Description

Jiangsu Liangyi professional manufacturer of X1CrNiMoAl12-9(Z1CNDA12-09,Z 4 CNDAT 13-09,Z4CNDAT13-09,Z1CNDA12.09)open die forging parts and seamless rolled steel forged rings from china

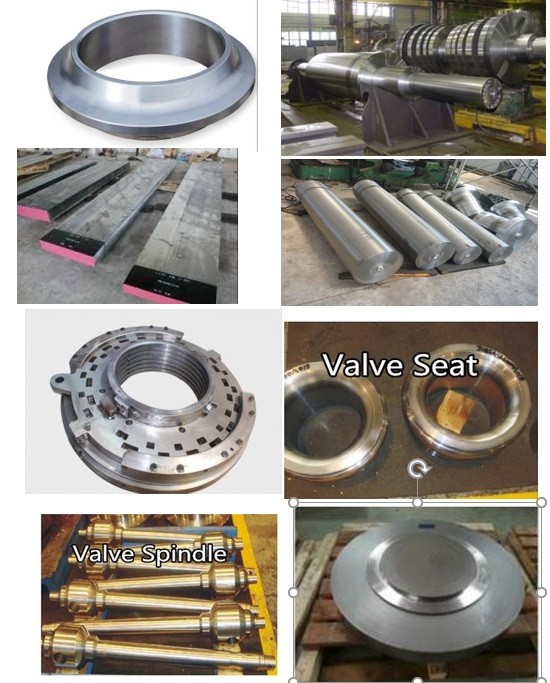

Following is the shape of X1CrNiMoAl12-9(Z1CNDA12-09,Z 4 CNDAT 13-09,Z4CNDAT13-09,Z1CNDA12.09) forging steel material that we could do is:X1CrNiMoAl12-9 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,Z 4 CNDAT 13-09,Forged forging steel rings seamless rolled rings,Z1CNDA12-09 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,Z4CNDAT13-09 Forged Forging Steel Discs Disks Blocks plates,Z1CNDA12.09 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of X1CrNiMoAl12-9(Z1CNDA12-09,Z 4 CNDAT 13-09,Z4CNDAT13-09,Z1CNDA12.09) material that is used in following industry

X1CrNiMoAl12-9 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

Z1CNDA12-09 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

Z1CNDA12.09 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

Z4CNDAT13-09 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

X1CrNiMoAl12-9 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

X1CrNiMoAl12-9 Forged Forging ultra high pressure water jet Waterjet cutting Machine Cutter Hydraulic Cylinder,accumulator attenuator

Z1CNDA12-09 forged steel ultra high pressure water jet Waterjet cutting Machine Cutter intensifier pump Sealing Heads

Z4CNDAT13-09 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate pump

Z1CNDA12.09 Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

Z4CNDAT13-09 Forged Forging Marine Ship Boat Propeller Shafts

X1CrNiMoAl12-9 Forged Forging downhole drilling tool Mud Motor Splined Drive shafts,Down hole Electric electrical submersible pumps ESP motor Splined Shaft

Z1CNDA12-09 Forged Forging Steel integral Mud Flange Flanged outlet Studded crosses

X1CrNiMoAl12-9 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

Z1CNDA12-09 forging injection molding,mould, dies block,tooling

Z1CNDA12.09 Forged Forging turbomachinery turbo centrifugal compressor Impeller,Compressor Shrouded Impellers

Z1CNDA12.09 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings

X1CrNiMoAl12-9(Z1CNDA12-09,Z 4 CNDAT 13-09,Z4CNDAT13-09,Z1CNDA12.09) is a martensitic precipitation/age-hardening stainless steel capable of high strength and hardness along with good levels of resistance to both general corrosion and stress-corrosion cracking. In addition, the alloy exhibits good ductility and toughness in large sections in both the longitudinal and transverse directions. The excellent properties of Z1CNDA12-09 stainless are obtained through close control of chemical composition and microstructure plus specialized melting which reduces impurities and minimizes segregation. Compared to other ferrous-based materials, this alloy offers a high level of useful mechanical properties under severe environmental conditions.

X1CrNiMoAl12-9(Z1CNDA12-09,Z 4 CNDAT 13-09,Z4CNDAT13-09,Z1CNDA12.09) stainless has displayed excellent resistance to oxidation up to approximately 1100°F. Long-term exposure to temperatures between about 600-900°F (288-482°C) can result in reduced toughness in precipitation hardenable stainless steels. The reduction in toughness can be minimized in some cases by using higher aging temperatures. Short exposures to elevated temperatures can be considered, provided the maximum temperature is at least 50°F (28°C) less than the aging temperature.

Our X1CrNiMoAl12-9(Z1CNDA12-09,Z 4 CNDAT 13-09,Z4CNDAT13-09,Z1CNDA12.09) forged steel parts is normal melting by Basic Electric Furnace (EAF, AOD, VOD) or + Electroslag remelting. (ESR) AS PER CLIENTS NEEDS

FOllowing is chemical compostion of X1CrNiMoAl12-9(Z1CNDA12-09,Z 4 CNDAT 13-09,Z4CNDAT13-09,Z1CNDA12.09) forged steel sleeves

C: max. 0,04 %

Cr: 11.5- 13,25 %

Mn: max. 0,2%

Mo: 1.8 - 2,5 %

Ni: 7,5 - 9,5 %

P: max. 0,015 %

S: max. 0,008 %

Si: max. 0,1 %

Ti: max. 0,4 %

Al: 0,6 - 1,4 %

Following of X1CrNiMoAl12-9(Z1CNDA12-09,Z 4 CNDAT 13-09,Z4CNDAT13-09,Z1CNDA12.09) forging parts mechnical property :

Tensile strength .............................. 1010Mpa

Yield strength .................................... ... ... 825Mpa

Elongation ............................................. 17%

Section reduction rate ........................................ 65%

Hardness ................................................ 33HRC

Impact work CvJ ........................... 81 Portrait 54 Landscape

Our X1CrNiMoAl12-9(Z1CNDA12-09,Z 4 CNDAT 13-09,Z4CNDAT13-09,Z1CNDA12.09) forged material is qualified in certificate of ISO 9001,ISO 14001.ISO 50001,ISO 3834-2, ISO 9712,ISO/IEC 17025,NORSOK M122,NORSOK M123

All our X1CrNiMoAl12-9(Z1CNDA12-09,Z 4 CNDAT 13-09,Z4CNDAT13-09,Z1CNDA12.09) forged steel parts can be release in 10204-3.2 certificate by following third party DNV-GL BUREAU VERITAS,LLOYD’S REGISTER,ABS, RINA,TÜV

Welcome your inquiry of X1CrNiMoAl12-9(Z1CNDA12-09,Z 4 CNDAT 13-09,Z4CNDAT13-09,Z1CNDA12.09) forging forged steel parts