Description

Jiangsu Liangyi is professional manufacturer of 2.4669,NiCr15Fe7TiAl open die forging parts and seamless rolled steel forged rings from china

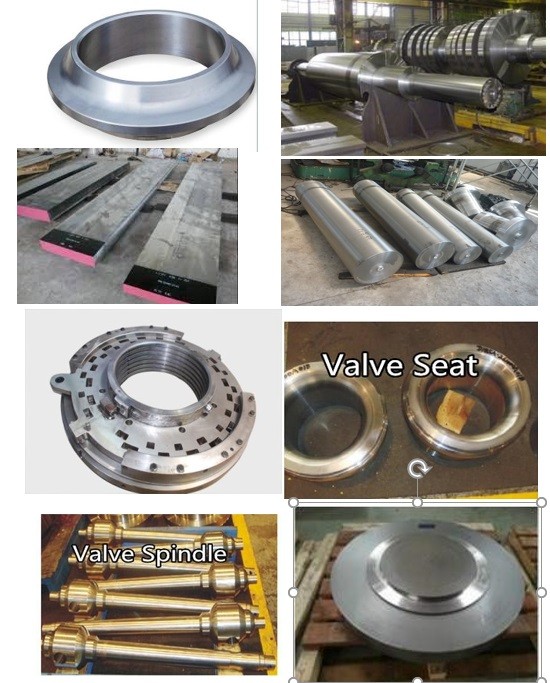

Following is the shape of 2.4669,NiCr15Fe7TiAl forging steel material that we could do is:2.4669 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,2.4669 Forged forging steel rings seamless rolled rings,2.4669 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,NiCr15Fe7TiAl Forged Forging Steel Discs Disks Blocks plates,NiCr15Fe7TiAl Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

2.4669 is one of the most widely used materials among nickel-based super alloys. It is a material that can withstand even highly corrosive environments, can be hardened by aging and is basically formed by the combination of nickel and chromium elements.

2.4669 is widely used ine gas turbine components (both aero and industrial turbines), high temperature fasteners, springs and rocket engines. After slightly different heat treatment, 2.4669 is also used for nuclear reactor components, typically pressurised water reactors (PWR's) and boiling water reactors (BWR's). It can also be used for applications in cryogenic temperatures.

The production standard of 2.4669,NiCr15Fe7TiAl forging parts is as following

EN 10269: 1999 Steels and nickel alloys for fasteners with specified elevated and/or low temperature properties

EN 10302: 2008 Creep resisting steels, nickel and cobalt alloys

Chemical composition of 2.4669,NiCr15Fe7TiAl forging turbine parts is as

Nickel (Ni) 65.9 to 77.7

Chromium (Cr) 14 to 17

Iron (Fe) 5.0 to 9.0

Titanium (Ti) 2.3 to 2.8

Niobium (Nb) 0.7 to 1.2

Aluminum (Al) 0.4 to 1.0

Manganese (Mn) 0 to 1.0

Cobalt (Co) 0 to 1.0

Silicon (Si) 0 to 0.5

Copper (Cu) 0 to 0.5

Carbon (C) 0 to 0.080

Phosphorus (P) 0 to 0.020

Sulfur (S) 0 to 0.015

mechanical property of for 2.4669,NiCr15Fe7TiAl forged round bars is as follow

Rm - Tensile strength (MPa) (+P980) 980

Rm - Tensile strength (MPa) (+P1170) 1170

Rp0.2 0.2% proof strength (MPa) (+P980) 630

Rp0.2 0.2% proof strength (MPa) (+P1170) 790

KV - Impact energy (J) longitud., (+AT) +20°22 -196° 20

An inspection certificate 3.1 according EN 10204 of our 2.4669 forged bars should have following

purchase order, item, serial n°, drawing number and number of the technical purchasing

specification

material designation

heat n° and heat analysis

method of melting

manufacturing procedure

heat treatment: cooling method (rates and mean of cooling) and measured temperatures.

