Description

Jiangsu Liangyi professional manufacturer of AMS 5644 open die forging parts and seamless rolled steel forged rings from china

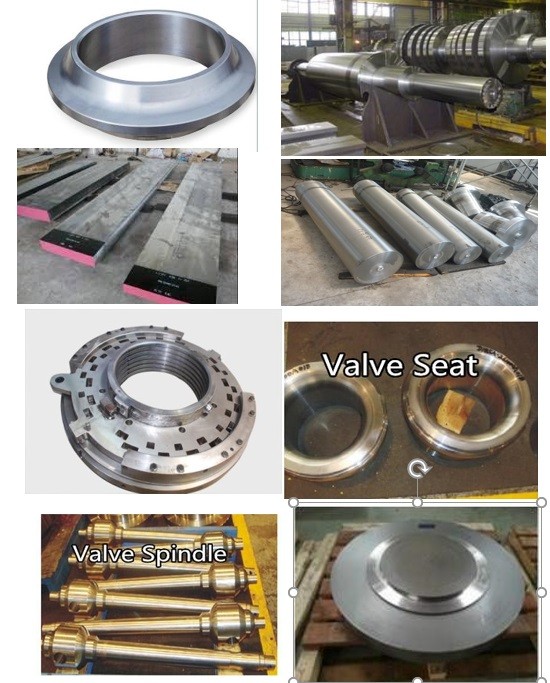

Following is the shape of AMS 5644 forging steel material that we could do is:AMS 5644 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,AMS 5644,Forged forging steel rings seamless rolled rings,AMS 5644 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,AMS 5644 Forged Forging Steel Discs Disks Blocks plates,AMS 5644 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of AMS 5644 material that is used in following industry

AMS 5644 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

AMS 5644 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

AMS 5644 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

AMS 5644 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

AMS 5644 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

AMS 5644 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate pump

AMS 5644 Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

AMS 5644 Forged Forging Block Adaptor

AMS 5644 Forged Forging venturi cone meter Body Bodies Blocks

AMS 5644 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

AMS 5644 Forged Forging turbomachinery turbo centrifugal compressor Impeller,

AMS 5644 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings

AMS 5644 is a a precipitation hardening stainless steel that provides high strength and hardness, excellent fatigue properties, good corrosion resistance, good formability, and minimum distortion upon heat treatment.

AMS 5644 provides valuable property combinations particularly well suited for aerospace applications. This special alloy also provides benefits for other applications requiring high strength and good corrosion resistance, as well as excellent properties for flat springs at temperatures up to 315°C (600°F ).

AMS 5644 forging parts is widely use in used on valve parts, tanks, springs, spring washers, food knives, diaphragms, low and high temperature parts, heat exchangers, special fittings and installations, machine constructions and components. Steel is intended for the aerospace, petroleum, chemical and petrochemical industries, energy, food and cryogenic industry in the form of strips, wires, sheets and bars.

Macrostructure of AMS 5644 forging steel [arts is as follow

Visual examination of transverse full cross-sections from AMS 5644 forged bars, billets, and stock for AMS 5644 forging, AMS 5644 forged rings, orextrusions, etched in hot hydrochloric acid in accordance with ASTM A 604, shall show no pipe or cracks. Porosity,segregation, inclusions, and other imperfections shall be no worse than the macrographs of ASTM A 604

- MACROSTRUCTURE LIMITS of AMS 5644 forging materialis as follow

Class Condition Severity

1 Freckles A

2 White Spots A

3 Radial Segregation A

4 Ring Pattern B

FOllowing is chemical compostion of AMS 5644 forged steel pipes

C 0.09 max

Mn 1.00 max

Si 1.00 max

P 0.040 max

S 0.030 max

Cr 16.00-18.00

Ni 6.50-7.75

Al 0.75-1.50

Following of AMS 5644 forging parts mechnical property :

ageing treatment condition Tensile:min 170KSI,Yield Strength:min 140KSI,Elongation:min 6%,Reduction:min 25%

FOllowing is testing standard of our AMS 5644 forged steel turbine blade flat bats

ASTM E10-12: Standard Test Method for Brinell hardness of Metallic Materials;

ASTM A370-12: Standard Test Methods and Definitions for Mechanical Testing of Steel Products;

ASTM E23-07a: Standard Test Methods for Notched Bar Impact Testing of Metallic Materials;

AMS 2315G: Determination of Delta Ferrite Content,

ASTM E45-05: Standard Test Methods for Determining the Inclusion Content of Steel,

ASTM E112-10: Standard Test Methods for Determining Average Grain Size,

ASTM E837: Standard Test Method for Determining Residual Stresses by the Hole-Drilling Strain-Gage Method,

For our finished production of AMS 5644 forged steel bars should have following inspection report

Identification number, material number and designation, order number, drawing number,

Specification Number;

- Heat number, heat chemical analysis, melting method and product chemical analysis;

- Certificate of heat treatment including method of cooling, actual part temperature, holding

time, cooling condition and all re-heat-treatments by complete graphic temperature time;

- Nondestructive testing records,

- Results of all Mechanical Tests,

-Results of residual stress measurements (for process qualification),

- All probable deviation reports,

- Certification of NDT inspector,

- Dimensional and visual inspection report,

- Cleaning Verified

Welcome your inquiry of AMS 5644 forging forged steel parts

Following is the shape of AMS 5644 forging steel material that we could do is:AMS 5644 Forged Steel round bars square bars Flat bars Rectangles Bars Rods,AMS 5644,Forged forging steel rings seamless rolled rings,AMS 5644 Forged Forging Steel Hubs housing shell Sleeves Bushes Bushing Cases Hollow Bars,AMS 5644 Forged Forging Steel Discs Disks Blocks plates,AMS 5644 Forged Forging Steel Pipe Tubes Tubings Piping Shells Casings Case barrels Housings.

