Description

Jiangsu Liangyi professional manufacturer of ASTM A565/A565M XM32 XM-32(UNS k64152,UNS S64152, Jethete M152) open die forging parts and seamless rolled steel forged rings from china

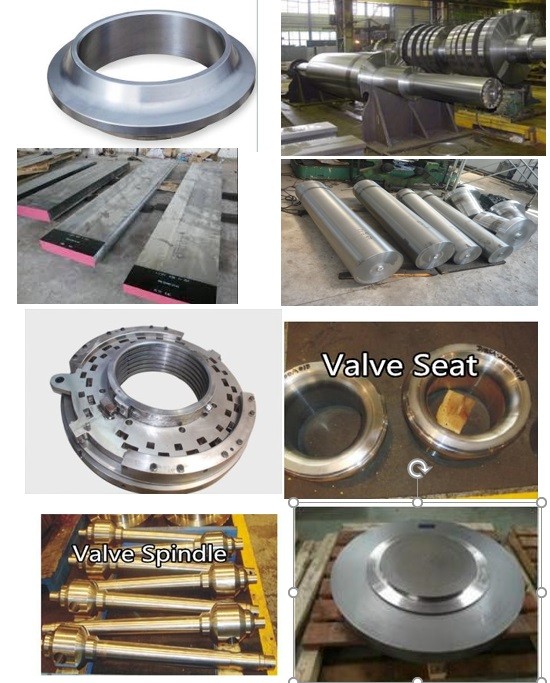

Following is the shape of ASTM A565/A565M XM32 XM-32(UNS k64152,UNS S64152, Jethete M152) Forging steel material that we could do is:ASTM A565/A565M XM32 Forged Steel round bars square bars Flat bars Rectangles Bars Rods, ASTM A565/A565M XM-32 Forged forging steel rings seamless rolled rings, UNS S64152 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars, UNS k64152 Forged Forging Steel Discs Disks Blocks plates, UNS S64152 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings. Jethete M152 Forged Forging Steel Gas Steam Turbine Rotors Shafts Turbine Blades turbine impeller, turbine disks turbine blisks, turbine bolts, Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings turbine bolts

Our ASTM A565/A565M XM32 XM-32(UNS k64152,UNS S64152, Jethete M152) forged steel parts is normal melting by Basic Electric Furnace (EAF, AOD, VOD) or + Electroslag remelting. (ESR) AS PER CLIENTS NEEDS

ASTM A565/A565M XM32 XM-32(UNS k64152,UNS S64152, Jethete M152) is is a nitrogen-bearing, hardenable 12% chromium martensitic stainless steel with high strength at higher temperatures and excellent creep and corrosion resistance. It is supplied as hardened and tempered steel with very good toughness, creep-rupture properties, and temper resistance at temperatures up to 1040° F (560° C).

ASTM A565/A565M XM32 XM-32(UNS k64152,UNS S64152, Jethete M152) is normal used in High heat bolts in aerospace applications, Gas turbine parts. Rings and structural components for land-based turbines, fasteners, drilling equipment, mechanical gears, aircraft landing gear, turbine blades, mechanical parts.

Chemical composition % of steel ASTM A565/A565M XM32 XM-32 forging steel turbine blade steel is as followings

Iron (Fe) 80.6 to 84.7

Chromium (Cr) 11 to 12.5

Nickel (Ni) 2.0 to 3.0

Molybdenum (Mo) 1.5 to 2.0

Manganese (Mn) 0.5 to 0.9

Vanadium (V) 0.25 to 0.4

Silicon (Si) 0 to 0.35

Carbon (C) 0.080 to 0.15

Nitrogen (N) 0.010 to 0.050

Phosphorus (P) 0 to 0.025

Sulfur (S) 0 to 0.025

Mechanical properties of steel Jethete M152 forging steel rings

Tensile strength (MPa) 1000 min

Yield strength (MPa) 795 min

Elongation (%) 15 min

Reduction of area (%) 30 min

Impact CVN Joule 40 min

Brinell Hardness 302~352

We have following forging production equipment for all our UNS S64152 forging steel parts

6 mobile hearth heating furnaces with a loading capacity of 10t up to 80t, equipped with a centralized automatic controlled system of the heating cycles;

a 6.300 tons semiautomatic hydraulic press;

a 3.500 tons semiautomatic hydraulic press;

a 70 tons capacity manipulator;

a 36 tons capacity manipulator;

a 24 tons capacity manipulator;

a 12 tons manipulator on rails.

The capacity of our a wide range of ASTM A565/A565M XM32 forging parts is in different shapes and sizes, weighing up to 35 tons.

We have following heat treatment equipment for all our UNS K64152 forging material

21 gas furnaces with a loading capacity of 20t up to 80t and a max length of 16m;

1 electric furnaces with a max capacity of 20 tons;

2 130 and 200 m3 quenching tanks filled with water;

2 110 and 200 m3 quenching tanks filled with water and a polymer solution.

All furnaces are equipped with an automatic programming system controlled by a centralized computer with a heat treatment cycle recording system.

Quenching tanks are equipped with an automatic cooling system which keeps the liquid within the temperature requested.

We have following inspection equipment to inspect of all our ASTM A565/A565M XM32 XM-32 forging steel gas steam turbine parts

a well equipped chemical lab which carries out test analysis on the steel heats made in the steel mill

a well equipped lab which carries out mechanical tensile & resilience tests as well as creep tests

a metallurgic lab for structural macro-micro and inclusion micro metallurgic examinations, according to ISO 17025

non destructive UT/MP/LP tests carried out by experienced and qualified SNT-TA-1A operators

fixed and portable Brinell/3000/10 hardness check equipment

dedicated and certified equipment for dimensional controls.