Description

Jiangsu Liangyi professional manufacturer of AMS 5763,AMS 5773 open die forging parts and seamless rolled steel forged rings from china

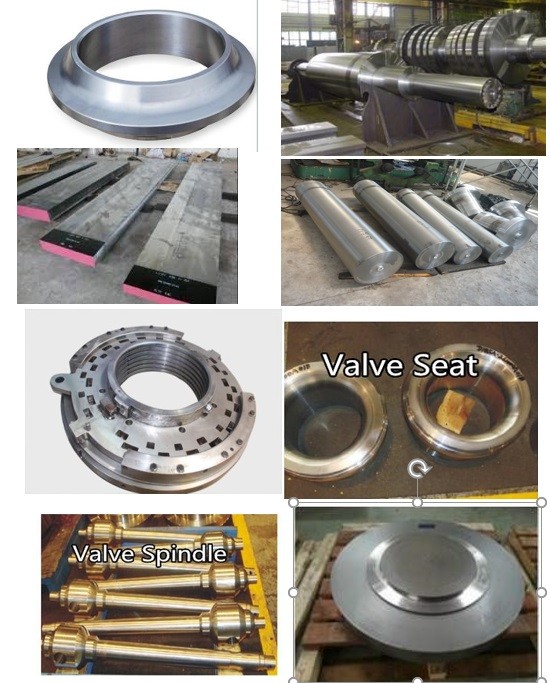

Following is the shape of AMS 5763,AMS 5773 forging steel material that we could do is:1.4594 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,AMS 5763 Forged forging steel rings seamless rolled rings,AMS 5773 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,AMS 5773 Forged Forging Steel Discs Disks Blocks plates,AMS 5763 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of AMS 5763,AMS 5773 material that is used in following industry

AMS 5763 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

AMS 5773 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

AMS 5763 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

AMS 5773 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

AMS 5763 forged forging steel pump case, pump impeller, pump wear rings, pump shafts

AMS 5773 forged forging steel valve bonnet, valve body, valve closure, valve stems, valve seat rings, valve core, valve discs

AMS 5763 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

The melting methods of AMS 5763,AMS 5773 forged steam turbine blade steel is as follows: The Steel shall be made using the basic electric furnace process with either the Electro-Slag Re-Melt (ESR) or Vacuum- Arc-Re-Melt(VAR) process. Alloy melting requirements shall be compatible with AMS5773E.

AMS 5763,AMS 5773 is is a high-temperature steel alloy with exceptional corrosion resistance and excellent mechanical properties. This alloy is also known as precipitation-hardening steel, which means that it undergoes a process of heat treatment and cooling to enhance its strength and durability over long periods. With its ability to withstand high temperatures, AMS 5763 is commonly used in aircraft engines, gas turbines, and other critical applications where reliability and performance are crucial. As an expert in the field, AMS5763 is as one of the most reliable and effective steel alloys available for high-temperature applications. pump shafts, impellers, fasteners, fans, valves, hydraulic equipment used in oil and gas industries,pertrochemical, marine and nuclear engineering . aircraft components such as steam turbine blades

FOllowing is chemical compostion of AMS 5763,AMS 5773 forged steel flat bars

Carbon (Maximum)0.05

Phosphorus (Maximum)0.03

Silicon (Maximum)1

Nickel (Nominal)5.00-7.00

Manganese (Maximum)1

Sulfur (Maximum)0.03

Chromium (Nominal)14.00-16.00

Molybdenum (Nominal)0.50-1.00

Iron (Nominal)Balance

Copper (Nominal)1.25-1.75

Columbium/Niobium8 X C Minimum

Mechanical properties of steel AMS 5763,AMS 5773 forged steel bars

H900 H950 H1000 H1050 H1100 H1150 heat treatment condition

0.2% Proof Strength

ksi 170 160 150 135 105 75

MPa 1172 1103 1034 931 724 517

UTS

ksi 740 170 160 145 130 125

MPa 1241 1172 1103 1000 896 862

Elongation %

long 10 10 12 12 16 18

trans 6 7 8 9 11 12

Reduction of area

Long 40 40 45 45 50 55

Max 20 22 27 30 30 35

Hardness HB Min 363 341 331 321 285 262

Following is production process of AMS 5763,AMS 5773 forging steel parts

Forging process flow quality control: Raw material steel ingot into warehouse(test the chemical content) → Cutting→ Forged process→ Post forging heat treatment(N+T)→ UT→ Rough Machining→ UT → QT→ Inspection(UT, mechanical properties, hardness, grain size)→ Grooving→ Stress relieve Tempering → Machining holding postion for rotor when HST→ HST→ Inspection (dimension)→ Packing and Marking(steel stamp, mark)→ Storage Shipment

For our finished production of AMS 5763,AMS 5773 forged steel bars should have following inspection report

Identification number, material number and designation, order number, drawing number,

Specification Number;

- Heat number, heat chemical analysis, melting method and product chemical analysis;

- Certificate of heat treatment including method of cooling, actual part temperature, holding

time, cooling condition and all re-heat-treatments by complete graphic temperature time;

- Nondestructive testing records,

- Results of all Mechanical Tests,

-Results of residual stress measurements (for process qualification),

- All probable deviation reports,

- Certification of NDT inspector,

- Dimensional and visual inspection report,

- Cleaning Verified