Following is forging products of AMS 5644 material that is used in following industry

AMS 5644 Forged Forging Gas Compressor Turbine Blades steel Flat Rectangles Bars

AMS 5644 Forged Forging Gas steam turbine disks, turbine impeller,turbine blisk,turbine discs

AMS 5644 Forging Steel Forging Forged Gas Steam Turbine Doubled-headed Double end Studs Fasteners Bolts

AMS 5644 Forging Steel gas steam Turbine Guide Rings,seal rings Labyrinth Rings Packing Seal Diaphragm & Seal Ring Rotor End Rings contours Casing Rings

AMS 5644 forged forging steel pipes tubes shells piping tubing barrels housing, tube sheets, nozzles, channel flanges for boiler, heat exchanger,pressure vessel,reactors, heaters

AMS 5644 Forged Forging Valve Balls,valve Bonnets,valve Body Bodies ,valve Stems,valve closures, valve seat rings, valve core, valve discs,for H type two way 2‐way one way back pressure valves, ball valve,check valve,gate pump

AMS 5644 Forged Forging Steel nuclear Power reactor coolant pumps Rotor Impellers

AMS 5644 Forged Forging Block Adaptor

AMS 5644 Forged Forging venturi cone meter Body Bodies Blocks

AMS 5644 Forged Forgig Steel nuclear reactor coolant pump Casing Shells body bodis blocks,nuclear reactor coolant pumps containment seal chamber Rooms,nuclear reactor coolant pumps containment seal chamber Rooms

AMS 5644 Forged Forging turbomachinery turbo centrifugal compressor Impeller,

AMS 5644 Forged Forging Steel PUMP Casing cover.PUMP BARREL,pump impeller,pump shafts, pump housing, pump shells,pump body,pump wear rings

AMS 5644 is a a precipitation hardening stainless steel that provides high strength and hardness, excellent fatigue properties, good corrosion resistance, good formability, and minimum distortion upon heat treatment.

AMS 5644 provides valuable property combinations particularly well suited for aerospace applications. This special alloy also provides benefits for other applications requiring high strength and good corrosion resistance, as well as excellent properties for flat springs at temperatures up to 315°C (600°F ).

AMS 5644 forging parts is widely use in used on valve parts, tanks, springs, spring washers, food knives, diaphragms, low and high temperature parts, heat exchangers, special fittings and installations, machine constructions and components. Steel is intended for the aerospace, petroleum, chemical and petrochemical industries, energy, food and cryogenic industry in the form of strips, wires, sheets and bars.

Macrostructure of AMS 5644 forging steel [arts is as follow

Visual examination of transverse full cross-sections from AMS 5644 forged bars, billets, and stock for AMS 5644 forging, AMS 5644 forged rings, orextrusions, etched in hot hydrochloric acid in accordance with ASTM A 604, shall show no pipe or cracks. Porosity,segregation, inclusions, and other imperfections shall be no worse than the macrographs of ASTM A 604

- MACROSTRUCTURE LIMITS of AMS 5644 forging materialis as follow

Class Condition Severity

1 Freckles A

2 White Spots A

3 Radial Segregation A

4 Ring Pattern B

FOllowing is chemical compostion of AMS 5644 forged steel pipes

C 0.09 max

Mn 1.00 max

Si 1.00 max

P 0.040 max

S 0.030 max

Cr 16.00-18.00

Ni 6.50-7.75

Al 0.75-1.50

Following of AMS 5644 forging parts mechnical property :

ageing treatment condition Tensile:min 170KSI,Yield Strength:min 140KSI,Elongation:min 6%,Reduction:min 25%

FOllowing is testing standard of our AMS 5644 forged steel turbine blade flat bats

ASTM E10-12: Standard Test Method for Brinell hardness of Metallic Materials;

ASTM A370-12: Standard Test Methods and Definitions for Mechanical Testing of Steel Products;

ASTM E23-07a: Standard Test Methods for Notched Bar Impact Testing of Metallic Materials;

AMS 2315G: Determination of Delta Ferrite Content,

ASTM E45-05: Standard Test Methods for Determining the Inclusion Content of Steel,

ASTM E112-10: Standard Test Methods for Determining Average Grain Size,

ASTM E837: Standard Test Method for Determining Residual Stresses by the Hole-Drilling Strain-Gage Method,

For our finished production of AMS 5644 forged steel bars should have following inspection report

Identification number, material number and designation, order number, drawing number,

Specification Number;

- Heat number, heat chemical analysis, melting method and product chemical analysis;

- Certificate of heat treatment including method of cooling, actual part temperature, holding

time, cooling condition and all re-heat-treatments by complete graphic temperature time;

- Nondestructive testing records,

- Results of all Mechanical Tests,

-Results of residual stress measurements (for process qualification),

- All probable deviation reports,

- Certification of NDT inspector,

- Dimensional and visual inspection report,

- Cleaning Verified

Welcome your inquiry of AMS 5644 forging forged steel parts