All heat treatment conditions have to be quoted in a graphic temperature against time

sequence (including all re-heat-treatments). Reports including only average holding

temperatures and times are acceptable.

results of metallographic analysis

mechanical tests certificates, including single values

results and recording of NDT. A dedicated certificate for each performed NDT is required

dimensional report (tabular or graphically) complete of a certificate of compliance

Each 2.4669 forging parts shall be plainly stamped as per clients requirement on one side of the rim,near the periphery, with the following:

a.Purchaser Agreement Number.

b.PDS-Specification and Revision Number.

c.Drawing Number,including Item Number and Issue Number.

d.Forging Number.

e.Test Number.

Forgings shall not be shipped unless stamped by the Purchaser's representative.

Marking methodshall follow the requirements of applicable drawing(s)listed on the Purchase Order.

Following is forging products of 2.4669, NiCr15Fe7TiAl material that is used in following industry

2.4669 forging Forged Drilling Pipes Tubes Drill Rods drill Drilling collar

2.4669 Forged Forging Turbine and Compressor Labyrinth Shaft Seals

2.4669 Forged Forging drilling tools,risers,connectors,flexible joint ,seals,flanges gasket

2.4669 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

2.4669 Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

2.4669 forged steel Mechanical Seal Discs

2.4669 Forged Forging Steel Butterfly Valve Main Shafts Spindles

2.4669 Forged Forging Swept branches outlets steel fittings swept saddles

2.4669 Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

2.4669 Forged Forging Steels Christmas Trees wellhead Spool Body Bodies cylinder

2.4669 Forged Forging venturi cone meter Body Bodies Blocks

NiCr15Fe7TiAl Forged Forging Steel gate valves Body Bodies bespoke flat bars

2.4669 forged steel Flowseal cryogenic High Performance BV Butterfly Valves HPBV shaft

2.4669 forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

2.4669 Forged Forging Steel double studded adapter flange

2.4669 Forged Forging Steel integral Mud Flange Flanged outlet Studded crosses

NiCr15Fe7TiAl Forged Forging Steel Casing Heads,Tubing Heads,Casing Hangers,Tubing Hangers,Tubing Spools,Casing Spools,Spacer Spools

2.4669 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

2.4669 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

2.4669 Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

2.4669 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

2.4669 Forged Forging forge Steel transition Cone

NiCr15Fe7TiAl Forged Forging Steel Pressure Vessel Reactor Nozzles

2.4669 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

2.4669 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs,turbine wheel discs

2.4669 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

2.4669 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

2.4669 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

2.4669 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

2.4669 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

NiCr15Fe7TiAl Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

2.4669 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

2.4669 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

Welcome your inquiry of 2.4669,NiCr15Fe7TiAl forging parts

Following is the shape of 2.4669,NiCr15Fe7TiAl forging steel material that we could do is:2.4669 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,2.4669 Forged forging steel rings seamless rolled rings,2.4669 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,NiCr15Fe7TiAl Forged Forging Steel Discs Disks Blocks plates,NiCr15Fe7TiAl Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

2.4669 is one of the most widely used materials among nickel-based super alloys. It is a material that can withstand even highly corrosive environments, can be hardened by aging and is basically formed by the combination of nickel and chromium elements.

2.4669 is widely used ine gas turbine components (both aero and industrial turbines), high temperature fasteners, springs and rocket engines. After slightly different heat treatment, 2.4669 is also used for nuclear reactor components, typically pressurised water reactors (PWR's) and boiling water reactors (BWR's). It can also be used for applications in cryogenic temperatures.

The production standard of 2.4669,NiCr15Fe7TiAl forging parts is as following

EN 10269: 1999 Steels and nickel alloys for fasteners with specified elevated and/or low temperature properties

EN 10302: 2008 Creep resisting steels, nickel and cobalt alloys

Chemical composition of 2.4669,NiCr15Fe7TiAl forging turbine parts is as

Nickel (Ni) 65.9 to 77.7

Chromium (Cr) 14 to 17

Iron (Fe) 5.0 to 9.0

Titanium (Ti) 2.3 to 2.8

Niobium (Nb) 0.7 to 1.2

Aluminum (Al) 0.4 to 1.0

Manganese (Mn) 0 to 1.0

Cobalt (Co) 0 to 1.0

Silicon (Si) 0 to 0.5

Copper (Cu) 0 to 0.5

Carbon (C) 0 to 0.080

Phosphorus (P) 0 to 0.020

Sulfur (S) 0 to 0.015

mechanical property of for 2.4669,NiCr15Fe7TiAl forged round bars is as follow

Rm - Tensile strength (MPa) (+P980) 980

Rm - Tensile strength (MPa) (+P1170) 1170

Rp0.2 0.2% proof strength (MPa) (+P980) 630

Rp0.2 0.2% proof strength (MPa) (+P1170) 790

KV - Impact energy (J) longitud., (+AT) +20°22 -196° 20

An inspection certificate 3.1 according EN 10204 of our 2.4669 forged bars should have following

