

Silicon.........................................................................0.20-0.50

Chromium...................................................................20.0-24.0

Nickel..........................................................................20.0-24.0

Tungsten.....................................................................13.0-16.0

Lanthanum..................................................................0.02-0.12

Boron........................................................................0.015 max.

Iron...............................................................................3.0 max.

Following is heat treatment methods of Haynes 188 forging rings

furnished in the solution heat treated condition, unless otherwise specified. The alloy is solution heat-treated in the range of 2150 to 2275°F (1177 to 1246°C) and rapidly cooled or water-quenched for optimum properties.

mechanical property of for Haynes Alloy 188, Haynes 188, Alloy 188,UNS R30188 ,Haynes188 forged round bars is as follow

Ultimate Tensile Strength: 125 KSI min (862 MPa min)

Yield Strength (0.2% offset): 55 KSI min (379 MPa min)

Elongation: 45% min

.

We have following Forging Equipments of make forging of Haynes 188 forging material, 4500t &850000t Hydraulic forging equipments; 50t&15t Manipulators; 2t&1t&450kg air hammer; 5t electro hydraulic hammer etc.

We have Heat treatment Equipments of make forged of Alloy 188 forgedc parts φ2*12m pit furnace; φ8*3*3m table resistor furnace; 1.5*0.8*1.5m box resistor furnace; 8*3*3m gas furnace; 6*3*2m gas furnace; 7.5*4*2.5 gas furnace;16*2.5*2.5 gas furnace etc.

Also we have following Machining Equipments of maching Haynes Alloy 188 forging parts, ; including φ2*12m heavy sleeper; φ5m vertical lathe; floor type boring and milling machine; CNC miller ;φ1.6*16m heavy sleeper; single-arm planer; boring and milling machine etc.

After finished all our Haynes Alloy 188 forging material will be done in following test

Tensile testing

Charpy Testing (-320°F to +350°F)

Hardness testing

Macro-etching

Non-Destructive Test Capabilities to Military and Commercial Standards (ASNT)

Level III / Test Examiner

Level II inspectors qualified to perform

Ultrasonic testing

Liquid penetrant inspection

Magnetic particle inspection

Dimensional/visual inspection

Metrology laboratory (dimensional)

Pyrometry laboratory (temperature)

Welcome your inquiry of Haynes Alloy 188, Haynes 188, Alloy 188,UNS R30188 ,Haynes188 forging parts