purchase order, item, serial n°, drawing number and number of the technical purchasing

specification

material designation

heat n° and heat analysis

method of melting

manufacturing procedure

heat treatment: cooling method (rates and mean of cooling) and measured temperatures.

All heat treatment conditions have to be quoted in a graphic temperature against time

sequence (including all re-heat-treatments). Reports including only average holding

temperatures and times are acceptable.

results of metallographic analysis

mechanical tests certificates, including single values

results and recording of NDT. A dedicated certificate for each performed NDT is required

dimensional report (tabular or graphically) complete of a certificate of compliance

Each 2.4669 forging parts shall be plainly stamped as per clients requirement on one side of the rim,near the periphery, with the following:

a.Purchaser Agreement Number.

b.PDS-Specification and Revision Number.

c.Drawing Number,including Item Number and Issue Number.

d.Forging Number.

e.Test Number.

Forgings shall not be shipped unless stamped by the Purchaser's representative.

Marking methodshall follow the requirements of applicable drawing(s)listed on the Purchase Order.

Following is forging products of 2.4669, NiCr15Fe7TiAl material that is used in following industry

2.4669 forging Forged Drilling Pipes Tubes Drill Rods drill Drilling collar

2.4669 Forged Forging Turbine and Compressor Labyrinth Shaft Seals

2.4669 Forged Forging drilling tools,risers,connectors,flexible joint ,seals,flanges gasket

2.4669 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate valve

2.4669 Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

2.4669 forged steel Mechanical Seal Discs

2.4669 Forged Forging Steel Butterfly Valve Main Shafts Spindles

2.4669 Forged Forging Swept branches outlets steel fittings swept saddles

2.4669 Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

2.4669 Forged Forging Steels Christmas Trees wellhead Spool Body Bodies cylinder

2.4669 Forged Forging venturi cone meter Body Bodies Blocks

NiCr15Fe7TiAl Forged Forging Steel gate valves Body Bodies bespoke flat bars

2.4669 forged steel Flowseal cryogenic High Performance BV Butterfly Valves HPBV shaft

2.4669 forging steel Oil measurement valve Spool Ultrasonic flow meter bodies Body

2.4669 Forged Forging Steel double studded adapter flange

2.4669 Forged Forging Steel integral Mud Flange Flanged outlet Studded crosses

NiCr15Fe7TiAl Forged Forging Steel Casing Heads,Tubing Heads,Casing Hangers,Tubing Hangers,Tubing Spools,Casing Spools,Spacer Spools

2.4669 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

2.4669 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

2.4669 Forged Forging Steel Forged Single Double Bossed boss Blanks FLANGED BOSSES

2.4669 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings,pump case casing.

2.4669 Forged Forging forge Steel transition Cone

NiCr15Fe7TiAl Forged Forging Steel Pressure Vessel Reactor Nozzles

2.4669 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

2.4669 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs,turbine wheel discs

2.4669 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts bolting

2.4669 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

2.4669 Forged Forging Steel Gas Steam turbine diaphragm diapharagm nozzles

2.4669 Forged Forging Gas Turbine LPT 1st & 2st 2nd Stg Stage Turbine Case Casings

2.4669 Forged Forging Steel power plant steam turbine control reheat valve disc Disk

NiCr15Fe7TiAl Forged forging Gas Steam Turbine Valve Spindles/Stems/Rods,

2.4669 Forging Steel Gas Steam Turbine MSV/GV/CV/CRV Valve Seats, Valve Cores, Valve Sleeves Spools,,Main Steam Valve Covers Bonnets Sleeves

2.4669 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets,baffle plates, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

Welcome your inquiry of 2.4669,NiCr15Fe7TiAl forging parts